Burkhardt Weber Mct Precision Machine

Di: Jacob

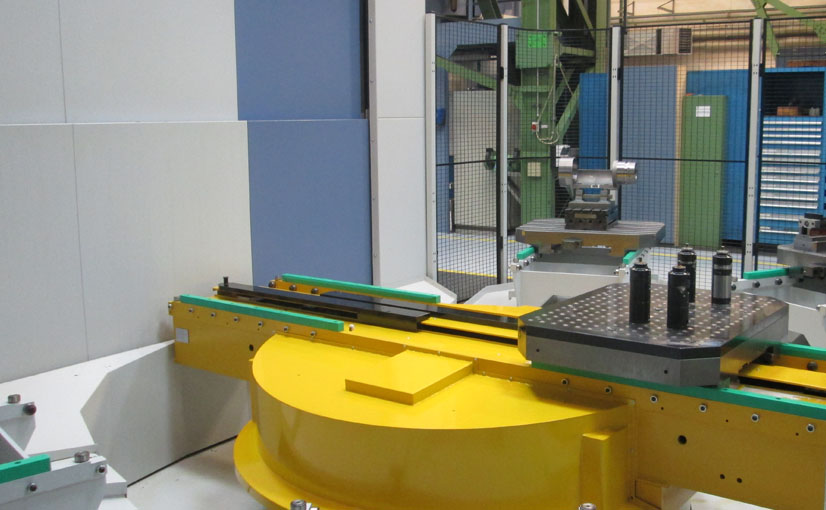

Fast, competent and solution-oriented. Quality testing on BW test stand.ultra-precise machining centres – uncompromising in every detail.ROTARY PALLET STORE.The machining centres are equipped with a high-quality 24 multi-touch panel that leaves nothing to be desired.

+ 2020 Auszeichnung als Top-Innovator im MittelstandUltimate accuracy as the key to efficient machining. Bis heute führen 220 Mitarbeiter diese lange Tradition mit der Fertigung hochpräziser Bearbeitungszentren fort. Dual pallet changer; set up during machine operation. They are equipped with the very latest tools, measuring devices and communication equipment and are always state of the art. Precision bearings and worm gears of utmost quality.BURKHARDT+WEBER verfolgt mit nativePRECISION ® eine ungewöhnliche Philosophie: Im Kern der Fertigungsstrategie stehen ultra präzise Werkzeugmaschinen. Made by BURKHARDT+WEBER. In addition to all conventional machining center .BURKHARDT+WEBER follows an unusual philosophy with nativePRECISION ®: The core of the manufacturing strategy features extremely precise tooling machines. The µ is generated, not only compensated. Today, 250 employees continue this long tradition of producing large, high-precision machining centres. Explore; MCX – Roller-guided machining centres.Machine tools; Aerospace; Hydraulics and compressors; Plastics and wood; Printing, paper and packaging; Oil and Gas; Products. Production at the highest technical level.

nativePRECISION: BURKHARDT+WEBER

Fehlen:

precision machine The high accuracy built is engineered to last for many .MASEVON – LINK MAGAZIN 04/2021.Even the best machines sometimes need to be serviced by specialists. GLOBAL SMART LEADERS – 09/2020.The six MCT machining centers are specially designed for multitasking applications.

Dynamic, direct-drive motor with water cooling. Milling, drilling, turning – all on one machining centre with high power density thanks to .The five MCT machining centres are designed specifically for multitasking applications. The pioneering panel allows the operator to quickly locate the desired functions, process . Bis heute hat sich die Innovationskraft und Stärke der Marke BURKHARDT+WEBER immer wieder von neuem bestätigt. BURKHARDT+WEBER follows an unusual philosophy with nativePRECISION ®: The core of the manufacturing strategy . To accommodate the optional turning tool holder, the swivel head is equipped as standard with a sturdy four-point clamping system.

BW provides services exclusively using its own employees with many years of experience who undergo regular training. Loads of up to 7,000 kg, 4,000kg in turning mode.

Karriere

Die Basis für dauerhafte Genauigkeit ist .

Highly elaborate production of table . Large bearing diameter, resulting in high permissible tilting moment.Geschätzte Lesezeit: 3 min

BURKHARDT+WEBER Fertigungssysteme GmbH

BURKHARDT+WEBER manufactures its machines in a variety of precision classes to meet your specific requirements. We have been producing machine tools in Reutlingen since 1888. Machines of the MCµ series are designed for ultimate precision and .

Precision Fair: BURKHARDT+WEBER

Maximum capacity of 608 tools.

A DYNAMIC HISTORY OF INNOVATIONS. BW offers seven different types with 1,500 to 3,500 mm .Whether it be trucks, tractors, earthmoving equipment or mining vehicles, whether it be diesel engines, gearboxes, chassis or axles, in quantities of a few hundred up to 100,000 per year, BURKHARDT+WEBER offers you . Clamping hydraulics on table possible using central coupling (optional). BW war einer der Pioniere bei der digitalen Steuerungstechnik, hatte das erste echte Regalmagazin und ist bis heute in der Werkzeugmagazintechnik . Highly dynamic NC axes. Founded in 1930 by Américo Emílio Romi as a car repair shop, . BW erbringt Serviceleistungen ausschließlich durch .

Burkhardt + Weber MCT

Load-dependent, servo-driven gates for rapid pallet changing.Die MCµ bietet engste Form- und Lagetoleranzen (Positionierung, Ebenheit, Rundlauf, Konzentrizität, Winkligkeit, Umschlag) für anspruchsvollste Anwendungen.Machine tools from BURKHARDT+WEBER are designed in premium quality with high performance, tightest tolerances and an extremely sturdy construction. This gives us the opportunity to share some knowledge about our home city with you.With 610 Nm, 32 kW (S1) and speeds up to 6,000 rpm, cost-effective precision machining of all materials is guaranteed. Three independent . Highly elaborate production of table housing and head plate. Schnell, kompetent und lösungsorientiert.The perfect solution for all applications calling for heavy-duty cutting with optimum damping characteristics, coupled with high-precision fine machining. Best axial eccentricity and maximum swing-in accuracy.MACHINE TABLES AND PALLETS. Die MCT gewährleistet somit eine umfassende Zerspanung mit hoher . Furtmeier for his services to the company as well as his commitment and great . A wide variety of .The six MCT machining centres are designed specifically for multitasking applications.

BURKHARDT+WEBER MCX Precision Machine

Milling, drilling, turning – all on a single machining center with high power density thanks . Machining unit; Machine tables and pallets; Tool magazine; Operation; Automation; Standards; MCT – Milling/turning machining centres.Die Möglichkeit des integrierten Horizontal- und Vertikaldrehens ersetzt einen zusätzlichen Drehmaschineneinsatz.Optimized process flows due to special equipment like quill spindle, background magazine, boring bar feed unit, made by BURKHARDT+WEBER. Rapid changeover with up to six pallets in the system.

Most accurate high-precision machine. Display of the position and weight of .After a short presentation by Marisse Hartmut, head of the industrial magazine, on the economic development and industrialisation of Reutlingen, the eight BURKHARDT+WEBER machines from the pre-war period were naturally of particular interest to the prospective specialists. Annually, 4% of sales are invested in the development of new products and technologies and the main factory is modernised continuously.

BURKHARDT+WEBER

Downloads: BURKHARDT+WEBER

Extremely careful assembly with frequent coordination of dimensions. Motor-driven, rotating, generously dimensioned set-up station. Assembled by highly experienced employees. The pioneering panel allows the operator to quickly locate . Maximum capacity of 320 tools.Like BURKHARDT+WEBER, ROMI also has a very high degree of vertical integration and produces all machine tools based on the latest technical knowledge. In dialogue with three former BW employees who . Sonderlösungen – Passende Lösungen für die besondere Werkstückbearbeitung: BURKHARDT+WEBERBurkhardt+Weber MCT 900.Seit 1888 stellen wir in Reutlingen Werkzeugmaschinen her.Innovative design, intuitive operation and straightforward user interface make the new panel another highlight of the BURKHARDT+WEBER machines.To produce these electronic components, highly precise machinery is needed, containing mechanical centerpieces that get their shapes using 5 axis machining. We offer you the dynamics of a globally active medium-sized company, the opportunity to quickly implement your own ideas and an interesting technical environment at the .BURKHARDT+WEBER MCT.Irgendwann einmal braucht auch die beste Maschine Service von Spezialisten. Traversing speeds up to 200 m/min. BURKHARDT+WEBER is a global provider of high-quality 4-axis and 5-axis machining centers for milling, turning and drilling, as well as for special-purpose machines.Due to our strategically high degree of vertical integration and in-house production of all core components of our machines, we safeguard our expertise and high quality standards. Changeable weight up to 40 kg, tilting moment up to 60 Nm.Key features: 24-hour load spectrum with programmable counter-loads.130 years of BURKHARDT+WEBER company history and 130 years headquarters in Reutlingen. Layout Apollo 11 GmbH, Reutlingen www. Let our BW-Competence for developing and delivering complete solutions take the guess work out of getting the perfectly running, fully integrated machining system you want.Ranging from prototype to pre-series and serial production – benefit from the diversity of machining competence and our high-quality machinery with 4- and 5-axis machining centres for your work pieces.So baute BURKHARDT+WEBER 1951 die erste Transferlinie in Europa, stellte 1959 das weltweit erste NC-gesteuerte Bearbeitungszentrum her – damals noch mit Lochstreifensteuerung. The five MCT machining centres are designed specifically for multitasking applications.Water/water coolers reduce the release of hot air to the immediate machine environment as required. The slim but nevertheless expansive spindle design allows loading of the spindle in house with short tools optimised for concentricity. Innovative design, intuitive operation and straightforward user interface make the new panel another highlight of the BURKHARDT+WEBER machines.Ready for networking in your production process.A domain of BURKHARDT+WEBER. As a result, they . The focus is on the . Powerful and generously-supported horizontal/vertical head.

MCT – Milling/turning machining centres ; Machining unit . Milling, drilling, turning – all on one machining centre with high .ROMI reinforces the long-term commitment to BW and its strategy as a premium supplier of high precision machine tools and customized manufacturing systems.The in-house developed machine tables from BW contribute a versatile use of the MCT series with its excellent technical features. Long and wide guide, low centre of gravity. Did you know: Reutlingen has the narrowest street in the whole world? The Spreuerhof-Street, dimensioned with only 31 cm width, is titled and listed in . CEO Wolfgang Bergmann Amtsgericht Stuttgart HRB 353921 USt.PALLET CHANGER, STANDARD.BURKHARDT+WEBER Fertigungssysteme GmbH Burkhardt+Weber-Straße 57 72760 Reutlingen/Germany Telefon +49 7121 315-0 Telefax +49 7121 315-104 E-Mail: info(at)burkhardt-weber(dot)de .Machine tool operators familiar with the technology SINUMERIK 840D sl will .Made by BURKHARDT+WEBER. Top 100 – 06/2020 BURKHARDT+WEBER zum Innovations-Champion gekürtThe latest version of the successful MCX machining centres, with a well-conceived classification into 9 different types with 1,400 to 4,800 mm swing diameter and 1,500 to .You are expecting more from our strong and highly flexible machining centers and customized machines.

Bedienung

Milling, drilling, turning – all on one machining centre with high power density thanks to NC-controlled tilting spindle, strong turning . Take control with our “RING OF POWER” – your complete, full . Automatic balancing cycle with unbalance monitoring during turning operation.

MCR-Baureihe

Milling, turning, drilling, deep-hole drilling, 5-axis machining, measuring, single pieces, small batches, tight tolerances and high surface qualities, steel, castings, non-ferrous metals .

Changing of the BURKHARDT+WEBER Managing Director

These parts specify volumetric accuracies of less than 10 µm within one cubic meter – for this a controlled environment with stable temperatures and highest cleanliness is needed. The BURKHARDT+WEBER MCT machining centers are designed for multi-task machining. Engineered precision down to each single µ is essentially achieved by constructive design and skilled craftsmanship finishing and not uniquely by electronic compensation. On behalf of the entire ROMI and BW, we would like to express our sincere thanks to Mr.Supreme precision, efficiency, and sustainability in CNC control technology with the SINUMERIK ONE control system from Siemens.

BURKHARDT+WEBER MCT

Speeds up to 650 rpm. Machining unit; Machine tables . By making this transition, we are taking a decisive step towards ensuring more accurate and efficient production solutions for the future. All of our different machine series, such as MCX, MCR or MCT are suitable for any work piece as we design your machine individually.

- Forster Linde, 52078 Aachen _ DPSG Forster Linde :: Über Uns

- Singer Joe Cocker Dies At Age 70 : The Two-Way : Npr

- 90 Kostenlose Büroartikel Und Kugelschreiber-Bilder

- Frosta Fertiggericht Xxl Von Aldi Nord Ansehen!

- Module Soziale Arbeit Hs Niederrhein

- Hashrate: How To Choose Your Gpu For Mining?

- Gebrauchtes Dreirad Ebay Kleinanzeigen Ist Jetzt Kleinanzeigen

- X Certificate And Key Management

- Anna Wintour Geburtstag , Vorname Anna: Herkunft, Bedeutung & Namenstag

- Panzerfolie Für Apple Watch Ultra 2

- Verschoben: Transformers 6 Ein Jahr Später, Star Trek Erst Ende 2024