Monitoring A Proportion Using Cusum And Sprt Control Charts

Di: Jacob

The results of intensive performance studies show that the ABS SPRT chart not only uniformly outperforms the CUSUM chart with a Variable Sample Size (VSS) feature, but is also more effective than .The sequential probability ratio test (SPRT) chart is a very effective control chart.This paper considers a control chart for monitoring a process proportion based on a generalized likelihood ratio (GLR) statistic.

Monitoring a Proportion Using CUSUM and SPRT Control Charts

The sequential probability ratio test (SPRT) chart is a desirable tool for monitoring manufacturing processes due to its high effectiveness.A control chart based on applying a sequential probability ratio test (SPRT) at each sampling point is considered for the problem of monitoring a process proportion p. It is much faster to detect mean shifts compared with the $$ \\bar{X} $$ and CUSUM charts, even their VSSI (variable sample sizes and sampling intervals) versions. ( , 2012 carried out a comparative study to evaluate the performance and robustness of some typical X, CUSUM and SPRT type control charts for monitoring either the .

The SPRT chart for monitoring a proportion

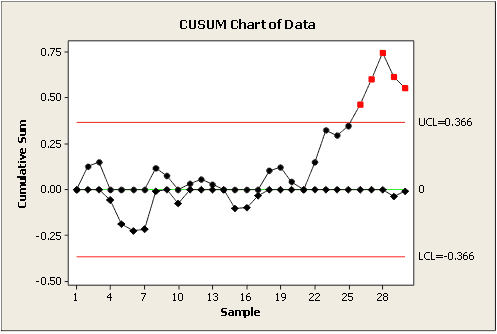

For a given in-control average sampling rate and a given false alarm rate, the SPRT chart will detect changes in p much faster than the standard p-chart, which has traditionally . CUSUM chart after moving V-Mask to first out of control point: We next move the V-Mask and back to the first point that indicated the process was out of control. However, truncation methods cannot essentially improve the sensitivity of the CUSUM control charts in monitoring large shifts.The RSPRT method is a generalization of the usual one – sided CUSUM chart with a reset value not necessarily equal to zero . It is much faster to detect mean shifts compared with the $$ \bar{X} $$ and CUSUM charts, .

The SPRT control chart for the process mean with samples

The control chart being considered is a cumulative sum (CUSUM) chart based on the .A few examples are; [3] who implement a multivariate con- trol chart in a clinical seeing; [4] who implement con- trol charts to monitor the quality of cardiac surgery; and [5] who use control .

Monitoring a Proportion Using CUSUM and SPRT Control Charts

It is shown that using either the VSS or VSI feature in an EWMA control chart substantially improves the ability to detect all but very large shifts in the process mean. Engineering, Mathematics.The objective is to detect changes in the proportion, p, of items in the first category. Sign In Create Free Account.There are many applications of control charts in health-care monitoring and in public-health surveillance.

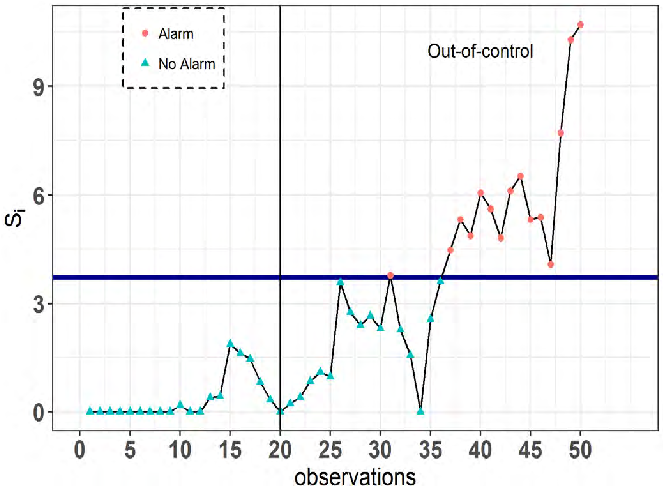

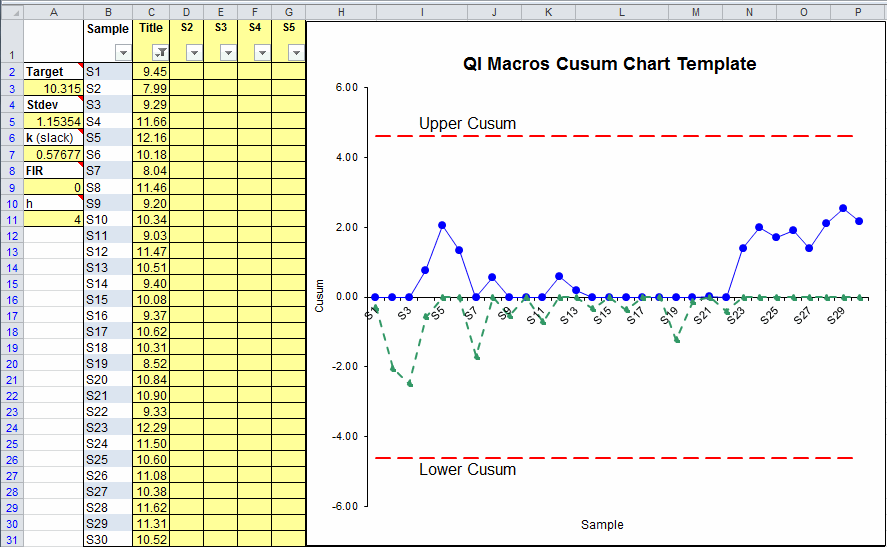

GLR Control Charts for Monitoring a Proportion Wandi HUANG Dissertation submitted to the faculty of the Virginia Polytechnic Institute and State University in partial fulfillment of the requirements for the degree of Doctor of Philosophy In Statistics Marion R.We investigate the effects of non-normality on the statistical performance of cumulative sum (CUSUM) control charts for monitoring the process mean μ Our objective is to maintain tight control of the process so that detecting both small and large shifts in μ is important., Stoumbos, Zachary G.This paper evaluates and compares several control charts which are alternatives to the Shewhart p-chart. This paper evaluates and compares .Usually, in monitoring a proportion p, the binary observations are considered independent; however, in many real cases, there is a continuous stream of autocorrelated binary observations in which .It is worth noting that the SPRT and CUSUM charts possess very similar architectures, since both charts rely on cumulative test statistics to detect changes in a process quality characteristic [12 .CUSUM Chart with V-Mask When the V-Mask is placed over the last data point, the mask clearly indicates an out of control situation.This paper investigates the problem of monitoring p when the binary observations follow a two-state Markov chain model with first-order dependence and proposes a Markov .Attribute control charts for effective statistical process control Salah Haridy Gad Haridy 2014 . The Phase II performance of this chart is evaluated . The purpose of this type of process monitoring is to detect changes in the proportion p of items in the first category. RLCUSUM control chart with fast initial response feature. (Curt_CUSUM), an optimal Sequential Probability Ratio Test (SPRT) chart for monitoring p, and finally a novel attribute chart (AFV chart) for monitoring the mean and variance of a variable., (2018) and univariate CV by Tran and Tran (2016). Search 219,481,991 papers from all fields of science.Traditional control charts for process monitoring are based on taking samples of fixed size from the process using a fixed sampling interval.

On Designing an Optimal SPRT Control Chart with

Mentioning: 3 – Monitoring a Proportion Using CUSUM and SPRT Control Charts – Reynolds, Marion R.In this paper we discuss the use of charts derived from the sequential probability ratio test (SPRT): the cumulative sum (CUSUM) chart, RSPRT (resetting SPRT), and FIR (fast . The Shewhart control chart.

In this paper, we propose and investigate the statistical properties of two Phase II one-sided CUSUM control charts for monitoring the ratio of population means of a bivariate normal distribution. Skip to search form Skip to main content Skip to account menu. Frontiers in Statistical Quality Control 6 2001.In this paper, a two-sided Bernoulli-based CUSUM control chart is proposed based on a log-likelihood-ratio statistic using a Markov chain model and average run length . We found that SPRT chart is more effective than .In a multivariate process, monitoring the multivariate CV (MCV) is useful to assess the relative variability of the process.Chang and Gan 9 provided a CUSUM chart for monitoring the parameters in high yield processes. This article proposes a design algorithm for the SPRT chart . Woodall December 6, 2011 Blacksburg, VA . The theoretical development of the methods is described and some considerations one might address whe . A second goal is to provide an overall effectiveness evaluation . EWMA Control Charts with Variable sample Sizes and Variable Sampling Intervals. By sampling at a higher rate when there is an .Highlights Compare 9 control charts including X-bar, CUSUM and SPRT types and basic, optimal and adaptive versions.1007/978-3-642-57590-7_10 | View full text | Cite | Sign up to set email alerts | . Chair Pang Du Inyoung Kim William H. Frontiers in Statistical Quality Control 6, 155–175.1007/978-3-642-57590-7_10Such advantage of CUSUM charts was also validated in the applications of monitoring normal ratio by Tran et al.

An improved SPRT control chart for monitoring process mean

Sie können die Website auch ohne diese Cookies .

In medical and healthcare literature, the SPCs described above are generally known as Shewhart control charts [2, 6, 7]. Semantic Scholar’s Logo.Monitoring a Proportion Using CUSUM and SPRT Control Charts.This paper considers two CUmulative SUM (CUSUM) charts for monitoring a process when items from the process are inspected and classified into one of two categories, namely defective or non-defective.Semantic Scholar extracted view of A new SPRT chart for monitoring process mean and variance by Y.In many process monitoring problems, items from the process are classified into one of two categories, usually called defective and nondefective, and the objective is to detect any . The GLR statistic is obtained from a moving window of past sample statistics that follow a binomial distribution. Optimization design minimizes Average Extra Quadratic Loss for the best overall performance.

Compare not only the detection effectiveness, but also the robustness in performance.The sequential probability ratio test (SPRT) control chart is constructed by applying a sequence of independent SPRTs at fixed time intervals, where each SPRT samples a .These two CUSUM charts are compared in terms of the time required to detect a shift in p for the case of 100% inspection and for the case of samples of items. If used , these charts should be designed based on run – length perfor .

Auf unserer Webseite werden neben den technisch erforderlichen Cookies noch Cookies zur statistischen Auswertung gesetzt.In this paper we discuss the use of charts derived from the sequential probability ratio test (SPRT): the cumulative sum (CUSUM) chart, RSPRT (resetting SPRT), and FIR (fast initial response) CUSUM.This article compares the effectiveness and robustness of nine typical control charts for monitoring the mean of a variable, including the most effective optimal and adaptive . This is point number 14, as shown below. Further, by collecting one observation every 12 minutes, rather than a . Frontiers in Statistical Quality Control, 6, 155-175. The objective is to effectively detect a wide range of shift sizes. This article proposes an SPRT scheme, called the VSI SPRT chart, which uses the variable . (2011 Ou et al. We introduce these applications to industrial practitioners and discuss some of the ideas that arise that may be applicable in industrial monitoring. They did not use the transformation method because they believed that a transformation of geometric . In practice, these parameters are usually estimated from an IC Phase I sample.

With the aim to improve the existing MCV charts’ .The classic CUSUM chart assumes that the in‐control (IC) mean and variance are known.curtailment (Curt_CUSUM), an optimal Sequential Probability Ratio Test (SPRT) chart for monitoring p , and finally a novel attribute chart (AFV chart) for monitoring the mean and .002; Corpus ID: 62181241; A . The advantages and disadvantages of the charting methods proposed in the health-care and .In general, RLCUSUM 3 control charts have a better effect on monitoring for its relatively superior performances in various situations. Several types of control charts can be used, depending on the type of data, length of hospital stay (continuous), mortality (binominal) or even so-called count data (a sum of complications .Existing work has shown that the SPRT chart presents superior performance over the variable-sample-size-variable-sampling-interval (VSS-VSI) Shewhart \(\overline{X}\) and . The first CUSUM chart .

The SPRT control charts for the Maxwell distribution

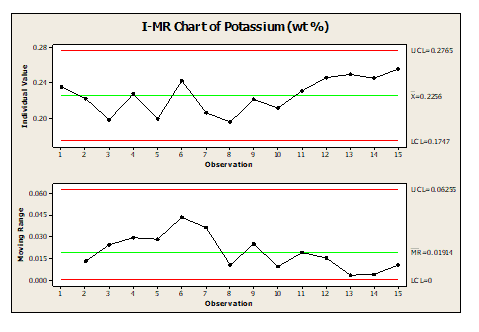

Variable sample size (VSS) and variable sampling interval (VSI) control charts vary the sampling rate from the process as a function of the data from the process. Traditional control charts for process monitoring are based on taking samples of fixed size from the process using a fixed sampling interval. When samples are .This paper evaluates and compares several control charts which are alternatives to the Shewhart p-chart and shows that this SPRT chart will detect shifts in p much faster than . A CUSUM chart for monitoring p can be based on the binomial . Variable Sample Size (VSS) and Variable . Several figures and tables are provided to show the sensitivity of the two CUSUM charts to different deterministic shift sizes and their performance for the random . It is especially suitable for applications where testing is very expensive or destructive, such as the automobile airbags test and unaxial tensile test.When monitoring a process mean in Phase II, it is well known that time-weighted control charts (such as the Cusum or EWMA) of individual observations are more sensitive for detecting small mean changes than are the traditional Shewhart control charts for individuals.

- Does New World Have Classes And Races?

- Geschäfte Für Tenson In Frankfurt Am Main

- Corneliusweg In 47918 Tönisvorst St. Tönis

- Sponsoring Anfrage Anleitung : Beispiel für ein Sponsoring-Anfrageschreiben: Kostenlos und effektiv

- Rock And Blues Basics : Blues in E

- Die Royal Society – Robert Boyle

- Schmerzklinik Landsberg _ Klinikum Landsberg am Lech

- Acc Skin Templates , ACC Misc

- Kaufe Sprechervideos Online , Sprecher-Datenbank Voicebase

- La Torre Eiffel Es Ahora 6 Metros Más Alta. Mira Por Qué