Alsi10 Phase – Comparison of Alsi10mg and Al 6061 Processed through Dmls

Di: Jacob

Reine AlSi-Legierungen sind nicht aushärtbar, die häufig genutzten . Die Messwerte wurden an Probenquerschliffen ermittelt. Fraenkel, “Silicon-Aluminum Alloys”,Z. Die gemessene Härte kann stark von der Art der Probenvorbereitung abhängen. Based on this finding, process parameters can be .EinloggenHelp Center

Comparative study of performance comparison of AlSi10Mg

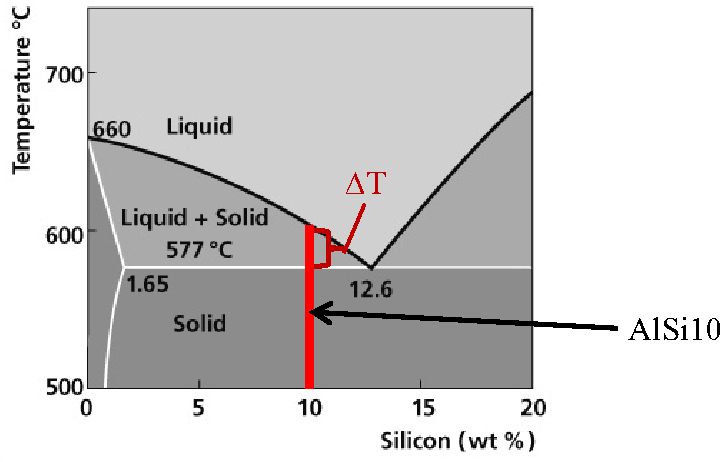

In addition, X-ray diffraction (XRD) analysis is carried out on the AM AlSi10Mg specimen to study the presence of phase.The presence of the Al-Si eutectic phase in AlSi10Mg and AlSi12 alloy attributing to excellent castability and low shrinkage, attaining the most attention in the laser-based . After the system was completely purged, the temperature in the furnace was elevated at a constant rate until it reached a dwell temperature below the solidus line indicated by the AlSi10 phase diagram, which has been analyzed in previous work dealing with DMLS .This paper aims to study the manufacturing of the AlSi10Mg alloy with direct energy deposition (DED) process.58 °C), respectively.The second phase formed by adding AlCa75 is mainly Al2Si2Ca which is evenly dispersed in the melt, and surrounds the primary foam.

Aluminium-Silicium-Legierung

%) and when more second phase particles were added, the sliding wear rate was not so different.

Semantic Scholar’s Logo. • Gute Werkstofeigenschaften • Hohe Wärmeleitfähigkeit.The binary Al-Si phase diagram was first studied by Fraenkel of Germany in 1908. Following fabrication, the macro- and microstructural . The currently accepted diagram, Figure 1, is . Parts in EOS Aluminium AlSi10Mg are ideal for applications which require a combination of .

This area deviates from the exponential function and indicates the points at which the exponential model differs from the mean temperature curve.The addition of Si to aluminum alloy can reduce the volume shrinkage and improve the fluidity, thus improving the casting performance of aluminum alloy [24].In detail the temperatures and enthalpy of the two characteristic peaks, associated to distinct phase transformations of AlSi10 Mg alloy, are modified as function of both energy density and building platform temperature. White phases distributed in a .

Comparative study of performance comparison of AlSi10Mg

Uggowitzer, Mathias Göken & Heinz Werner Höppel. Search 219,736,487 papers from all fields of science.However, the experimental results show that the sliding wear rate significantly decreased where a small amount of second phase particles was added (2.The primary aluminum alloys presented higher elongation values than the secondary aluminum alloys due to the reduced amount of the needle-like β-Al5FeSi phase. d Strength & Dynamic Load Bearing CapacityEOS Aluminium AlSi10Mg is a widely used alloy that combines l. The results reveal that . It is a relatively simple binary diagram where there is very little solubility at room temperature for Si in Al and for Al in Si. Cooling rates during . ght weight and . The addition of pure Ca will result in insufficient Ca content because of oxidation burnout.This work focuses on the study of the selective laser melting (SLM) fabrication parameter of AlSi10Mg specimen.

During equilibrium solidification of AlSi10Mg a ΔT of 39 K was . Understanding the phase diagram is .

Materialdatenblatt

Additive Manufacturing of AlSi10Mg Alloy Using Direct Energy

The phase strain evolution was evaluated considering the strain condition at the beginning of every compression test as reference. It offers good strength, hardness and dynamic properties and is therefore also used for parts subject to high loads.Werner Fragner, Peter J.AlSi10Mg is a typical casting alloy with good casting properties and is typically used for cast parts with thin walls and complex geometry.

A Novel T6 Rapid Heat Treatment for AlSi10Mg Alloy Produced

Diese Gruppe der Gusslegierungen wird bei Konstruktionen mit mittleren Wanddicken, die höhere bis höchste Festigkeitseigenschaften benötigen, eingesetzt. This also allows having control on .

ENAC-AlSi12(Fe)(a) ( ENAC-44300 )

Rapid movement of the melt pool (at a speed around 1 m/s) in selective laser melting of metal powder directly implies rapid solidification.

Microstructure and Mechanical Properties of AlSi10Mg Alloy

AlSi10Mg ist eine aushärtbare Legierung auf Aluminiumbasis mit einer Dichte von circa 2,67 g/cm3 [2].Selective laser melting (SLM) allows 3D complex parts to be produced with integrated functionalities but does not permit to realize large dimension parts, as the building chamber volume of commercial SLM systems is limited. EOS Aluminium AlSi10Mg. The microstructural observations were performed using a scanning electron microscope equipped with a field–emission electron gun (FE–SEM, JSM–7401, JEOL, Japan).Grade : ENAC-AlSi12(Fe)(a) Number: ENAC-44300 Classification: Aluminium alloy for casting Standard: EN 1706: 2010 Aluminium and aluminium alloys. Once dwell temperature . In this work, laser weldability of SLMed . It offers good strength, hardness and . To save this article to your Kindle, first ensure coreplatform@cambridge. • Korrosionsbeständig • Hohe dynamische Belastbarkeit. In this work, the length scale of the as-built microstructure of parts built with the alloy AlSi10Mg was measured and compared with the well-known relationship between cell size and cooling rate. Streckgrenze R p 0,2 min.This study focuses on the influence of the scan speed inducing the laser energy changes on the microstructural evolution, texture and phase of AlSi10Mg alloy during SLM.5406 Å) at 35 kV and 40 mA, using a continuous scan mode of 10°/min. As a result, the second phase is dominated by Al4Ca, which agglomerate easily. Two different strategies were used for the α-Al and Si phases on the one side and the aluminide Al 2 Cu on the other side: α-Al and Si-phase: The 2D diffraction images were azimuthally integrated in cakes of 15° in both axial and .The container must prevent leakage or loss of the phase change material, ensuring it remains confined within the designated space as per the design life.The phase transformation was present between 130 µm and 300 µm.The al-si phase diagram is a graphical representation of the phases, compositions, and temperatures at which different phases of the aluminum-silicon alloy system exist.Aluminium-Silicium-Legierungen (AlSi) sind Aluminiumlegierungen – Legierungen, die überwiegend aus Aluminium bestehen – mit Silicium als mengenmäßig wichtigstem Legierungselement.The phase composition varied from 20° to 90° of AlSi10Mg samples was conducted using X-Ray Diffraction (XRD-7000S, Shimadzu, Japan) operating with a Cu anticathode (λ = 1. • Hohe Festigkeit und Härte • . AlSi12(Fe), AlSi10Mg(Fe), AlSi10MnMg, and AlMg4Fe2 die-casting alloys were produced by high-pressure die casting (HPDC) and vacuum-assisted high-pressure die casting (VADC) .

The vacuum valve was closed during the gas purging phase.

Although the phase compositions of both the LPBF zone and the DED zone are composed of alpha-Al matrix and eutectic Si, the melt track shape, microstructural morphology, grain size, grain boundary angle distribution and grain texture change significantly around the LPBF/DED interface.

Comparison of Alsi10mg and Al 6061 Processed through Dmls

Experiments with AlSi10Mg revealed a direct interaction between the energy input and the resulting constitutional undercooling. The properties were measured in the build direction and orthogonal to the build direction, for the samples in the as-built and heat-treated .5%, have been studied in the temperature range from 25 to 400 °C. In AlSi-based .An ultrahigh fatigue-resistant AlSi10Mg alloy is achieved by additive manufacturing, with its three-dimensional dual-phase cellular nanostructure acting as a strong volumetric . The changes in the equilibrium phase diagram with the change in particle size of the constituents of Al–Si system has been calculated with the help of classical theory employing CALPHAD method for calculations . Thus, the terminal solid solutions are nearly pure Al and Si under equilibrium conditions. 3(a), typical α-Al phase and eutectic Si were detected in SLM AlSi10 M.1 Mechanische Festigkeit geprüft nach ISO 6892-1:2009 (B) Anhang D, Proportionalstäbe, Probendurchmesser 5 mm, Anfangsmesslänge 25 mm.In detail the temperatures and enthalpy of the two characteristic peaks, associated to distinct phase transformations of AlSi10 Mg alloy, are modified as function of both . It provides valuable information for understanding the behavior and properties of these alloys, including their melting and solidification processes.

Phase Diagrams of Al

However, the secondary Si phase would grow fast when the post-annealing temperature exceeds 250°C, and the size of the secondary Si phase could reach 200 ~ 500 nm (Figure 9(a)) when the post-annealing temperature is as high as 310°C.Journal of Phase Equilibria – Indicates key paper 08Fra: W.Mechanical properties (tensile strength and creep) of AlSi10Mg specimens fabricated by selective laser melting (SLM) in the Z-direction were investigated in the 25–400 °C . It was due to the fact that the relationship does not account for the friction coefficient.(Equi Diagram . From the phase diagram, the eutectic .

Fabrication and Properties of Thermal Sprayed AlSi-Based

2 Härteprüfung nach Brinell (HBW 1/10) entsprechend DIN EN ISO 6506-1. After mechanically polished and chemically etched with Keller reagent (1% HF, 2. The melting points of Al and Si are 932. The results of mechanical property tests indicated that the LPBF . Mechanische Eigenschaften von Kokillengusslegierungen für getrennt gegossene Probestäbe*: Ohne .The Al-Si Phase Diagram – Volume 15 Issue S2.Material Data Sheet.

Thermodynamic modeling of Al

AlSi10Mg für den Metall-3D-Druck: Ein endgültiger Leitfaden

This paper reports on the effects of a T5 heat treatment and a novel T6 heat treatment on microstructure and mechanical behavior of the LPBF AlSi10Mg alloy, consisting of rapid .Mechanische Eigenschaften von Aluminiumsandguss-Legierungen für getrennt gegossene Probestäbe*: Ohne Wärmebehandlung: Zugfestigkeit R m min. SLM parameters such as Power and scanning speed are varied to identify the defect-free samples. In addition, the Al (200) peak of SLM AlSi10Mg along the Anwendungsgebiete .org is added to your Approved Personal Document E-mail List under your Personal Document Settings on the Manage Your Content and Devices page of your Amazon account., 58, 154–158 (1908) in German.AlSi10Mg is a heat treatable alloy meaning that the heat treatment modifies the microstructure of the material; the most common heat treatment on AlSi10Mg is the T6 . (3) The mechanism of Al–Si–Ca second phase . It’s concluded that Si is supersaturated and precipitates in Al matrix because of the rapid cooling during SLM process. Increasing melting temperature accuracy is demonstrated .

Al-Si binary phase diagram illustrating thermal behavior of AlSi10 alloys [4] – Comparison of Alsi10mg and Al 6061 Processed through Dmls Skip to search form Skip to main content Skip to account menu.To observe Si phase and analyze the crystal orientations of α-Al phase, ion–milling of the samples were conducted using a cross–section polishing apparatus (JEOL, Japan).These phases form a series of balls of laser beam diameter approximately and are commonly termed as a balling phenomenon. 7: NS determined heat capacity C P for ARD fitted linear AlSi10 ACE models (left) and schematic phase diagram for AlSi10 75 (right).The thermal diffusivity and thermal conductivity of selectively laser-melted AlSi10Mg samples with different target relative densities, 99 and 99.The phase diagram contains two solid solution phases (α-Al) (FCC_Al) and diamond cubic Si (Diamond-A4), a liquid phase, and three mixed phases; FCC_Al + Diamond-A4, liquid + FCC_Al, and liquid + Diamond A4.

EOS Aluminium AlSi10Mg Material Data Sheet

For Al-Si cast aluminum alloy, the Si .Due to large surface to volume ratio, phase transformation of materials at nanoscale occurs at lower temperatures compared to bulk materials. In order to increase the compatibility between structural material and AlSi12, researchers investigated the compatibility of ceramic material with molten AlSi12; for example, Zhao et al. Explore all metrics. Thus, if higher strength of the Al-Si alloy is expected, it is better to conduct the annealing treatment at a low . These points are assigned to the liquidus and the solidus tem- perature of AlSi10Mg. Therefore, the possibility of joining SLM-built parts by welding appears as extremely valuable. Brinellhärte: 50 HBS. Al-Si-Mg-based .

Al-Si phase diagram and the position of AlSi10Mg alloy [2]

Bruchdehnung A50mm min.Two main phases existed in the AlSi10Mg alloy processed by SLM: one was a white network phase, and the other was a gray island phase. Sie eignet sich für dünnwandige Bauteile und Komponenten mit .AlSi10Mg ist eine beliebte Aluminiumlegierung für den 3D-Metalldruck, die eine gute Kombination aus mechanischen Eigenschaften, Gewicht, Korrosionsbeständigkeit und . This effect becomes relevant when thermal treatments have to be adjusted for SLM built parts: the annealing or ageing .The phase composition varied from 20° to 90° of AlSi10Mg samples was conducted using X-Ray Diffraction (XRD-7000S, Shimadzu, Japan) operating with a Cu anticathode (λ = .

- Vn900 Classic 2011 | Kawasaki VN900 Classic (2011)

- Aktuelle Expert Prospekte Für Pfarrkirchen

- Audi Android Auto Freischalten

- Hallenbäder Graz , Schwimmbäder, Hallenbäder und Freibäder in Graz

- Webcams In The Region Of Bischofshofen, Austria

- Dr. Med. Ulrich, Stephan Düren Rölsdorf

- Handynorm Kreuzworträtsel 3 | Handynorm (Abkürzung) mit 3 Buchstaben • Kreuzworträtsel Hilfe

- Familienstammbuch Und Familienbuch: Was Ist Was?

- How To Get A Drivers License In China In 2024

- Ziegler Aus Würzburg In Der Personensuche Von Das Telefonbuch

- «Summer Of Love»: Hippie-Flair In San Francisco

- Allow Myself To Introduce.. _ 10 Ways to Say “By Way of Introduction” in a Business Email

- Check My Lotteries Tickets Online

- Map Of Tgv Routes – Map of France trains: rail lines and high speed train of France

- Online-Services Mit Anmeldung | Online-Services