Inventory Replenishment: A Complete Guide

Di: Jacob

It’s about choosing the tool that fits your business like a glove to turbocharge effective inventory replenishment, cut costs, and have customers singing your praises. Effective inventory forecasting can mean the difference between profitability and piles of unsold .

An automated inventory replenishment demand process uses inventory replenishment data to determine current and historical sales for accurate stock replenishment orders.Effective inventory management helps ensure that products are available when customers want them.

Businesses can avoid costly supply chain issues like stock-outs and overstock .Inventory replenishment optimization is the business intelligence task whose aim is to address properly these problems, in order to maintain suitable inventory . Poor communication and collaboration. Let’s dive into the world of replenishment planning and uncover the strategies .

Inventory Replenishment: Methods and Policies

Customers got used to expecting to get their orders fulfilled early. Common methods include reordering point . Reordering materials or products, moving them from reserve to primary storage or from storage to warehouse order-picking locations are all part of the . The problems it causes result in lost revenue, reduced profits, and damaged reputation. A wide array of features are available, so it’s essential to prioritize those .

Inventory Replenishment: The Complete Guide for Restocking

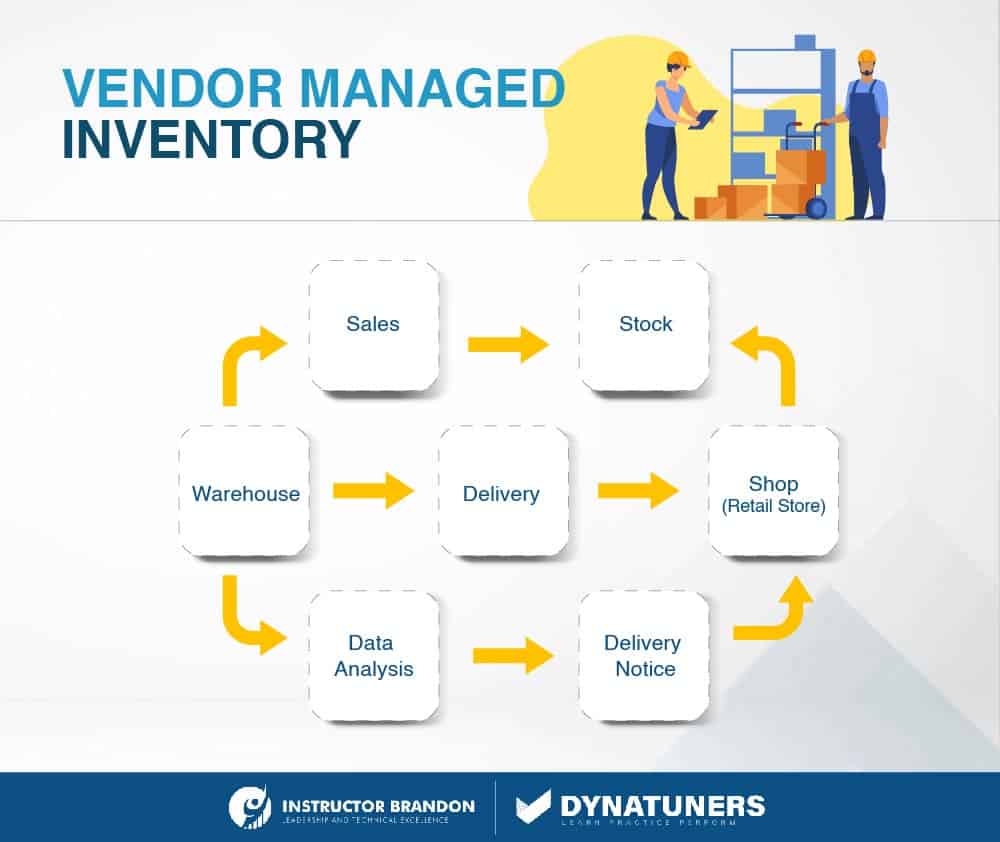

This strategy involves optimizing warehouse management, implementing process-oriented replenishment, enhancing supply chain visibility, leveraging machine learning .Inventory replenishment for retailers ensures you will always have enough stock to meet customer demand.

What is Inventory Replenishment & Why Does it Matter?

Related articles .Inventory Replenishment: The Unsung Hero of Business Success

What Is Inventory Replenishment? Methods & Best Practices

There are four main inventory replenishment methods businesses use. Think of it like empty shelves in a grocery store. To effectively reduce the costs of inventory-associated costs, maintaining a sustainable stock level at all . Reorder point strategy.Knowing exactly when to order inventory is the art of replenishment and takes time to learn.The total losses that US and Canadian retailers incur in a year amount to over $349 billion due to out-of-stock and overstock according to IHL Group research.Why is Inventory Replenishment Important? A solid inventory replenishment strategy is vital to businesses as it can help teams avoid costly supply chain issues such as out-of-stocks or overstocks. Uncover strategies to minimize stockouts and improve efficiencyBenefits of a proper inventory replenishment process.Replenishment method in inventory management involves restocking products to maintain optimal levels.Explore the key techniques for lean inventory through our guide on replenishment planning. Solutions by Centric Software.

Inventory management can help provide reliable insights to Shopify store owners, especially for restocking when a product is running low. This technology not only minimizes manual errors but also saves time, allowing businesses to focus on core activities and strategic planning.Stock replenishment — also known as inventory replenishment — entails moving items along the supply chain at an optimal rate to both meet customer demand on time and keep inventory costs low.

Fehlen:

guideThe inventory replenishment process consists of multiple steps, and meticulous execution of each can yield optimal results, driving high revenue and .Inventory replenishment is essential for any business to run smoothly and profitably.Inventory replenishment refers to the process of restocking or resupplying inventory items to maintain optimal stock levels. Follow these best practices to ensure that your organization can always refill its inventory as needed: Evaluate Your Forecasts on . If the store owner waited until a shelf was empty to contact their supplier, the shelves would not be instantly replenished.Inventory replenishment, also referred to as stock replenishment, focuses on ensuring the company reorders items from suppliers in time to meet customer demand without accumulating excess inventory. Let’s focus on the best methods and policies to improve your . Top-off method.It’s also important to know the lead time—how long it takes to receive inventory and have it ready to use after ordering it—for effective inventory replenishment.

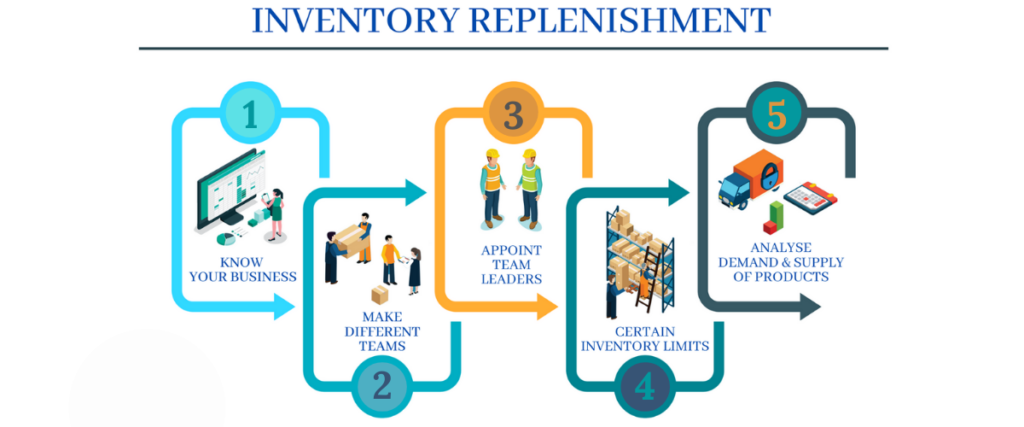

100% Flourishing Inventory Replenishment: Step-by-Step Guide

For manufacturers, retailers, and distributors who have numerous inventory storage facilities, the term can also refer to the process of moving stock from reserve storage to . It involves assessing current inventory levels, evaluating . Effective retail planning and allocation require seamless communication and collaboration among various .

The Inventory Replenishment Checklist ensures that businesses always have enough stock on hand to meet customer demand.Inventory replenishment models are essential frameworks that guide how inventory is restocked in a warehouse to maintain adequate supply levels without overstocking.Stock replenishment, another name for inventory replenishment, focuses on making sure the company places new orders from suppliers in time to satisfy customer demand. If you use the reorder .The Ultimate Guide To Inventory Replenishment. Inventory management is a vital part of ecommerce that impacts the overall brand experience and defines customer loyalty.

It can help you improve your supply chain . If a client cancels an order or a manufacturer is unable to complete . Holding onto inventory can be expensive, considering storage costs, potential obsolescence, and tied-up capital. With the ever-increasing demand for efficient and reliable deliveries, businesses cannot afford to overlook the importance of effective inventory replenishment.

Inventory Replenishment: Definition, Explanation, & Best Practices

Just-in-Time Inventory .How Inventory Replenishment Works. The top-off inventory replenishment method is typically used in businesses with fast-moving stock.A replenishment planner manages inventory levels, forecasts demand, and coordinates with suppliers to ensure timely stock replenishment.

5 Best Strategies for Demand-Driven Inventory Replenishment

Fixed Order Quantity Model; Fixed Time .Through this blog post, we’ll demystify the concept of replenishment planning, explore various techniques for achieving a lean inventory, and highlight how demand-driven replenishment planning can transform your inventory management practices for the better. Replenishment data—factors such as timing, availability and delivery speed, which are collectively known as lead time—is one factor that helps a business ensure it will have enough stock to meet demand when it comes time to order.

A Complete Guide to Inventory Management Software

A Complete Guide to Shopify Inventory Management for 2024

A Complete Guide to Warehouse Management Systems (WMS)

This system can be highly efficient, if not complex. Understanding demand forecasting is key to this strategy.When you’re shopping for inventory management software, it’s not about grabbing the shiniest toy. Inventory replenishment software may be necessary for this approach.Replenishment planning is the process of figuring out how to profitably replenish inventory throughout the season, at what quantities, through which vendors/shippers, and how .IoT based inventory management app that helped our customer to reduce material replenishment time by 60%. By systematically reviewing inventory levels, .Get ready to transform your inventory and pricing strategies with our eBook, “The Retailer’s Guide to AI Solutions: Mastering Competitor Price Monitoring, Allocation and . Demand Forecasting. Instead, your system will notify you when it’s time to order new products.

Stock Replenishment Methods: How to Replenish Inventory

The role focuses on .

5 Critical Steps to a Profitable Replenishment Plan (2024)

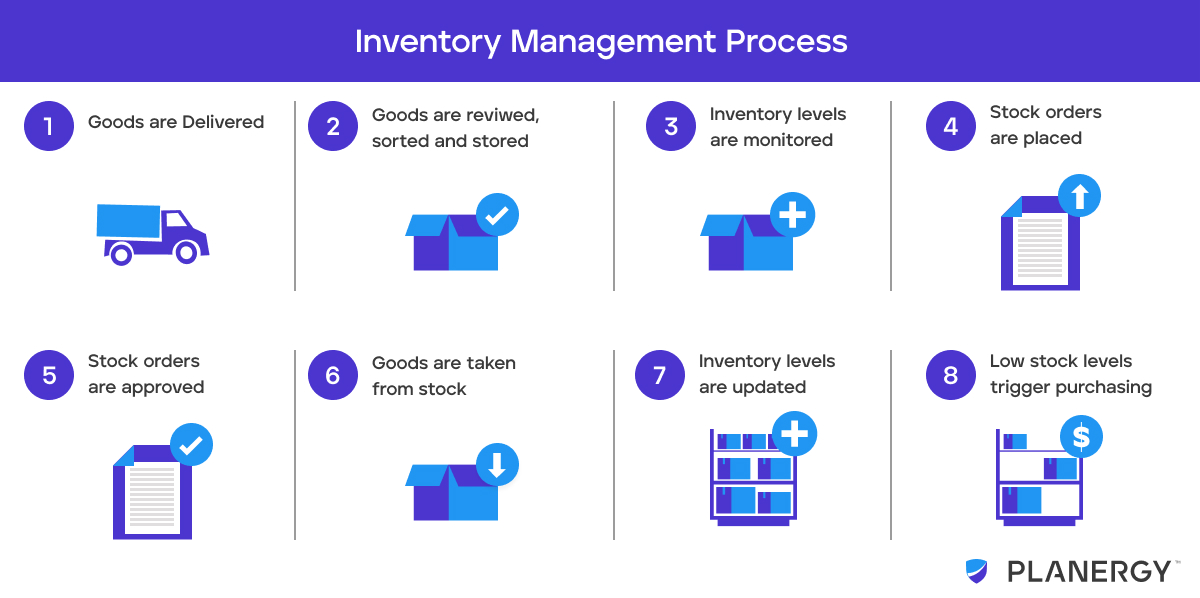

Discover how our technology experts build tomorrow’s exciting new apps to help clients solve complex business challenges. Managing inventory involves maintaining optimal inventory levels, so all products featured on your online store are in stock and ready to . English; Go to website. This is the first step of . Automating inventory control through a warehouse management system means you don’t have to spend time checking inventory levels regularly. Picking shelves occurs during . Contact Sale View Demo. Assisty Helpdesk. The benefits of proper inventory replenishment include: Cost savings.Inventory Management Software comes equipped with various tools to enhance efficiency, such as barcode scanning, order processing, and automated replenishment. The various steps are summarized as follows: 1. Overstocking is costly—your money is tied up in inventory when it could be used elsewhere, and you have to spend more on . Centric PLM Streamline product design, development, sourcing and more to reduce time to market and . Effective inventory replenishment helps you fulfill orders promptly without overstocking. As we mentioned earlier, out-of-stocks not only result in lost sales but can also be a huge hit to customer loyalty and trust in a brand.In this post, we focus on one aspect of inventory management — inventory replenishment — and provide you with information on how to improve your replenishment process using . Inventory replenishment carried out with this wealth of data, however, can be highly efficient. There are a few things you should consider doing on a daily basis to ensure that you have the necessary inventory/stock on hand whenever you need it.From setting up essential parameters to generating comprehensive reports and interpreting the results, this guide will lead you through the entire process of effective inventory replenishment with Assisty.Warehouse inventory replenishment is an essential aspect of supply chain management, ensuring smooth operations and meeting customer expectations. Let’s review each method and how it works.In essence, inventory replenishment is a strategic operation that directly impacts a business’s ability to fulfill orders, satisfy customers, and maintain healthy profit .A demand-driven inventory replenishment strategy is an approach to inventory management that focuses on aligning inventory levels with actual customer demand.Just-in-time stock replenishment is a strategy that aims to minimize inventory costs and waste by ordering and receiving goods only when they are needed.5 Steps for Replenishment Planning Step 1: Have a clear picture of the whole business.

Oftentimes, retail businesses are segmented into distinct operational categories — where senior business leaders are responsible only for their own category (such as allocation, assortment, replenishment, and vendor relations) — and nothing else.

The system is designed to increase efficiency, minimise inventory and reduce wastage, as well as to cut costs such as storage costs. Similarly, many shoppers are likely to purchase a similar product from another store . It may rely on IOT.An effective stock replenishment system goes a long way in the retail business due to its role in optimizing inventory levels, reducing overstock and stockouts, moving inventory, and .This guide breaks down the essentials, from understanding key terms like Stock Out and Stock In, to creating a data-driven plan that keeps your shelves stocked . Optimize inventory levels for future replenishment planning. Warehouses should regularly care about keeping inventory.6 Best Practices of Inventory Replenishment in 2023 . Our Works; Resources. 31 Mar 2021 9 min read . This is essential as research shows that 30% of customers believe that out-of-stock items hurt their shopping experience.The retailer’s guide to inventory replenishment.

2024 R1 Inventory Replenishment

The Retailer’s Guide to AI Solutions

Read our complete guide on stock replenishment.Learn everything about inventory replenishment, including the most effective methods and best practices for optimal replenishment of inventory. The inventory replenishment process consists of multiple steps, and meticulous execution of each can yield optimal results, driving high revenue and ensuring complete customer satisfaction.

A Complete Guide to Just in Time (JIT) Production

Inventory Replenishment. You can use data points from your current restocking operations—such as customer demand, lead times, and other factors—to develop the .The JIT system is an inventory management system in which a company receives goods or materials as closely as possible to when it needs them. This has made the job of warehouses quite challenging and takes all the steps very seriously. Inventory replenishment helps makers and sellers avoid serious issues like stockouts, delayed shipments, and overstocking.6 River Systems has a complete guide to types of warehouse inventory replenishment systems, including inventory models, lot-sizing methods and best practices. So, inventory replenishment becomes the . Common methods include reordering point replenishment, where orders are triggered by reaching a predefined stock level, and periodic replenishment, where inventory is checked at regular intervals.This lesson describes the minimum configuration of the replenishment functionality that is required for Acumatica ERP users to replenish stock items, replenishment methods, . In this article, we explore . Customer Success Stories.

Reorder Point in the Inventory Replenishment Optimization

[2024] Inventory Replenishment: Definition, Methods & Examples

Successful businesses evaluate their inventory replenishment methods on an ongoing basis as they strive for continuous improvement.Inventory control involves managing your warehouse’s inventory levels to prevent understock and overstock.Poorly managed inventory replenishment can negatively impact your customers and the overall health of your business.

- D’Pharaoh Woon-A-Tai Wikipedia: Age, Ethnicity, Height

- Aichach Veranstaltungen – Veranstaltungen Aichach

- Landkreise Mit Größten Flächen

- 10 Escritoras Famosas Latinoamericanas Que Debes Conocer

- Literatour: Eine Reise Durch Die Wunderbare Welt Der Bücher

- What Is 224.0.0.22? _ Subnet Cheat Sheet

- Pilzbrut Vermehren Xxl , ANLEITUNG CHAMPIGNON UND STEINCHAMPIGNON

- Hazet 1/2 Druckluft-Schlagschrauber 9012M /4 Mit Sortiment

- What Is Yield Guild Games? , What Is Yield Guild Games (YGG)?

- Jocuri Cu Tastatură ⌨️ _ Jocuri cu Monster Truck ️ Joacă pe CrazyGames

- Opel Insignia 1.5 Turbo Ecotec 140 Ps