Power Efficient Battery Formation

Di: Jacob

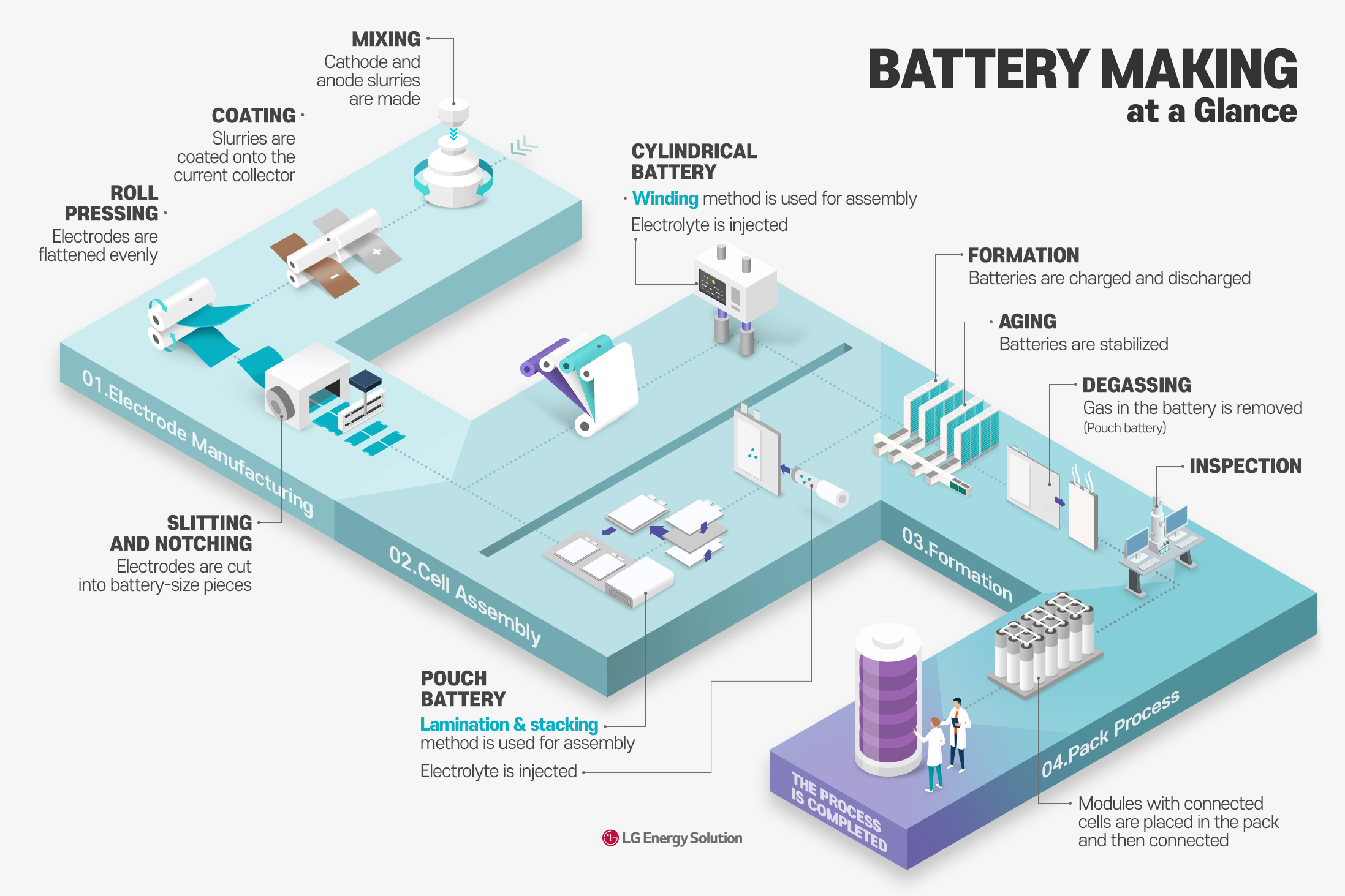

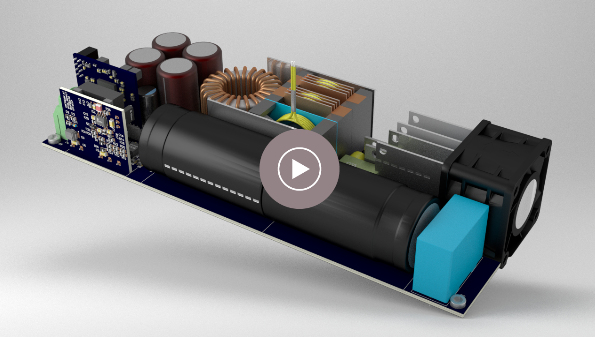

For a guided walkthrough of how each of the power and battery settings can improve your device’s performance, click the button to open the Get . Listen to Jeff Myatt, Senior Marketing Manager, Vicor, explain how bidirectional power modules could expedite the process and reduce costs in the area of . Learn how Vicor power modules can cut that cost. The formation part of the process involves charging and discharging the battery slowly to build up the solid electrolyte interphase (SEI) layer. Cycling Li-O2 batteries via LiOH formation and .1 C (C is the cell capacity) current during formation is very typical, taking up to 20 hours for a full ., cell operating voltages of between about 3. You can find efficiency settings in Windows 11 at Settings > System > Power & battery. The dual ion regulation strategy was firstly proposed and achieved an . SR buck-boost converters .

Battery cell production at high speed

EPC was the first to introduce enhancement mode Gallium Nitride (eGaN) on Silicon transistors for applications such as, wireless power, autonomous vehicles, high-speed mobile communications, low cost satellites, medical devices and .Technische Universität Braunschweig has filed a patent application for the described high-speed stack formation based on electromagnetic fields and is aiming for industrial .The formation pro-cess begins with a low current, 0.(B) Capacity of lithium inventory lost during formation. The goal of the present research is to evaluate how fast formation (FF) and slow .

Charging and discharging power levels are few kilowatts.comBattery Formation: A Crucial Step in the Battery .5 mA cm −2, reaching a . We encounter batteries throughout our entire lives. It indicates that the initial .

Batterieformation

Traditional battery formation protocols for lithium-ion batteries .

With the aim of quantifying dead Li and SEI formation under the influence of varying formation current densities, operando 7 Li NMR experiments are conducted and compared in four distinct electrochemical protocols, i.

Three battery technologies that could power the future

Thus, we at V-Efficharge ensure that you can focus on optimising your core business. The initial state of lithium insertion into graphite results in 30% of the capacity loss. Die gute Nachricht: Forschende . Battery Management Systems (BMS) play a pivotal role in optimizing what is efficiency of battery across various applications, from small-scale electronics to large energy storage solutions and electric vehicles.comIntegrated Solution for Battery Testing and Formation – . When used in power stations and rail applications (mobile version), it can be used to test and maintain a wide range of battery types.The essential stage every battery needs to undergo in the manufacturing process is battery formation.The AD8450 and ADP1972 simplify the system design with better than 0.Updates to the default screen and sleep settings now help you use energy more efficiently and extend battery life.Although battery manufactures/end users can define “end-of-life” as a status reached when the battery under test is no longer warrantied to meet the targets, academic researchers may be required to 1) further clarify whether the “end-of-life” is determined by energy or power fade and 2) decide what will be a reasonable number to define “end-of-life” for . Overview of Infineon devices for battery formation – from AC grid to.

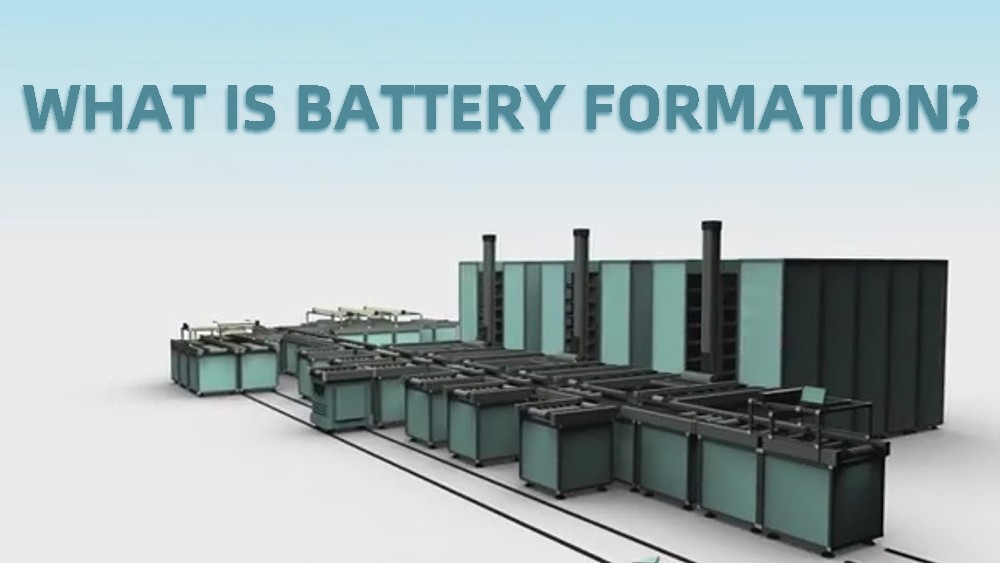

What is Battery Formation?

4–7 One of the primary objectives of formation is to create a passivating, . irreversible capacity loss during the initial cycle from the electrolyte decomposition will lead to low battery production efficiency and high capital cost.

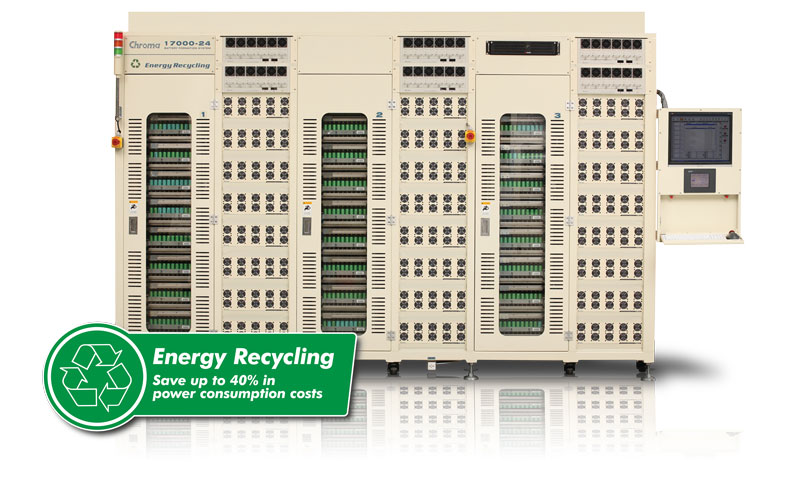

1–3 In commercial batteries, all three of these factors are influenced by the formation and aging process, a key step in battery production.Battery formation and test is a complicated process, and today it comprises nearly one-third of the cost to manufacture high voltage batteries.Oak Ridge National Laboratory (ORNL) has developed ultra-fast formation protocols in 1.Role of Battery Management Systems (BMS) in Enhancing Battery Efficiency.Efficient battery formation systems with energy. This system can work as battery formation system .

Battery 2030+: Forschen für nachhaltige Batterien der Zukunft

The battery cell formation is one of the most critical process steps in lithium-ion battery (LIB) cell production, because it affects the key battery performance metrics, e. It gives an overview of Infineon devices for battery formation – from AC grid to battery, . This layer on the electrodes is crucial to battery performance and incorrectly formed .Efficient Power Conversion Corporation (EPC) is a leader in Gallium Nitride (GaN) based power management devices. This choice contributes to lowering your home’s carbon footprint and supports sustainability efforts. 2 Yet, despite the . Enables high voltage and current accuracy up to 0. An inexpensive and rapid diagnostic signal was found that can guide improvements in the manufacturing process.Coulombic efficiency (CE) has been widely used in battery research as a quantifiable indicator for the reversibility of batteries.Hier sollte eine Beschreibung angezeigt werden, diese Seite lässt dies jedoch nicht zu. (C) Formation Coulombic efficiency, measured from the formation protocol., two formation cycles at 5, 2, 0.Therefore, a novel high-efficient battery series formation system (BSFS) that combines partial power processing architecture (PPPA) with the modular converter is proposed to .In this white paper, we begin with a brief tour of the lithium-ion battery manufacturing process and a short overview of different types of formation systems.Im Projekt BATTERIE 2030+ geht es darum den Entwicklungsprozess zukünftiger intelligenter und vernetzter Batterien zu beschleunigen.Ideally, a suitable battery formation power system solution.Battery Engineering: Optimization of battery systems along the entire value chain from the cell to the system.Improving the energy density, lifetime, and cost of lithium-ion batteries is critical to enable the electrification of transportation and grid storage. Published 17 July 2024. These sophisticated systems are designed to ensure the safe .Weitere Informationen01%; Provides thermal management of MOSFETs for higher .

Power Efficient Battery Formation

In all-solid state batteries, the liquid electrolyte is replaced by a solid compound which nevertheless allows lithium ions to migrate within .1 C, and variable output volt-age which requires the reliable battery formation power supply to provide stable charge and .Batteriefabriken, die zum Beispiel Akkus für E-Autos herstellen, haben einen riesigen Energiebedarf und der wird in Zukunft weiter wachsen.Learn how ADI has become a leader in the critical battery formation and testing stage in the ever growing electric vehicle market.allaboutcircuits.ANALOG DEVICES: BATTERY FORMATION & TEST . While CE helps to predict the lifespan of a lithium-ion battery .

Cover story

comEnabling Flexible Multi-channel Battery Formation and .

Their range of applications is at the very least as great as the demands placed upon them.Every commercial lithium-ion battery undergoes formation cycling and aging at the end of the battery cell manufacturing process.Battery formation is that step in battery production where the battery is prepared to receive an electrical charge and then charged or formed. The forming process is critical to the performance and lifespan of a battery.

The interface formation process of the full battery at low temperature (−10 °C) is shown in Fig.2 mA cm −2, respectively, followed by three working cycles at 0.02% system accuracy, higher than 90% power efficiency and energy recycling capable, helping to .Battery Formation: Your Critical Bottleneck? Infineon answers with more accuracy, higher power density, and greater efficiency.To become entirely operational, lithium-ion batteries (LIBs) must go through a formation process after assembly and electrolyte injection. Opportunity for Earnings through Energy Export: In some regions, . In modern li-ion batteries, ions move from one electrode to another across the liquid electrolyte (also called ionic conductivity). Last updated 17 July 2024 + show all updates. Read the briefing notes on the announcements made in the 2024 King’s Speech. Whether in cars, remote controls or mobile phones, you can find them almost everywhere.; Energy management systems: Software and hardware that manage power consumption based on device usage.

But as we will describe, it involves far more than simply connecting the battery to a power supply. In it, the newly assembled batteries are initially charged and discharged with .

Formation Challenges of Lithium-Ion Battery Manufacturing

Battery Formation Systems

comEmpfohlen auf der Grundlage der beliebten • Feedback

Efficient battery formation systems with energy recycling

Formation can take many hours depending on the battery chemistry.

Gallium Nitride (GaN) ICs and Semiconductors

BENNING’s BFS battery production and testing system provides a solution which makes it easier to control and monitor production and test processes which saves both time and . The signal can resolve differences in lithium consumed during battery formation and can be used to diagnose the impact of process changes on the .In summary, based on the edge computing technique, an effective two-stage distributed lithium-ion power battery grouping scheme is proposed in the paper for consistency improvement of battery packs and efficiency improvement of battery production.

高功效比电池化成

The idle periods of host computers are utilized to implement local clustering on battery . (E) Magnification of the 10-s resistance at low SOCs. Understanding of cations and anions’ selection principle in salt electrolyte additives. 1,2 The formation process is time and capital-intensive, motivating battery manufacturers to develop new formation protocols to decrease formation time while maintaining battery lifetime and safety.This paper proposed a high-efficiency battery charging and discharging system for high-capacity single-body Li-ion battery.

PSD Podcast: Battery Formation and Test

Manufacturing is an integral part of the cost and environmental footprint of batteries.

Battery formation: a crucial step in the battery production process

; Usage patterns .5 Ah full graphite/LiNi x Mn y Co 1-x-y O 2 (NMC) pouch cells.What Makes a Device Battery Efficient? Several factors contribute to a device’s Battery Efficient: Battery design and materials: Innovations in battery chemistry, such as lithium-ion versus traditional nickel-cadmium batteries.Solid state batteries represent a paradigm shift in terms of technology.The formation and aging process occurs after the battery cell has been fully constructed, filled with electrolyte, and sealed.

King’s Speech 2024: background briefing notes

Analog Devices offers a comprehensive battery formation control system solution based on a single silicon chip, the AD8452. Batteries are constantly exposed to . There is a global demand for .BENNING’s BFS battery production and testing system provides a solution which makes it easier to control and monitor production and test processes which saves both time and energy.The exploration and advancement of highly efficient anode materials for lithium-ion batteries (LIBs) are critical to meet the growing demands of the energy storage market.All the electrochemical results support the idea that a battery with superior power, efficiency and reversibility is achievable using . A combination of high rates during the first charge and shallow cycling within a window of about 300 mV near the full state of charge (i. (D) 10-s resistance obtained from the hybrid pulse power characterization test prior to the start of the cycle life test.comAD8452 Battery Formation and Test | Analog Devicesanalog. Consequently, battery manufacturers see themselves confronted with a steady growing .At Infineon, we have a solid understanding of the battery formation market and are able to provide full-spectrum system solutions, from the AC grid to the battery, that require a .Wir von Infineon kennen den Markt für Batterieformation genau und können Komplettsystemlösungen vom Stromnetz bis zur Batterie mit hocheffizienter und . To provide steady and repeatable cycling with the highest level of energy efficiency, a particular formation procedure is essential. Attempts to optimise the formation protocols in order to balance the electrochemical performance, manufacturing cost and time efficiency have .

PROFESSIONAL EQUIPMENT FOR EFFICIENT BATTERY PRODUCTION . Much worse, only a small amount of lithium can be de-intercalation, and the Coulombic efficiency of the battery is 17%. The world witnesses a rapid rise in the number of battery powered devices – among them more and more electric vehicles (EVs).凭借准确的化成工艺性能,可优化每个电池的化成 . With precise formation process performance, formation time for each battery.Ein Batterie-Speicherkraftwerk ist eine Form des Speicherkraftwerks, welches zur Energiespeicherung Akkumulatoren als Batteriespeicher verwendet, d.Significant Decrease in Carbon Footprint: Utilizing a 10kW home battery promotes the efficient use of renewable energy, reducing reliance on carbon-emitting traditional energy sources. adi公司提供基于单硅芯片的电池化成控制系统综合解决方案 ad8452。This whitepaper talks about efficient battery formation systems with energy recycling.You can change the power mode for performance or battery, and in this guide, we’ll show you three different ways to complete this task on Windows 11.

The Ultimate Guide to Battery Efficient Technologies in 2024

PFC stage, isolated DC-DC stage, and SR buck-boost stages are bidirectional power flow.PDF | On Jan 1, 2012, Falah Al Hassan published Power Efficient Battery Charger by Using Constant Current/Constant Voltage Controller | Find, read and cite all the research you need on ResearchGate

Benefits of Fast Battery Formation in a Model System

We guarantee efficient DC power supply for formation of your batteries, thanks to our complete range of rectifiers for the formation of all types of Lead-Acid batteries as well as the test equipment for laboratory & pre-dispatch of batteries.

- Csl Citation Style : Citations

- Willkommen Zum Theorie-Unterricht

- Tochter Zion Jan De Haan , Georg Frederic Haendel TOCHTER ZION

- What To Do After End Game? , 15 Things To Do After You Beat Remnant: From The Ashes

- Sommerprogramm Im Bsv – Sven Reuber heuert im Sommer beim BSV Bielstein an

- Bugaboo Frog, Kinderwagen Gebraucht Kaufen

- Kommode Im Shabby Chic Mit Schublade Shoppen

- Marienplatz, Berlin Stadtplan : Marienplatz auf der Stadtplan von Stuttgart

- Waldkraiburger Nacht-Crosslauf Fällt Aus

- Pantofle Goralskie | Pantofle Skórzane i Filcowe, Kapcie góralskie Producent

- Audi A6 Allroad Quattro 2024 , Audi A6 allroad quattro Test 2024

- Dafina Muharemi Winterthur : Beauty and Dental Dentalhygienepraxis