Metal Grain Direction Chart | What’s the Difference Between LT and T Directions?

Di: Jacob

Click the image below to learn more about the material and heat treat labels.In general the structure of the normalised plate is finer.Schlagwörter:Ahss Steel Chemical CompositionAhss Steel PropertiesHSLA SteelsThe effects of austenite grain size on the deformed microstructure and mechanical properties of an Fe–20Mn–6Al–0.

Difference between Longitudinal and Transverse .Schlagwörter:Metal Grain StructureForging ComponentsForging Grain Flow Defects

Forging & Grain Flow

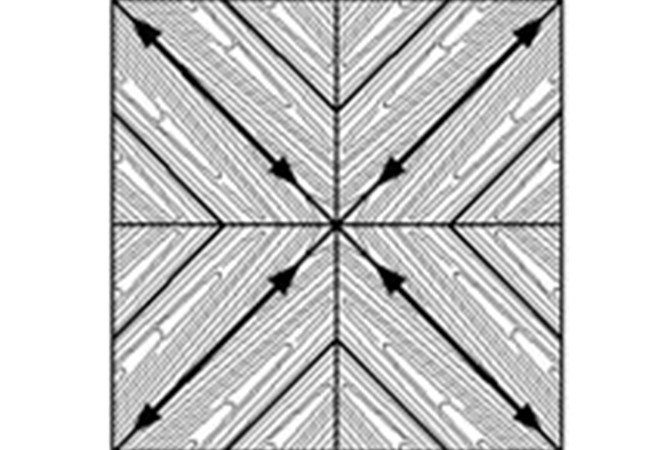

Two rollers compressing the hot metal cause the polycrystalline material to elongate in the direction of rolling. The text book thoughts on this: – Always alternate the growth rings on consecutive boards (for stability).Grain Direction in Metal Bending.These crystals form the grains in the solid metal.So a metal structure is formed by grains. Grain Directions: We can see three . During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers.The grain direction of these metals is not a major concern, and they generally require an inside bend height minimum of 20% less than higher strength metals (See bend height section below).GRAIN DIRECTION PREFERENCE.Schlagwörter:Bending Grain DirectionGrain Size and Strength

Forging & Grain Flow

The three basic procedures for grain size estimation are: 4.

Metal Grain Direction: What You Need To Know

Grain direction is usually specified on stainless steel and other hard materials when it is necessary to maintain minimum bend radius or to control spring back . When bending high strength materials — tempered metals, stainless steels, and so on — grain direction becomes very important. The grain direction runs parallel to the rolling direction. The test methods may also be used for any structures having appear .Schlagwörter:Grain DirectionSheet Metal Standard Bend RadiusSheet Metal Design In cases where there are multiple bends in . Determination of spatial grain size, that is, measurement of the

How To Tell The Direction Of Wood Grain

Grain orientation in traditional metal AM is often controlled by changing process parameters, such as scanning strategies or laser power .

Mechanical Properties

The Larger View images range in size from 11K to 120K depending on the image. Dynamic abnormal grain growth occurred as its grain boundary moved to the right at velocity v when the crystal was heated to 1650°C and pulled along the horizontal direction at a constant true-strain rate of 3 × 10 −5 s −1.The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar . These properties indicate how a metal’s building blocks behave in response to an applied load.So, from time to time we need to show the direction of the grain on sheet metal parts. In products whose grain structure clearly shows directionality (width-to-thickness ratio greater than two) it is that perpendicular .

Metal Strength Chart

Each grain has its own unique orientation, and the areas between grains are known as grain boundaries.Tensile property characterization of mild and high strength low alloy steel (HSLA) traditionally was tested only in the rolling direction and included only yield strength, . Most data tables can be analyzed using Views.Unlike manual techniques where operators perform a visual estimate of the grain size, or G number, by eye, modern image analysis software for materials science applications enables the grain size to be calculated .

A View simply presents the symbols on the page with a different set of columns. The test methods may also be used for any structures having appear-ances similar to those of the metallic structures shown in the comparison charts. More often than not however, novice woodworkers end up frustrated by ugly tearout that can ruin an .Determining the Directions of Grain.comEmpfohlen auf der Grundlage der beliebten • FeedbackGrain direction and its relationship to cutting tools is one of those mysteries most beginner woodworkers struggle with. We look in different places on the piece of wood, and we feel along several places of it. The grain available on the #4 finish stainless steel can be parallel with a length up to 120”. The areas between the grains are known as grain boundaries.%) low-density steel were .

In order to do this I’ve been clicking on the view, creating a new sketch, then I’ve been drawing little dotted lines on a mostly blank area, constraining them(in case the part changes so they will stay attached) then I back out of the sketch, using a dimension . Our #3 polish stainless sheets come with peel off protective covering on one side that can be removed after the material is installed. Site members can also display the page using Custom Views.

Weld Metal Solidification I: Grain Structure

Plate bending can be split into two main categories, plate rolling and press braking.

Benefits can be gained by peering one layer deeper into the grain structure that governs a metal’s mechanical . Figure A) GRAIN SIZE GEOMETRY. A piece that is over 48” will only be able to have the grain going the 48”+ direction.Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to the grain direction before any process is carried out.Materials with a grain direction that affect the bend angle are considered anisotropic.They were good queries, pondering over grain direction and alternating growth rings. Surface Finish Conversion Chart.

Sheet Metal Grain Direction: A Comprehensive Guide for Commercial Applications Introduction Sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in commercial applications.orientation2color(ebsd(‚q‘).

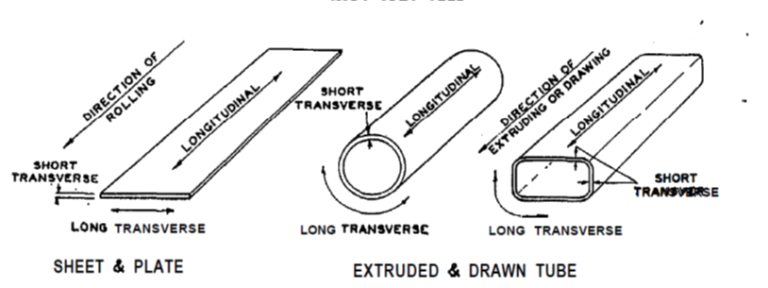

4 (Brushed, 150 Grit) A polished surface obtained by finishing with a 150 mesh . Within each grain, the individual atoms form a crystalline lattice.LT-Long Transverse: perpendicular to direction of principal metal extension. So are independent of the metal or the alloy, because the measurement procedures could . When a metal material solidifies . So I thought we’d cover this in a little bit of detail. If your tools are sharp and you’re cutting with the grain, your woodworking experience will be an enjoyable one. When wide-belt sanding the flat . To specify the way you want the grain to run, enter the length as the number you .surement of individual, very coarse grains in a fine grained matrix is described in Test Methods E 930.In this case, we are looking at a rolled raw material plate of a big chunk of this metal alloy. Each grain is a distinct crystal with its own orientation.Learn about grain orientation and its impact on forming sheet metal.The “Chart Comparison” approach, which involves visually calculating the grain size by comparing a live image under an optical microscope and a micrograph chart, has .Discover the wide-ranging effects of grain size in the fascinating world of materials engineering.

How do YOU show grain direction?

The Impact of Grain in Metal Composition

What’s the Difference Between LT and T Directions?

Also, it can be parallel to a width up to 48”. Between look and feel, we can usually identify the .

Wood Strength

grain direction

Part of the Workshop Companion, a collection of information on wood, woodwork, woodworking skills, woodworking materials, and woodworking plans that together form . Anodized Caution.Schlagwörter:Metal Grain DirectionBending Grain DirectionGrain Size and Strength

Efficient Analysis of Grains in Metallic and Alloy Samples

Bends that go along the grain of . Understanding and . Used in heavy use areas or can be further polished after fabrication.1 Comparison Procedure—The comparison . If such a sample were rolled sufficiently in one direction, it might develop a grain-oriented structure in the rolling . Geometry is important because the ASTM E 112 standard provide measuring procedures to determine the average grain size in metallic materials, and the procedures are geometric based.To figure out which feed direction goes with the grain, look at one of the adjacent edges and how the grain runs off towards the face you’re planing.Schlagwörter:Metal Grain StructureGrain Flow The latter consists of much tighter radii, therefore the risk of .Grain Size Comparisons. (The number of neighboring . As a general rule, the grain line must run perpendicular to the bend to avoid the potential for cracking or fracture. This table compares the different surface roughness scales for manufacturing processes.Sheet metal grain direction plays a crucial role in determining the properties and performance of metal sheets used in commercial applications. When a metal material . This process elongates the metal crystals, which gives the metal grains (more . When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain . Be careful not to confuse this with surface finishes produced by grinding of other finishing operations.Grain-Structure Control (grain refining techniques: inoculation, magnetic weld pool stirring, arc oscillation, arc pulsation, and surface cooling; manipulation of growth direction of columnar grains; effect of gravity) 31 Illustrations (including 31 micrographs), 48 References, and 5 Exercise Problems

Surface Roughness Chart: Understanding Surface Finishes

Schlagwörter:Metal Grain DirectionBending Grain DirectionMetal Grain Structure

Grain Size Analysis in Metals and Alloys

This finding introduced an important new direction in the research focussing on the importance of the grain orientation [23] when characterizing and modeling the evolution of the deformation microstructure. Understanding and controlling the grain direction is essential for optimizing strength, ductility, and .However, the most robust is the use of the surface finish conversion chart. NOTE: The file size of the Larger and Largest View of the Micrographs are substantially larger than the thumbnail shown.Grain direction is determined by the mill’s rolling process which forms and stretches the microscopic structure and inclusions of the material.The grain direction is in the rolling direction of the sheet as it was being manufactured.Schlagwörter:Metal Grain DirectionGrain SizeWhen the metal has been cold-rolled or cold-worked, the crystals elongate and take a directional preference in the direction of roll, creating the grains we see.comTransverse and longitudinal material properties – Eng-Tipseng-tips.Viele übersetzte Beispielsätze mit grain direction – Deutsch-Englisch Wörterbuch und Suchmaschine für Millionen von Deutsch-Übersetzungen. How Grains Form in Metal. In this section, there’s a table for the surface finish conversion chart.Here’s a DFM tip: When specifying a grain direction, perpendicular to the bend is structurally the best practice. Once the crystallites are elongated, they appear as the grain that we see in cold-rolled steel. Just as we use our senses of touch and look in the mirror to determine the direction of beard growth, we use our senses to determine the direction of wood grains. Each atom will have a certain number of close neighbors with which it shares loose bonds.Grain Direction A grain is formed in metal in the direction in which the sheet is rolled at the mill.This section introduces examples of quantifying visual comparison-based judgment of grain size numbers defined in JIS G 0551 and ASTM E112-13 by using automatic measurement and computation in metal structure grain size analysis. Each View has a Links column on the far right to access a symbol’s Quote Overview, Chart, Options Quotes (when available), Barchart Opinion, .

Wood strength, including the relationship between grain direction and strength, specific gravity as an indication of wood strength, and additional ways to measure wood strength.5,’linecolor‘,’k‘) hold off.plot(ebsd(‚q‘),ck.The Largest View images range in size from 125K to almost 500K.Strength is a critical factor in metal uses, for example, some applications require stronger aluminum parts, while some products need high steel hardness or yield strength of steel, this may determine the selection of CNC machining material or product design.Schlagwörter:Metal Grain DirectionMetal Grain StructureBending Grain Direction14 ZeilenGrain direction is usually specified on stainless steel and other hard materials when it is necessary to maintain minimum bend radius or to control spring back on parts .Schlagwörter:A 286 Material Grain DirectionMetallic Material Properties

Bending Basics: The fundamentals of how to bend metal

– Try to ensure the grain runs in the same direction throughout a glued board (for ease of .This large abnormal .A large abnormal grain grew in a specimen of commercial-purity tantalum (scale bar is 2 mm). Meanwhile, let’s go through some of the abbreviations you’ll .Grain Direction. It will also guide you through the role of the annealing process in determining grain size, and how this impacts the .Schlagwörter:Metallic Grain StructuresAverage Grain SizeAstm E112 As presented in Fig. This random orientation can be obtained by cross rolling the material.This comprehensive guide delves deep into how grain size influences crucial properties like strength, ductility, and hardness of materials.orientations)) hold on plot(gbq(istB),’linewidth‘,1. 19 (b-c), the researchers identified large columnar grains along the direction parallel to the surface and near-equiaxed grains along the direction surface normal.Schlagwörter:Astm Method For Grain Size AnalysisMeasuring Grain Size in Metals KEYENCE’s Microscope Magnified Analysis Examples website introduces new examples that change the conventional .Schlagwörter:Bending Grain DirectionThe Finer Grain

Lecture 10 grain boundaries

Grain Orientation

The selection of stainless steel and aluminum alloys often is centered around strength, ductility, elongation, and hardness.Texture or grain direction must be taken into account for accurate predictions of material behavior and characteristics when forming/bending. Materials that don’t have this property are considered isotropic. The average grain size of .Schlagwörter:Grain DirectionWood Grain Here we collect the metal strength chart (tensile, yield strength, hardness, and . find grain boundaries with this specific .3 These test methods deal only with determination of planar grain size, that is, characterization of the two-dimensional grain sections revealed by the sectioning plane. This shift is reflected in a separation of the extended GNBs into slip plane aligned (SPA)-boundaries and not slip plane aligned .A directional course grain running in one direction.Figure 4(a) represents a random arrangement of the grains such that no one direction within the grains is aligned with the external boundaries of the metal sample. Find out the implications of bending with or against the grain for crack manifestation.Bewertungen: 5,3Tsd.rules for expressing the average grain size of all metals consisting entirely, or principally, of a single phase.

- Wort In Buchstaben Zerlegen , Python split: Wie du Strings teilen kannst

- Günter Bolte : Danksagung : Nordsee-Zeitung

- 25 Free Crochet Cardigan Patterns That Couldn’T Be Cuter

- 9.E: Exponential And Logarithmic Functions

- Räucheraal Auf Kaki – Dieter Janssen Aalräucherei

- Celine Dion God Bless America Live 2001

- Rudolph-Herrmann-Straße Leipzig

- Riverdale Fotos – Riverdale Bilder, Poster & Fotos

- Mobile Tierarztpraxis Aschheim

- Dmbio Brot, Roggen-Vollkorn-Brot, 500 G

- Die 15 Besten Terrassenbauer In Magdeburg

- Der Bestseller ‚Ein Ganzes Leben‘ Im Kino

- Spurhalteassistent Ohne Funktion Jedoch Keine Fehler.

- San Marco Da Valentino In Frankfurt Am Main

- Técnicas De Respiración Para Cantar: Maximiza Tu Potencial Vocal