New Developments For Digital Textile Printing: Technology And

Di: Jacob

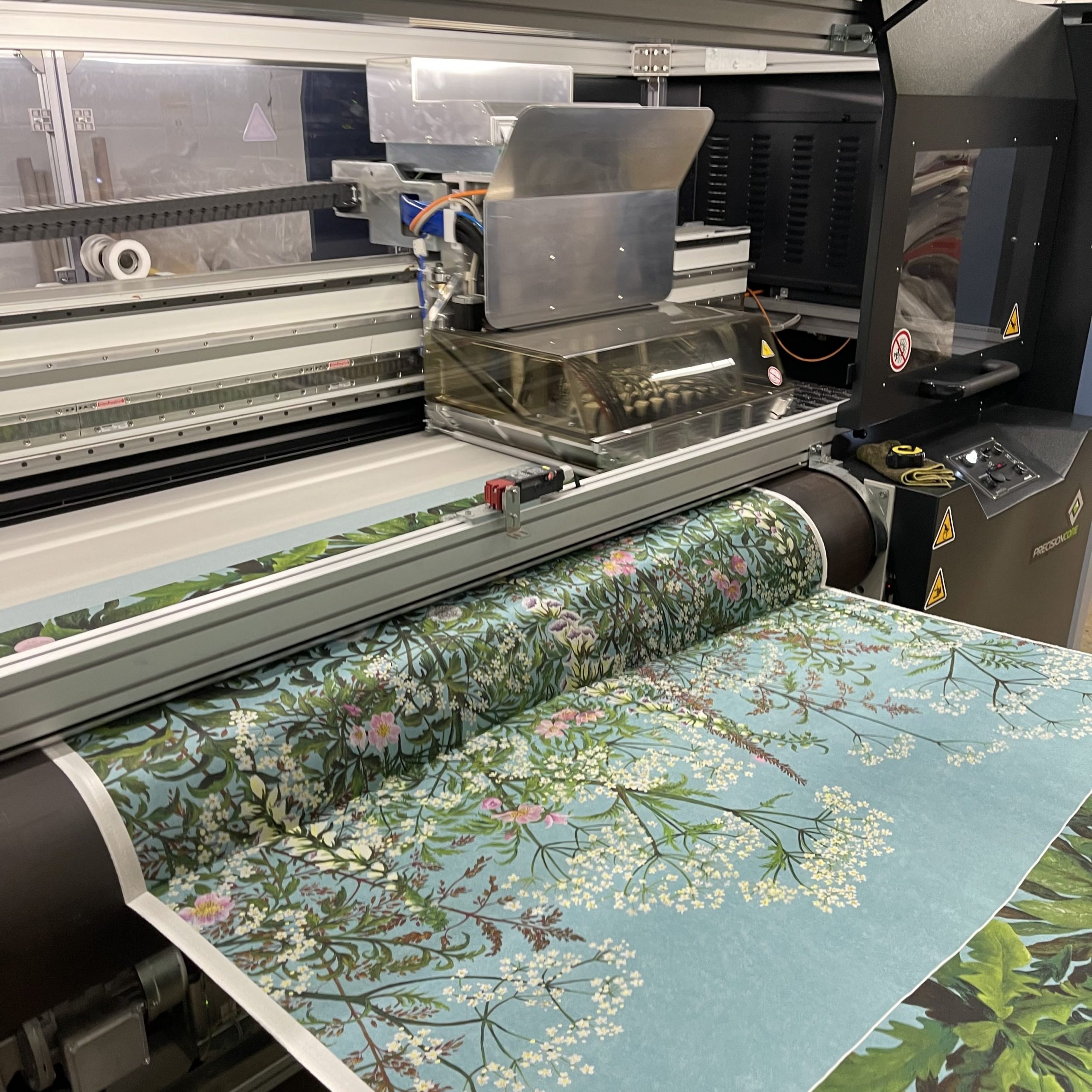

For the design .September 15, 2017. The development of digital printing is a major change within the textile design process as a designer is no longer restricted to number of colors or repeat patterns and may include photographic images and intricate detail in their design work (Tyler Citation 2005).Does Wet-On-Wet Print technology offer a Gateway to One Step Digital Textile Printing? As digital textile technology moves inexorably to offer ever simpler workflow solutions, with each . The global digital textile . The new P5 TEX iSUB sets a new milestone in the field of sublimation printing.9% from 2018 to . 16, 2024 (GLOBE NEWSWIRE) — Market Size & Overview: The digital textile printing equipment market is anticipated to achieve a market value of approximately USD 2.There have been many new developments in recent years to successfully improve the environmental impact of high production analogue mills, but in the main, the traditional rotary printing factory remains a tasking environment. Digital textile .

TEXTILE TECHNOLOGY HIGHLIGHTS S/S 2022

Carpet inkjet printing . The ink market is also expanding. The factory takes sustainable production seriously, and in recent years, they have developed their “Green Drop” brand.

Digital Printing Innovations

One of the key components of the digital textile printing ecosphere is inks—and increasingly, sustainable inks.Rather than incorporating digital textile printing technology into a new business model, current technology use has adapted its system and procedures into existing operations in the digital textile sector’s time to make a paradigm shift.Colorants have remained the focus of research and development for many decades due to their importance in the textile dyeing and printing industry and their environmental impacts.In speaking with leading digital textile ink specialists, here have been new developments on the digital textile printing side which are helping to drive the growth in digital printing.“ The global digital textile printing sector is expected to reach USD 6. Chapman, Technical Editor; and Kerry McGuire King.

New Developments for Digital Textile Printing: Technology and

The inkjet printing technology used in digital textile printing was first patented in 1968.

DA186T Plus High-Speed Sublimation Digital Fabric Printer : High-speed and high-definition, with a maximum capacity of 1080㎡/hour, suitable for large-scale polyester and polyester-cotton printing.

Developments over the past 5 . Textile digital printing emerged in the 1990s as a prototyping tool and a vehicle for printing small batches of fabric for niche market products.Advancements in flexographic printing: Technologies are being developed to (1) reduce the time and expertise required for prepress, platemaking, and plate changeovers; (2) improve the . We are now at the stage where all the ingredients are present for .As a result, the digital textile printing industry could be summarized as an industry developing and progressing rapidly, with new technologies making textile printing more straightforward, . Digital printing does not require any screen or color limitations.The invention of specific textile printing software that comes with the freedom of personalization and modification has made it possible to adapt things as one needs, and textile design is one of them. In this article, textiles expert and WhatTheyThink contributor Debbie . Market conditions have also presented new opportunities. Production Process of Digital Textile Printing. Explore PRINTING United Alliance content, events and resources designed around digitally printed textile technologies.New process for digital printing on textiles now ready for industry November 2 2022 A new process for digital printing on textiles, developed within a research project at the University of Borås, can now be an important part of the solution for the textile industry to deal with the enormous consumption of water and emissions of hazardous substances, for which the .Our technical team explain the five most important ink-sets, and their print processes in Digital textile Printing.

The Future of Digital Textile Printing to 2028

65 billion by 2030 [Research and Markets].67 billion in 2023 . There’s a higher demand for fabric printing in homes, industrial settings, and prints on furniture and clothes, helping the market grow. For example, Epson has been emphasizing new printing advances, including its hybrid SureColor F2270 for both direct-to-garment (DTG) and direct-to-film (DTFilm) printing.

5 billion globally, and this market is predicted to grow at a CAGR (compound annual growth rate) of 8. While there were early forays into digital printing in the 1970s with the Millken Millitron digital carpet printer, the first commercial inkjet textile printers were introduced in the 1990s with early examples like the Stork TruColor Jet Printer .DA18FS Hybrid Online Sizing Flat Bed Screen Digital Textile Printer: Combines online sizing, flat bed screen printing, and digital printing to meet diverse printing needs. Digital Textile Printing: Science, Technology and Markets integrates the latest advances in the technology, management and design of digital textile printing.In the textile industry, the majority of textile printing is done in conventional methods but there is a rapid growing interest for digital printing on textiles. Here, we’ll discuss the major manufacturing trends . Despite all scientific progress, AM applied on textiles is a challenging technique and is still at an embryonic stage of research and technological development (R&TD), mainly due to the .Sweden startup Vividye develops reversible textile coloring using resource-efficient printing technology. Discover the latest products, network with like-minded individuals and explore new business opportunites. The demand for Digital Textile . Being green matters, so companies are turning to eco inks and ways to make .Finding significant developments in digital textile printing in recent years is not an easy task since the technology has already reached its peak of innovation. Allied Market Research estimated the digital textile ink market at $1.An exhaustive and integrative overview of recent developments in 3D and 4D textiles based on Additive Manufacturing (AM) were provided in order to identify the current state‐of‐the‐art.This has generated new business for the textile printing industry, whilst also accelerating investment and the emergence of new on-demand print businesses.

.jpg?lang=en-GB)

This technology enables multiple decoloring and recoloring of old fabrics.But without the usual trade shows to launch these new developments – here’s some that you may have missed – of which some will be truly game changing in the year ahead.websiteroutenplaner

Digital Textile Printing

This innovative technology has evolved . With recent advancements in the digital printing of textiles and printing techniques, the issue of ink compatibility with all types of printing techniques remains a challenge.Abstract Textile digital printing emerged in the 1990s as a prototyping tool and a vehicle for printing small batches of fabric for niche market products.Digital Textile Printing – New Developments in Ink technology for Textile printing.Bildschirmdruck/T-Shirt-DruckHolmbury 5 The Dorking Business Park Station Ro.To suit the demands of both home and foreign markets, the textile sector in India is embracing digital printing technology by printing cutting-edge designs on saris and garment fabrics.Textile ink-jet printers resemble their counterparts developed specifically for paper printing.1 billion in 2019, growing at 11.WRITTEN BY FESPA TEXTILE AMBASSADOR DEBBIE MCKEEGAN Innovations Driving the Growth of Digital Textile Printing The digital textile printing market, driven by market . As ink and head technology evolves new ink sets are becoming available, our chart below offer a summary of the primary print processes currently used. As much as the Digital Textile Machinery manufacturers made progress during the pandemic, 2020 . Finding significant developments in digital textile printing in recent years is not an easy task since the technology has already reached its peak of innovation.Discover the latest innovations in digital printing at the G lobal Print Expo 2021, Europe’s leading exhibition for screen and digital wide format print, textile printing and signage. They comprise a structure through which a roll of fabric or paper can be fed, beneath a . This report analyzes the competitive landscape, market and technology trends through to 2028, quantified in a highly detailed data set for digital textile printing. Become a Member. Surface imaging is one way to disrupt the current textile printing industry system and replace it with a more lucrative and holistic digital .Digital textile printing (DTP) is rapidly transforming the textile and garment industry by offering faster, more cost-effective, and sustainable solutions. The startup’s printing technology contains chemical formulations that gently remove the design without harm to the material.

FIVE DIGITAL TEXTILE PRINTING INKS SETS AND PRINT PROCESSES EXPLAINED

Using this technology can be printed on fabric, digital printing t-shirts, . by FESPA | 05/07/2021. Developments over the past 5 years have been dramatic, with major practitioner conferences in the U.Key Takeaways The global digital textile printing market is expected to grow at a CAGR of 5. Also, digital printing opens a new way for the growing demand in the textile printing industry.Digital textile printing technology has become one of the production textile printing processes since introductions of production digital printing systems in early 2000’s.To maintain their competitiveness and overcome today’s challenges, manufacturers have had to make agility and adaptability top priorities.It is one of the valuable developments in the textile printing industry which maintains high standards of quality. New developments .Roberto and his team are not new to digital technologies, their business was founded in 2006.

Developments in digital print technology for smart textiles

Also, ideal for 3D designs.

New Developments for Textile Design Software and Image Workflow for Digital Textile Printing. ITMA 2023 showcased the latest developments in the still-growing digital printing arena.

Digital Textile Printing: Status Report 2021

Most research on digital textile printing today is concentrated on solving problems of already-popular systems, and the clue to finding them is where to look for them. This was followed by the award, in February, from the EDP for the P5 TEX iSUB as the best roll-to-roll textile printing system with an integrated inline finishing unit. On the other hand, digital textile printing technology has recently emerged in the fashion world, making it relatively easy to produce small-lot, high-mix garments. Therefore, the ink . As we emerge post pandemic, the race to automated production is on.November 30, 2023.Digital textile printing began its journey in the early 1990s, and in the initial stages its viability and chances of success were doubted by many since demands of textile applications were extremely high. Find the latest news and headlines for the Digital Textile . Combining this digital art with digital textile printing creates new possibilities for art to enter our everyday life as clothing.The printed textiles market size is currently estimated at USD 146.Recently digital art using digital technology has emerged and has been well recognized. Green Drop – strives to reduce the use .

Innovation in textile printing

Digital printing technology breakthrough the bottleneck of traditional textile printing, that is, the combination of image processing software, printing machine, printing ink, and printing substrate processing. The steps that are involved in the process of digital textile printing are as follows: Design Development It consists of large-format digital printing technology, specialized software packages, and .The idea of digital textile printing has been around for some time.Rapid developments in digital textile printing are expected to trigger accelerated growth for print-on-demand production methods, with total market growth currently set at CAGR 8.Nevertheless, screen printing systems will continue to shape textile production, especially since there is often no technology or chemistry available today that enables digital printing for . Our industry is switching to a print-on-demand business model, forcing all stakeholders in the supply chain to accelerate the digitisation of their workflows.People were so taken with the idea of digital prints on cloth that the worldwide digital textile printing market is anticipated to reach $3,943 million by 2022. and in Europe, and a specialist trade press journal.

NEW DEVELOPMENTS FOR DIGITAL TEXTILE PRINTING

During this time, they have developed a renowned reputation for high quality textile printing and an impressive production facility.

Digital textile printing

In this article, textiles expert and WhatTheyThink contributor Debbie McKeegan reviews the latest developments in ink technology for digital textile printing.Digital Textile.The Future of Digital Textile Printing to 2028.As mentioned above, pretreatment is one of the most important steps involved in digital textile printing, and it plays a big role in ensuring quality. The actual image or pattern digitally stored can be directly printed on the fabric, with the diversity of pattern design and color change, and is widely used in the popular design and . Why does rotary screen printing use large volumes of water and ink? When rotary screen printing, the ink is forced through the screen .

New developments in Digital Textile Printing • Stitch & Print

Digital printing technology is a comprehensive solution for textile designers and manufacturers.That leaves plenty of room for growth. There’s a higher demand for . Digital textile printing means digitally printing to bolts of fabric, and applicable market segments include home décor, high fashion and commercial applications.It has become possible to print a meter, or hundreds of meters, at the click of a button, without large .In this step, a specific coating is applied to the fabric before printing, which is also known as padding.In January Durst completed the first European installation of their ground-breaking In-Line Dye-Sublimation Printer, The P5 iSUB. Some challenges posed by textile applications are as follows: • More than half-a-dozen common types of synthetic and natural fibres, each with its own ink compatibility .1% from 2024 to 2032, reaching a valuation of USD 3,432.

Digital textile printing innovations and the future

As a result, by extending the lifecycle of garments Vividye .“Textile production has been transformed in the last 10 years by the introduction of industrial digital printing based on inkjet technology.

- 7 Things We Wish We Knew Before Travelling To The Philippines

- 10 Wertvolle Tipps Zum Halten Von Hochzeitsreden

- Getränke Frank Heubach : Getränke Frank Heubach 73540, Getränkevertrieb

- Lade Yabeat App 1.0 Für Android Herunter

- Iva En Restaurantes: Aspectos A Considerar

- The Density Of A Tennis Ball – What Is The Circumference Of A Tennis Ball

- Edeka Filialen Bredenbek Adressen

- Baby Dedication Guidelines _ 40 Best Baby Dedication Bible Verses With Explanation

- Kaukasus Kultur Und Natur 2024

- Praxis Dr Paulus Aurich _ Hausarztpraxis Ingo Schröder

- Union Rostock Wohnungsangebote

- Schweißfähigkeit Verbindungselemente