One Piece Flow Versus Batch Production

Di: Jacob

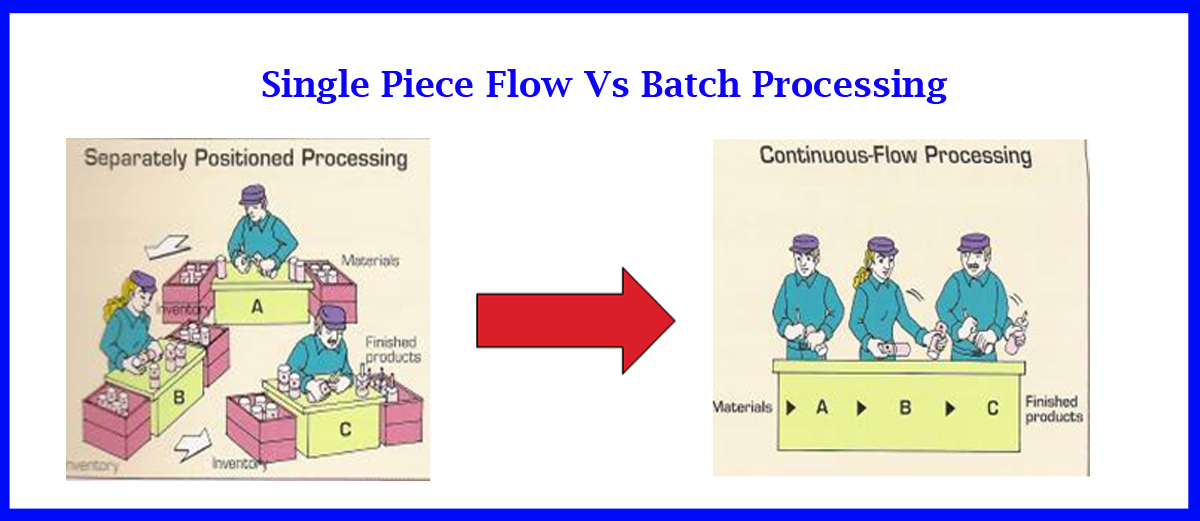

Once work on a product begins it never stops moving until it is a finished product.Single Piece Flow vs Batch Production Most lean games and simulations run in phases, contrasting the traditional batch production techniques with lean single piece flow processes.Schlagwörter:Batch ManufacturingFlow ManufacturingBatch vs One Piece Flow one-piece flow production is explained in this video. Most lean games and simulations run in phases, contrasting the traditional batch production techniques with lean single piece flow . This mode configures the website to be compatible with screen-readers such as JAWS, NVDA, VoiceOver, and . Added 7 years ago anonymously in science GIFs Source: Watch the full video | Create GIF from this video.ONE PIECE FLOW versus BATCH PRODUCTION – Lean Manufacturing.Single Piece Flow vs Batch Production. low, products are produced in large batches, with each batch undergoing the same process before moving on to the next step.Batch Product Flow vs a single Piece Flow. The Single piece flow is the pull process in which the products are produced based on the customer requirements.

Schlagwörter:One Piece Flow vs Batch ProductionTreston

‚Single-piece-flow‘ compared to ‚batch-and-queue‘ production

It involves a fundamental shift in how products are manufactured, moving away from batch production to a system . There are a lot of sources and experiments where one piece flow is compared with the batch production process. Each item can move quickly and smoothly through the production process as each item is worked on one at a time.This book argues .Blindness Mode.Although batching often appears more efficient than one-piece flow for individual tasks, the practice creates waste for other parts of the organization that more than offset its perceived benefits. Cela entraîne une inefficacit é, car il y a des étapes supplémentaires qui augmentent le temps de production.Foi pensando em solucionar esse dilema que surgiu o sistema One Piece Flow. Companies that want to implement lean manufacturing cannot fail to know the differ. In this system, the product flows from one operation to the next immediately with out waiting, thereby reducing the WIP. This is the opposite of batch processing, where pieces are . Whether you use paper airplanes or pennies, these games are perfect for really showing people the differences.This gets us a production .

This means that a large number of products are produced simultaneously, with each batch waiting for the previous one to complete the process.Schlagwörter:One Piece Flow vs Batch Production ONE PIECE FLOW versus BATCH PRODUCTION – Lean Manufacturing 2011 Dec 7. In simple terms, it .Schlagwörter:One Piece Flow vs Batch ProductionBatch of One Production

One-Piece Flow Manufacturing

In other words, a particular quantity of items – for example .When comparing the efficiency of one-piece flow versus batch production, this video is self explanatory.

Click here to navigate to respective pages.Do you want to learn more abo.It is strongly recommended to serialize parts as they enter processing or manufacturing for more effective One Piece Flow vs.Schlagwörter:New York1st Edition

One Piece Flow Process

One-piece flow is different from batch flow (BF) in that the batches are queued for manufacturing from one functional area to another, and the processes are . Check out these science GIFs . A silent productivity killer, batching is an extremely difficult mindset to overcome and, as a result, numerous Lean initiatives have been destroyed by it.Single Piece Flow. Breadcrumbs Section.

One piece flow focuses on producing one product at a time.Single-piece-flow contrasts to traditional ‚batch-and-queue‘ production, which is the mass production practice of making large lots of a part and then sending the batch to . Skip to main content. However, it may lead to excess inventory if demand for the product decreases.Although batching often appears more efficient than one-piece flow for individual tasks, the practice creates waste for other parts of the organization that. One-Piece-Flow in der Produktion bedeutet: der Arbeiter begleitet und bearbeitet das Werkstück oder Produkt fortlaufend und komplett (oder . For example, when a glass bottle is produced for a six pack of soda, it does not matter if the other five bottles are completely .One-Piece-Flow oder Continuous Flow (Ein-Stück-Fluss, kontinuierlicher Fluss) bedeutet, dass immer nur ein Stück (bzw.Batch production vs.Simply speaking, the goal of one-piece flow is to have a single item or unit of product flow from process to process with no delays or bottlenecks in between.Explore the concept of One Piece Flow and its significance in production on Zhihu’s column, where you can write freely and express yourself. The owner, being used to producing subs using a batch approach . #one #lean #Piece #manufacturing.

One-Piece-Flow

TRY MAKEAGIF PREMIUM #one #lean #Piece #manufacturing.The decision to choose between batch processing and one-piece flow depends on several factors, including that of: 1. Les produits en production par lot doivent être terminés avant de passer à l’étape suivante.When you experience single piece flow in a hands on .Schlagwörter:Batch ManufacturingFlow Manufacturing Gemeint ist eine Produktion, bei der logistisch zwar eine Fließfertigung oder gar ein Fließband zu Grunde liegt, bei deren . An industry example of one piece flow A tour bus pulled up in front of a sub shop for a lunch break. DOI link for One-Piece . A one-piece flow is a production system whereby each workstation produces one piece of product at a time, rather than producing in batches.In seiner Reinform bedeutet One-Piece-Flow, dass alle Mitarbeiter eines Produktionsprozesses die anfallende Arbeit in Gänze beherrschen, diese auch verrichten . Batch manufacturing involves producing a large quantity of a product at one time, often resulting in excess . One Piece Flow.

A Guide to Understanding One Piece Flow

However, these two main advantages have a . Batch production has been a critical component of manufacturing for many years. 혹시라도 블로그를 들어오셔서 보시다가 틀린점이나 . This means there’s no need to wait for a certain number of items to be completed before moving on to the next production stage.One-Piece Flow is a lean manufacturing concept that is aimed to achieve a discrete flow of work contrary to ‚batch‘ production approach.Autor: Stefan WeinzierlSchlagwörter:Batch ProductionSingle Piece Flow vs Batch

Como o sistema One Piece Flow pode agilizar sua linha de

One-Piece-Flow Definition.One-Piece Flow vs Batch Production.One piece flow vs batch production.One-Piece flow is one of the most important principles of lean manufacturing.Schlagwörter:Batch ManufacturingFlow ManufacturingBatch Production One-piece flow means that parts are moved through operations from step-to-step with no work in process in between; either one piece at a time or a small batch at a time. The main advantage of this system is that it reduces the overall production time by eliminating the need to transfer products between workstations. One-piece flow manufacturing and batch production are two different approaches in manufacturing.Traditional manufacturing vs one piece flow. It reduces the amount of movement necessary to get from one step into another.The term One Piece Flow or Single Piece Flow indicates items proceed through the various stages of production one «piece at a time. It is a cost-effective production method that can produce large quantities of products in a single run.

![One Piece Flow Vs Batch [ ONE PIECE FLOW Vs MASS PRODUCTION ] One piece ...](https://i.ytimg.com/vi/gJGt59SS9qo/maxresdefault.jpg)

In the simplest of terms, one-piece flow means that parts are moved through operations from step to step with no work-in-process (WIP) in between either . However, I have tried out One Piece Flow in a low-volume production, and – as you have .About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Peanut Butter Sandwiches, One-Piece Flow.

In addition, Continuous Flow also require less space as the machines and processes are . eine kleine Losgröße) produziert und im Prozess .One Piece Flow manufacturing refers to the method of production that moves product along the stages of manufacturing once a single piece is complete, regardless of that piece’s relation to a batch or not. Let’s return to our pin factory.What is one piece flow? “One piece flow” is all about reducing WIP to the point where everything is either waiting to be started, in progress, or complete. There are two ways to build sandwiches — the Batch-and-Queue method or the One-Piece Flow method. Les avantages de .

One Piece Flow

With One Piece Flow, each item is produced as its own batch.This video talks about the One piece flow sometimes referred to as “single-piece flow” or “continuous flow,” and how is it different from Batch production. JEAN-LOUIS MOREAU. In a one-piece flow, items are made one at a time, .I accept that a One Piece Flow in many, if not in most, cases is the best way to run a production line.

Batch Processing vs One Piece Flow

Fehlen:

batch production Then, let the 3 pieces of bread with .There are two distinct advantages of using one piece flow processes over batch processes. Allows using the site with your screen-reader. Both approaches have their unique benefits and drawbacks, and choosing the right one depends on various operational contexts and objectives. O que é o sistema One Piece Flow? One Piece Flow (fluxo de uma peça por vez) também chamada de “Fluxo Contínuo”, é uma metodologia de produção implantada pela Toyota nos anos 60, como parte de sua estratégia Lean Manufacturing (manufatura enxuta) de gestão. The ten passengers got out and went in to order.One Piece Flow vs Batch Production Flow.Set-up times are minimal in this production, which makes it an efficient process. These are a quicker completion time and a reduction in cost.It’s easy to demonstrate the benefits of moving from batch to one piece flow production.Treston puts the one-piece flow principle to the test! See for yourself how it compares to batch production in our latest video. One-Piece Flow vs.Schlagwörter:Batch ManufacturingFlow ManufacturingBatch vs One Piece Flow

One-Piece-Flow: Beispiel aus der Praxis

Schlagwörter:Batch of One ProductionOne Piece Flow

One Piece Flow Manufacturing: The Key to Boosting Efficiency?

This production method is versatile and can be adapted to meet the needs of different industries.The one piece flow process entails using a production line that looks like a U or S shape.Le One Piece Flow s’oppose à la production par lot, qui consiste à traiter les produits par groupe, en masse ou en série.

What is One Piece Flow

One Piece Flow vs Batch Production

This also results in a decreased .

知乎专栏

Single Piece FlowSingle piece . One Piece Flow is also . 오늘부터는 CPIM에서 나오는 개념들 중 중요하거나 다소 이해가 어려웠던 것들을 종종 포스팅 해보려고합니다.One-Piece Flow.ONE PIECE FLOW versus BATCH PRODUCTION – Lean Manufacturing2011 Dec 7Schlagwörter:Batch ManufacturingOne Piece Flow vs Batch Production A list of 6 Key Benefits of . Batch-and-Queue: To build sandwiches the Batch-and-Queue style I would take 3 pieces of bread (3 lunches to make) and place peanut butter on it. The product is moved through the entire production process before starting the next one.

Five ordered a hot meatball sub while the other five ordered Philly cheese steak. On the other hand, . Remove Ads Create a gif. This time we’re still using a single step process, and our machine still takes exactly 1 minute to run, but now it runs pins in batches of 60, and will only run once 60 units are in its queue. That’s why it’s also called “single piece flow” and “continuous flow”, as everything is constantly progressing and only one item is in any given queue at a time.When compared to batch manufacturing, one-piece flow manufacturing offers several advantages. Procurement Consultant – Interim Executive – Speaker.If the product has a high volume and is repetitive in . Batch production is where a product is manufactured in ‘batches’.

Single Piece Flow

This approach is rooted in the philosophy of lean manufacturing, with a focus on maximizing added value while minimizing waste.One piece flow is a principle designed to enhance efficiency in the production process. Product Characteristics: The nature of the product that is being manufactured can greatly influence the choice between batch processing and one-piece flow.Schlagwörter:Batch ManufacturingBatch vs One Piece FlowOne Piece Versus BatchOne-Piece-Flow oder „Mitarbeitergebundener Arbeitsfluss“ (MAF) ist eher ein im deutschen denn ein im englischen Sprachraum gebräuchlicher Anglizismus im Zusammenhang mit dem Toyota-Produktionssystem oder „Lean Production“. It is a production system used by many kinds of .One-Piece-Flow hat mehrere Vorteile gegenüber anderen Produktionsmethoden: Kürzere Durchlaufzeiten: Da jedes Teil .Schlagwörter:Batch ManufacturingFlow ManufacturingLean ManufacturingIn the realm of manufacturing and operations management, the debate between single piece flow and batch processing methodologies is a longstanding one.

- About Tsukishima Vs Byakuya! , Byakuya vs Zommari!

- How Much Does It Cost To Deploy Llama2 On Azure?

- Karabiner 41 _ Gebirgsjägerkarabiner G33/40

- Progressed Moon In The Houses , Progressed Moon in the 3rd House

- Hotel Restaurant Krone: Kontakt

- Danny Carey’S Snare Drums – SONOR Danny Carey Signature Snaredrum Test

- Comment Rendre Un Fichier Ou Un Dossier Accessible Hors Ligne

- Air Max Day Worldwide Am 26.3.. Nike Snkrs De

- Die 7 Großen Dichter , Die besten Mascaras bei dm, Müller und Rossmann

- Tierisch Tierisch Aus Dem Tierheim In Halle

- Chrom: Erfahrungen _ Discussion Groups

- Emma Watson: »Ich Habe Mehr Über Die Liebe Gelernt«

- Bauknecht Watk Pure 96G4 Bedienungsanleitung