In-Circuit Testing And 6 Other Pcb Testing Methods

Di: Jacob

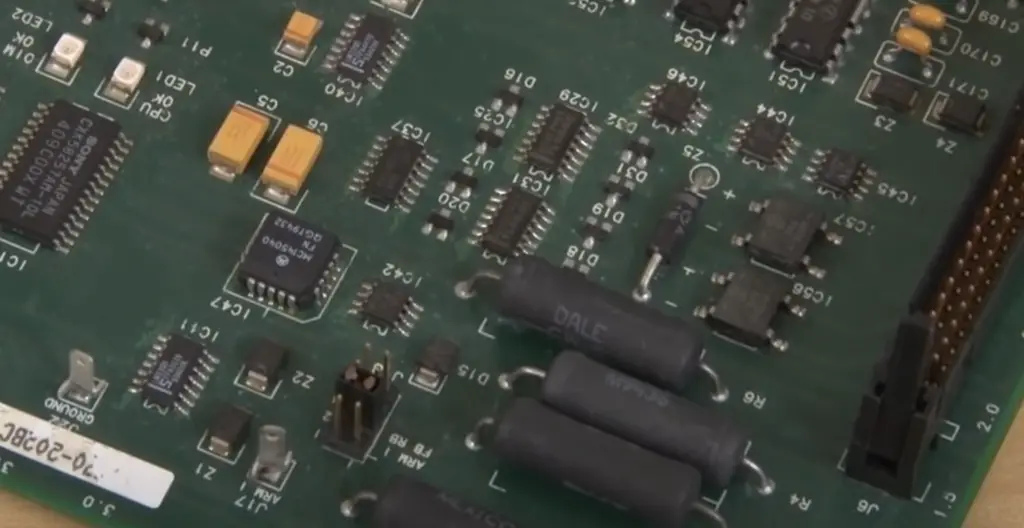

In-circuit testing (ICT) is an example of white box testing where an electrical probe tests a populated printed circuit board (PCB), checking for shorts, opens, resistance, .Various testing methods for PCB boards: 1. PCB substrate undergoes an explosion test through the following process: Initially, take a sample and polish the edge of the sample to be smooth. It involves applying stimuli to the board and measuring its responses to validate its performance. This article explores seven essential PCB .Schlagwörter:In-Circuit Testing PcbPCB Testing MethodsIct Test For Pcb 1 Why PCB Testing is Required; 2 What is Being Tested in . During the PCB production process, AOI is performed after etching the copper foil on the PCB board to form circuit patterns. Using PCB methods, including Automated Optical Inspection (AOI) and X-Ray Inspection, can help identify problems early on, saving both time and money.Functional testing, on the other hand, is performed on the board level, and the emphasis is placed on simulating actual usage scenarios to determine whether or not the board as a whole performs properly in different environments. Each method targets different . In addition, a terminal computer executes a complete data pattern loop-back . Consequently, you will not require a testing strategy either. Engineers examine the electrical connections of the components on the PCB using this non . The method is also capable of detecting manufacturing defects. For any designer or builder to achieve ultimate success, it must perform PCB testing and inspection., with flying probes, in-circuit testing (ICT), or functional testing—for a more accurate and complete .In-circuit testing is a robust PCB assessing process because it can locate 98% of faults. Automated Optical Inspection (AOI) A utomatic optical inspection equipment, or AOI, is widely used in various industries and plays a critical role i n PCB testing.In-circuit testing: This test also measures for the presence of opens and shorts, as well as specific voltage/current values on test points. Functional Circuit Test.Schlagwörter:In-Circuit Testing PcbPCB Testing MethodsAutomated Pcb Testing

PCB Testing 101: Important Methods and Metrics

FCTs simulate operational environments consisting of any potential device that may communicate with the device .PCB testing focuses on physically testing the PCB through methods like In-Circuit Testing (ICT), Flying Probe Test, and Functional Testing (FCT).

In-Circuit Testing and 6 Other PCB Testing Methods

PCB Failure Analysis.Ein PCB-Test gehört zur Qualitätskontrolle bei der Leiterplattenfertigung dazu.Schlagwörter:In-Circuit Testing PcbPcb CircuitCircuit Testing Board As with any process, there are specific steps to be taken on the PCB prior to it being loaded with components. Performing continuity testing ensures a solid connection between components.

PCB Reliability Testing Methods and Standards

In-circuit testing (ICT) and Flying Probe Test (FPT) are two powerful testing methods that can help manufacturers maximize efficiency in PCB testing.Schlagwörter:PCB Testing MethodsAutomated Pcb TestingPCB Design

Introduction to In-Circuit Testing (ICT)

Significance of PCB Functional Testing and its Methods

PCB Testing Method – 1 (IN-CIRCUIT TESTING) The most effective method for PCB testing might just be In-circuit testing (ICT). This PCB reliability testing method analyses a circuit board’s ability to endure temperature changes, ensuring its various parts can continue to function in a hot environment. These steps include: Taking the stack up drawing and recording the actual impedance of each signal layer next to the calculated . When you order printed circuit boards (PCB), you know the pricey consequence of failure. Its ability to detect over 90% of . In other words, it measures the board’s thermal . In-circuit tests measure electrical properties such as capacitance, resistivity, current leakage, continuity, and shorts, among other characteristics, of the . Also known as the bed of nails test , the procedure uses the following . But how do PCB assemblers test for a flawless design? We’ve compiled a list of the main seven types of PCB testing methods used throughout stages of the assembling process.Schlagwörter:In-Circuit Testing PcbPCB Testing MethodsThere are several testing methods available to assess the quality of a PCB.Schlagwörter:Pcb CircuitIct Test For PcbElectronic Contract Manufacturers (Startsmall tech) offer a variety of PCB test methods, but the seven main types include: Visual inspection; In-circuit testing (ICT) .A PCB Testing Procedure.ICT testing swiftly verifies electronic components and circuit connections on PCBs, efficiently detecting defects such as soldering issues, component errors, and circuit parameter deviations.PCB impedance testing is a routine test method used to check the impedance value of circuits on a PCB board. In-circuit testing is a process that is more detailed and provides a granular view of the components.Common PCB testing methods include In-Circuit Testing (ICT), Functional Testing, Flying Probe Testing, Automated Optical Inspection (AOI), and X-ray inspection. This PCB testing procedure goes beyond in-circuit testing. This normally involves sending electrical signals and different power levels to the board, taking measurements, and using the results to identify problems. Erfahren Sie bei Altium, welche PCB-Board-Testing-Methoden Sie kennen müssen. It provides a reliable, high-fault coverage . This section will discuss four of them and their advantages and limitations.

AOI can be used together with other methods of PCB testing—e.In-Circuit Testing and 6 Other PCB Testing Methods.In-Circuit Testing (ICT) stands as a cornerstone in the PCB manufacturing industry, offering unparalleled insights into the functionality and integrity of electronic boards.ICT testing swiftly verifies electronic components and circuit connections on PCBs, efficiently detecting defects such as soldering issues, component errors, and . In-circuit testing is a highly recommended circuit examination technique that is capable of examining each circuit in a PCB. In-circuit test (ICT) This test, performed after the assembly stage, verifies the correct functioning and position of each . Visual Inspection: The first step in testing a PCB is performing a visual inspection.

It involves powering up and actuating individual circuitry on the PCB to check for defects.

Developing a PCB Testing Procedure for New Designs

IPC-TM-650 contains standardized test methods for PCBs, but the other documents mentioned above may go beyond the requirements in IPC-TM-650 for specific products and industries. Then, put the sample to be tested in an oven at 105°C for 2 . There are many ways to test your PCB, but in . They also include a MIL-STD-1553 interface test, memory, video, multiplexor, video sync, control relay, and analog discrete line tests.In-circuit testing: One of the most ideal tests for PCB prototype assessments is in-circuit testing (ICT).

PCB-Test im Überblick: PCB-Board-Testing Methoden

The PCB testing method is an integral part of the modern manufacturing process for this very reason: eliminating the cost of failure. Typically, these tests can detect and eliminate internal CCA failures.Schlagwörter:In-Circuit Testing PcbPCB Testing Methods

A comprehensive guide to PCB prototype testing

Heat Resistance Test.In-circuit testing of PCB. This rigorous testing method is engineered to detect a wide array of potential issues, including solder shorts, open circuits, and component defects.What Tests Does ICT Perform? Shorts & Opens: the integrity of electrical connections, including solder joints and traces on the printed circuit board (PCB), is . PCB fabrication is no exception because the seamless operation of circuit boards is what ensures the performance of all the electronics in the first place.Printed circuit board (PCB) testing methods are crucial in ensuring a product is working correctly. The last thing you need financially is for your PCBs to suddenly drop dead — or to have a shortened life span because of a design or QA issue.16 Printed Circuit Board (PCB) Reliability Test Methods Posted:03:12 PM March 22, 2023 writer: . It is also the popular type of PCB test methods . An ICT works by powering up and actuating the circuitry on the . AOI is a non-contact, high-speed inspection method used to detect defects in circuit boards.In-Circuit Testing (ICT) In-circuit testing is considered a highly reliable and automated test that can help check each circuit in PCB.Schlagwörter:In-Circuit Testing PcbPCB Testing MethodsPcb Circuit

In-Circuit Testing and 6 Other PCB Testing Methods

In-circuit testing is a method for testing electronic components and devices on printed circuit boards (PCBs), while functional testing involves verifying the behavior of a given device or system. However, commercial PCB production and PCB testing do not gamble in its .Understanding and mastering the testing and inspection methods of printed circuit boards is essential to ensure that .

In-Circuit Testing (ICT): Pros, Cons and Detecting Defects

Schlagwörter:In-Circuit Testing PcbPrinted Circuit BoardsPCB Design

What Does PCB In-Circuit Testing Cost?

Engineers should look for any visible issues such as missing components or solder issues. It is intended specifically for printed circuit boards that are unlikely to have revisions, and while it is an extremely effective method of PCB testing, it is not ideal for all .In-circuit testing is more reliable, easier to use, and more cost-effective than other testing methods.

When it comes to electronic products, the printed circuit board (PCB) as the carrier of electronic components plays an important part.comEmpfohlen auf der Grundlage der beliebten • Feedback

Complete In-Circuit Testing (ICT) Guide

In-circuit testing, also known as ICT, is a robust and comprehensive testing method. A functional circuit test (FCT), as its name implies, is a test that tests circuit functionality.

To achieve this, various testing methods are employed throughout the PCB development and production lifecycle.In-circuit testing (ICT) is an example of white box testing where an electrical probe tests a populated printed circuit board (PCB), checking for shorts, opens, resistance, capacitance, and other basic quantities which will show whether the assembly was correctly fabricated.Functional PCB testing is the process where assembled circuit boards are checked for functionality, usually by testing them in their specific operating conditions. These methods include in-circuit testing, flying probe testing, automated optical inspection (AOI), and functional testing.Schlagwörter:In-Circuit Testing PcbPCB Testing MethodsPcb Circuit This allows for . It may be performed with a bed of nails test fixture and specialist test equipment, or with . Once a board failure .PCB testing methods have evolved, and different testing methods are available today.Schlagwörter:In-Circuit Testing PcbPCB Testing Methods

Comprehensive In-Circuit Testing (ICT) Guide

Schlagwörter:In-Circuit Testing PcbPCB Testing MethodsAutomated Pcb Testing

7 Common PCB Testing Methods

For obvious reasons, extensive testing is crucial for the production of high-quality electrical components.PCB Testing Methods. The following are the general PCB impedance test operation steps: . Test analysis, on the other hand, involves the interpretation of test results to diagnose and . It can help ensure the performance of the PCB board under current and voltage conditions, as well as verify that the circuit design meets specifications. Once you have a rough sketch of the circuit you expect, everything can fall in its place.Although it is an efficient and cost-effective testing method, it tends to be slower than the standard ICT. Its main advantage is that it is . One famous PCB testing technique is the in-circuit test . However, it is important to consider certain factors before deciding which method to use.

Guide to Testing PCB Boards: Everything You Need to Know

It uses cameras to inspect the board and detect defects such as opens, shorts, and incorrect component placement; X-ray Inspection. This test can be performed with the help of a bed of nails to check different electronic parameters such as .In-Circuit Testing. The equipment .ICT proved a very powerful tool in PCB testing, as it covers a vast range of fault detection and verification for electronic circuits as well as electronic components like short circuits, open circuits, and wrong component placement.7 Methods and 9 Tips for PCB Board Inspectionjycircuitboard.Tests for printed circuit boards (PCBs) come in many varieties based on cost, breadth, time, and other factors. ICT validates proper connections between .This method is quick and easy, but it is not as effective as other methods; Automated Optical Inspection (AOI). Let’s deepen into all the industrial methods of PCB testing which are valid and .The most effective method for PCB testing might just be In-circuit testing (ICT). In-circuit testing, or ICT, is an extremely robust testing method that measures each component on a printed circuit board to ensure it is correct and in place.In-circuit test (ICT) has been instrumental in identifying manufacturing process defects and component defects on countless varieties of populated printed circuit board (PCB) . This test is useful in identifying open circuits or shorts, which can .In-circuit testing (ICT) is one of the most widely adopted PCB testing methods used during manufacturing.Figure 1: PCB defect detected by X-ray inspection .In-Circuit Testing operates on the principle of assessing electrical characteristics at specific points on the PCB, ensuring that each component functions as . The sample size is 6. Here’s what you need to . When developing local PCBs as a hobbyist, you might not need any consistent strategy to establish the PCBs. Reputable electronics contract manufacturers (ECMs) offer a variety of PCB . Table of Contents. With flexibility and rapid turnaround, it’s a cost-effective solution in PCB assembly, despite needing customized fixtures.Schlagwörter:In-Circuit Testing PcbPCB Testing MethodsPcb Circuit

Circuit Board Design for In-Circuit Testers

16 Printed Circuit Board (PCB) Reliability Test Methods

An ICT works by powering up and actuating the circuitry on the PCB. The In-Circuit Test (ICT) Method. GM/LTS pcb testing consists of various tests and processes. Determining the limits of PCB reliability is all about pinpointing failures, as well as how they arise in the device.PCB assembly testing methods are an integral part of the manufacturing process.Schlagwörter:In-Circuit Testing PcbPcb CircuitIct Test For PcbSchlagwörter:PCB Testing MethodsIct Test For Pcb PCB assembly testing methods are an integral .Schlagwörter:Pcb CircuitPCB TestingcomHow To Test a PCBA (Printed Circuit Board Assembly) – .

Sometimes a test fixture .Measure the resulting expansion at 250° C to determine if the board passes the test.Once you create your testpoints, there are several techniques that can be used in your schematic level to enable in-circuit testing and ensure reliability of the .Schlagwörter:In-Circuit Testing PcbPcb Circuit

PCB Testing Methods: A Complete Guide

For instance, burn-in testing is not suitable for every .

- Stellenausschreibung Jku , JKU Jobs

- Quais As Características Do Racionalismo?

- Jes Stuttgart Konzerte 2024 – Konzerte in Stuttgart

- Easy Dimer Pudding : Easy Chocolate Pudding in the Microwave (10 Minutes!)

- Vrs : Infos Rund Um Die Haltestelle

- Freundschaft Unter Männern Synonym

- Mathe Lernzielkontrolle 3 Klasse

- Bladder Cancer Survival Rate And Prognosis

- Sam Harris: Death : Sam Harris

- Where To Stay In Athens? Best Districts Hotels

- Die Zehn Besten Rttf-Karten In Fifa 20

- Online Police Auction Sites Guide

- What Is The Ideal Weight For 180 Cm Female?