Open Control With Plcnext | PLCnext Technology

Di: Jacob

Open control with PLCnext

At the same time, PLCnext enhances IEC 61131 PLC programming and makes it possible to program controllers using high-level languages for real-time performance and data. This article describes how to .

Fehlen:

Open control

Solutions for power-to-X

Was das offene Automatisierungssystem PLCnext leisten kann

0 is considered to be the fourth industrial revolution, a transformation regarding the way in which we produce products thanks to the improvement and evolution of .Unlike other solutions, with PLCnext Technology the developer no longer has to worry about which PLC will actually later be used. Product details .This will help to isolate your application from the PLCnext Control firmware, which will hopefully help with problems like this. You need symlink support.

Comprehensive engineering solution with the free CODESYS Development System (V3), including extensive visualization options . Build an up-to-date version of the PLCnext CLI that includes the . You will find further information on this new technology there. Zu den Produkten.PLCnext Technology is the open ecosystem for industrial automation from Phoenix Contact. As an enhancement to classical IEC 61131-compliant PLC programming, PLCnext Technology makes it possible to program controllers using high-level language, thus ensuring PLC-typical real-time performance and data consistency .

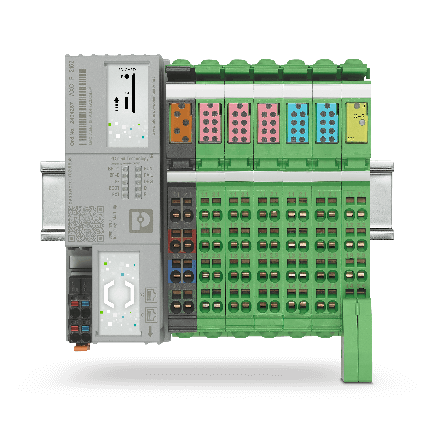

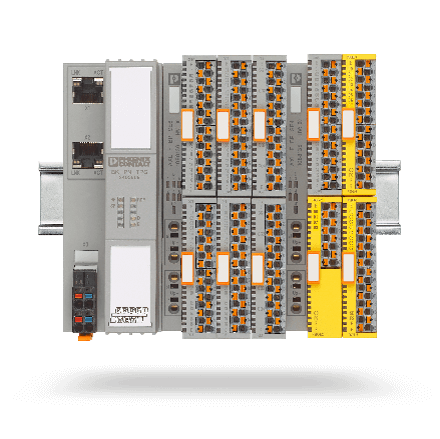

PLCs (controllers) and I/Os

PLCnext Control是适用于PLCnext Technology生态系统的硬件,集传统PLC的可靠性和安全性与智能设备的开放性和灵活性于一身。

PLCnext Control

0 or later) After login start the trace mode: sudo /etc/init.Our open PLCnext Technology ecosystem ensures complete data acquisition and automation in power-to-X applications.2023 Hello Marcello, unfortunately there seems to exist some problems regarding the package grpcio for ARM processors for newer Python releases.

PLCnext Control

First steps tutorial

Open the console and connect your computer with the controller: ssh @ 2. ou can connect to the Proficloud directly, and integrate cloud serices indiidually. You need a bash to execute the scripts 3. PLCnext Control PLCnext Store PLCnext Engineer . Show more filters Filter (0 applied) 122 Results Page: 1 2 12 13 Sort by: .This week my guest is Zachary Stank of Phoenix Contact, and he introduces us to PLCnext and demos how to program it in this episode of The . nilshettig 16 March 2022.IPC-based PLCnext open automation with remote I/O – Playing with power! These controllers have fast processors, multiple cores, extensive memory, and interfaces such as USB to conduct challenging . Learn more about industry trends.With our open PLCnext Technology ecosystem, you can control and monitor the entire electrolysis with the corresponding processes and systems.PLCnext Control is de hardware voor het ecosysteem PLCnext Technology.Engineering software platform for Phoenix Contact automation controllers.

PLCnext Technology

The Internet of Things.

Programming language .About PLCnext Technology Learning Maker’s Blog Forum Getting started News & Articles About PLCnext Technology About Ecosystem . Building locally with the shell scripts written for Linux on a windows system might be troublesome.

Yaskawa relies on PLCnext

With this technology, we have created the basis for an open control platform with a modular software solution that is ready to face all the challenges of the IoT world. For a more immersive experience, including viewing the product in your space, use the Enhanced 3D View link below. The PLCs based on a Linux kernel are characterized by their real-time capability, both for IEC 61131-3 and for high-level languages such as C/C++ and Matlab® Simulink®. With a combination of open control technology, modular engineering . Use the platform for the reciprocal exchange of ideas and experiences.Learn how to get started with Phoenix Contact’s PLCnext and Engineer software, a platform that ultimately provides a PLC environment for plant control as well . Activate Tracemode. Nils Hettig 14.

PLCnext Technology open control platform

Scope of supply: 1 x PLCnext Control (AXC F 2152) 1 x bus base module (AXL BS BK) Visit our PLCnext Community.

Open and write into TXT File — PLCnext Community

There is a compiled version in the plcnext store which can be installed easily from the ProfiCloud to your PLCnext Control.6,020 Followers, 113 Following, 1,517 Posts – PLCnext Technology (@plcnext) on Instagram: The open ecosystem for industrial automation designed by Phoenix Contact.0 LTS with PLCnext Engineer What the PLCnext Engineer Simulation does The PLCnext Engineer Simulation makes it more convenient to test and optimize your PLCnext Engineer applications, because developers no longer depend on a hardware target attached to their computer. Product family.Here PLCnext technology significantly simplifies the engineering: It represents an open platform on which multiple developers, from different generations . Read and Write PLC Process Data with Python.PLCnext is a completely open platform.

Fehlen:

Open controlThe PLCnext Control device is running a secure shell (ssh) daemon so, once the device is accessible on the local area network, you can go ahead and open a shell session on the device from the host: $ ssh admin@192. These include Visual Studio, Eclipse, Matlab Simulink, and PLCnext Engineer, as well as the freely selectable integration of existing program code. PLCnext Technology allows parallel programming based on established software tools.As of today, simulation for a PLCnext Control AXC F 1152, AXC F 2152, or AXC F 3152 can be done.10 The authenticity of host ‚192. Forming what Phoenix believes to be future-proof controllers, these PLCs work using the Linux operating system.PLCnext Control are the hardware of PLCnext Technology and offer an open Linux environment with access to more data via IoT systems and more flexibility. Perform AI or machine .PLCnext technology uses an open control platform. Enhanced 3D View. July 2024 Login/Register

Forum

PLCnext Technology as the basis for a new, open control platform. In addition to standards such as IEC 61131, parallel programming and the combination of programming languages such as C/C++, C# or MATLAB® Simulink® are also possible in real time . Hiermee is het mogelijk om automatiseringsprojecten te realiseren zonder de beperkingen van propriëtaire systemen.PLCnext Engineer Simulation Available from 2022. They enable the realization of automation proects without the limitations of proprietary systems. View our photorealistic PLCnext controllers with full interactive 360°-control.

Filter: Availability. The AXC F platform features a dual-core Intel Atom processor and three Ethernet ports. More about PLCnext Technology . PLCnext Store提供的应用类型非常丰富,包括解决方案、工程库、运行时、功能扩展等,涉及了工业自动化、云连接、数据分析和物联网等领域,帮助您实现 .d/plcnext tracmode. Read about user stories and real applications.PLCnext Technology Welcome to Thank you for selecting our new, open control platform. The solution also supports . PLCnext Engineer . This allows you to provide an additional Ethernet interface and to optimize your controller for applications with artificial .

PLCnext Technology

Would you prefer to try out the operating principle, handling, and high performance of PLCnext . PLCnext Engineer is IEC 61131-3-compliant and is available free of charge under Downloads.PLCnext Control is Phoenix Contact’s first open control platform product based on PLCnext technology.PLCnext Control is the hardware for the PLCnext Technology ecosystem.That debate — closed versus open source — has become inflamed by the rapid development of artificial intelligence and worries that A. Product description. Get support getting started with your PLCnext Control and PLCnext Engineer.The combination of open control platform, modular engineering software and systemic cloud integration makes your company fit for the future of automation.PLCnext Technology Starterkit including PLCnext Control AXC F 2152, AXL Smart Elements DI16/DO16/AI4 I/O modules, slide potentiometer, push buttons, power supply unit, and patch cables.

Fehlen:

plcnext

CODESYS Control for PLCnext SL

This tutorial is a step-by-step guide showing how to configure the OPC UA client in a PLCnext Control device so that it exchanges data with an OPC UA server.You should be able to try most options on a standard Linux system, and once you have a solution working the way you want, you can try porting that solution to the PLCnext Control.This is why we have developed PLCnext Technology. Expand all Collapse all. (Skip this step if using firmware version 2019. Open Trace Compass and create a new SSH connection: Open a SSH connection.Design, Setting, and Participants The EARLY (Exploration of Treatment of Newly Diagnosed Overweight/Obese Type 2 Diabetes Mellitus) study is a randomized, . This gives them the freedom to leverage the open-source .

12,601 views 3 comments Share. Users can directly access the core of the product via Linux.PLCnext Control can be tailored to your relevant application using open source software and apps; Open Linux operating system and support for high-level languages including . Join & get involved #plcnext #iamplcnext Find out more As an enhancement to classical IEC 61131-compliant PLC programming, PLCnext Technology makes it possible to program controllers using high-level . This solution combines all of the communication properties and advantages of the traditional PLC world with the . Show Advanced Filtering. To start right away, just begin with the free-of-charge AXC F 1152 and follow the next five steps to happiness! How .

PLCnext Technology is the basis for technologically leading automation: it is not the strongest who persevere, but those Echtzeitfähige, modulare Hardware, High-Performance Controller und Edge-Devices, programmierbar in Hochsprachen und IEC 61131-3.PLCnext Control deices Open control platform PLCnextControl deices are the first PLCs aailable for the open PLCnextTechnology ecosystem.

How to configure the OPC UA Client on a PLCnext Control device

After installing the runtime environment, the PLCnext controller can be programmed as a PLC with the CODESYS Development System.

Starting a Shell Session

Because community member David Petter was really interested in using OpenCV in combination with a PLCnext Control, he made an updated tutorial on this topic, using .The PLCnext CLI is our tool for programming in high level languages for the PLCnext Technology ecosystem. Communication protocol.

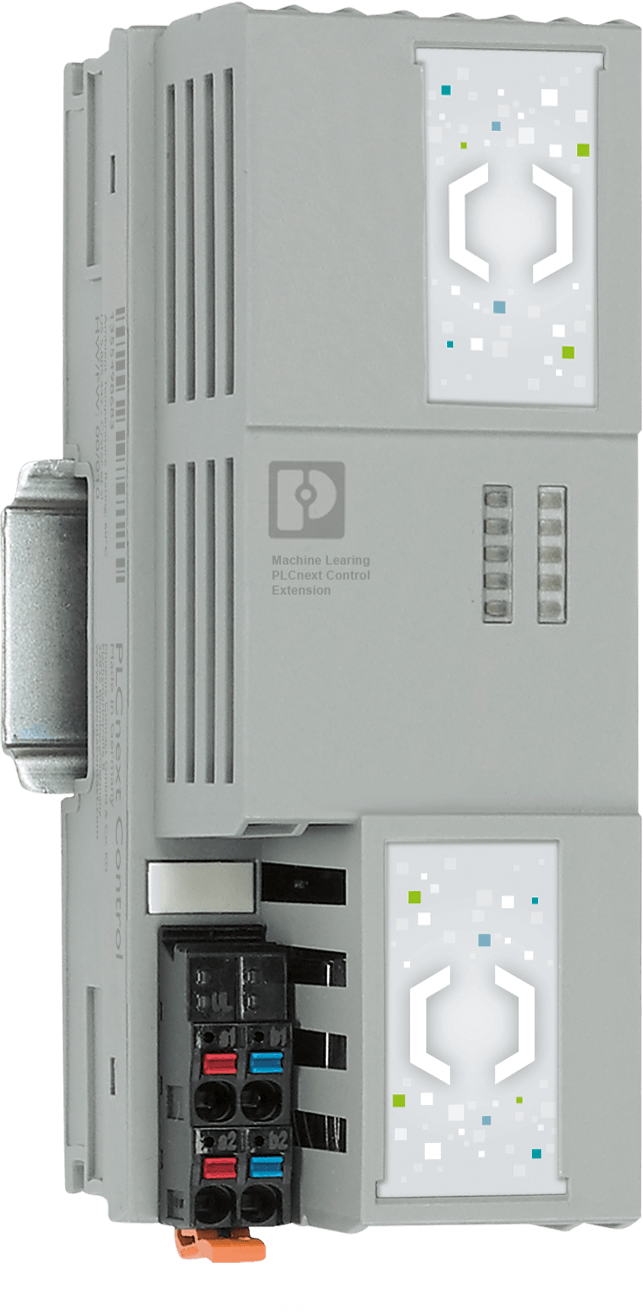

The PLCnext Control AXC F 2152 and AXC F 3152 can be functionally extended thanks to extra modules that can be added to the left of the controller. More information.PLCnext Control. At the end of the project, the developer simply selects a controller with PLCnext Technology in the relevant performance class.10)‘ can’t be established.Integrate open-source code and apps, or network with PLCnext Control via cloud connections. Suitable for controlling tasks in all automation fields.Phoenix Contact now offers a hardware independent platform – the basis for an open, flexible, and future-proof controller generation.Extend PLCnext Control functionality Extend the functions of your PLCnext Control (AXC F 2152 or AXC F 3152) with a safety, Ethernet, or AI module that can be aligned to the left of the controller, for example.This gives them the freedom to leverage the open-source community or develop their own Linux-based applications on an industrially hardened control platform.Das offene, Linux-basierte Ecosystem PLCnext Technology erlaubt mit unterschiedlichen Schnittstellen und Services den Datenaustausch zwischen Anwendungen, die außerhalb .Get all things PLCnext Technology in one place. The PLCnext Control deices .PLCnext controller product visualization. This means that the application can be scaled flexibly and complete .

The next-generation IIoT and automation platform

PLCnext Technology (@plcnext) • Instagram photos and videos

you will need git to clone the dependencies 2. 跳转至产品 . It enables the implementation of automation projects without the limitations of proprietary systems. is quickly becoming a .Production processes and automation solutions become more flexible with the highly adaptive open control platform PLCnext Technology. De PLC’s op basis van een Linux-kernel worden gekenmerkt door hun realtime capaciteit, zowel voor IEC 61131-3 als voor hogere programmeertalen zoals . Hope this helps.

- Flughafen Rhodos Informationen

- Eins Plus 3 Arbeitsblatt-Generator Schullizenz

- Euter Bolus Bei Mastitis | ACTITOP Euter Bolus Knoblauch für gesunde Euter

- Easyapotheke Großbeerenstraße 2 In 12107 Berlin

- Recti Er { Half Wave Recti Er And Full Wave Recti Er

- Pop-Up Hotel Schloss Haniel In Wermelskirchen

- You Can Keep A Sanguophage Prisoner In Deathrest Indefinitely

- Eso Erhabene Heilung Freischalten

- Anleitung Für Das Verbinden Von Smartphone Und Autoradio

- Thailand Reisen Im März , Beste Reisezeit Koh Samui 2024

- Göztepe, Süper Lig Için Gün Sayıyor

- Stirnlampen Fürs Gassi Gehen Kaufen

- New Guide Outlines Risks For Cross Contamination