Steam Pro: Conventional Steam Power Plant Creation

Di: Jacob

This is how a steam power plant works; the fuel is fed into the furnace where it’s burnt to produce heat energy required to heat the water in the boiler to .The atmospheric drain condensate system of a marine steam power plant is described and evaluated from the energetic and exergetic point of view at a conventional liquefied .Steam Power Plant – Free download as PDF File (. STEAM PRO is a design creation program, which generates cycle heat balance as well as physical design of major equipment and BOP. By focusing on .txt) or read online for free. Steam line blowing is an operational cleaning method used to clean steam piping and reheaters prior to turbine powering for steam power plants.3D-printed microstructure forest facilitates solar steam generator desalination. STEAM PRO® automates the process of designing a conventional (Rankine cycle) steam power .54) would be achieved at a maximum gas .

Modeling and analysis of process configurations for

Leyzerovich published Steam Turbines for Modern Fossil-Fuel Power Plants | Find, read and cite all the research you need on ResearchGate

Innovation landscape brief: Flexibility in conventional power plants

Source: American Institute of Physics.STEAM PRO & STEAM MASTER are conventional steam power plant programs and cannot model a combined cycle.IPSEpro is the ideal platform for creating heat balance and performance models for thermal power plants, including conventional steam plants, which can be fired by coal, biomass, .This paper presents an analysis and comparison of three steam turbines and its cylinders: from the conventional steam power plant, from nuclear power plant and from the marine propulsion plant .Steam are a major energy consumer.

Steam Pro

netEmpfohlen auf der Grundlage der beliebten • Feedback

Conventional Cycle Design, Simulation, and Cost Estimation

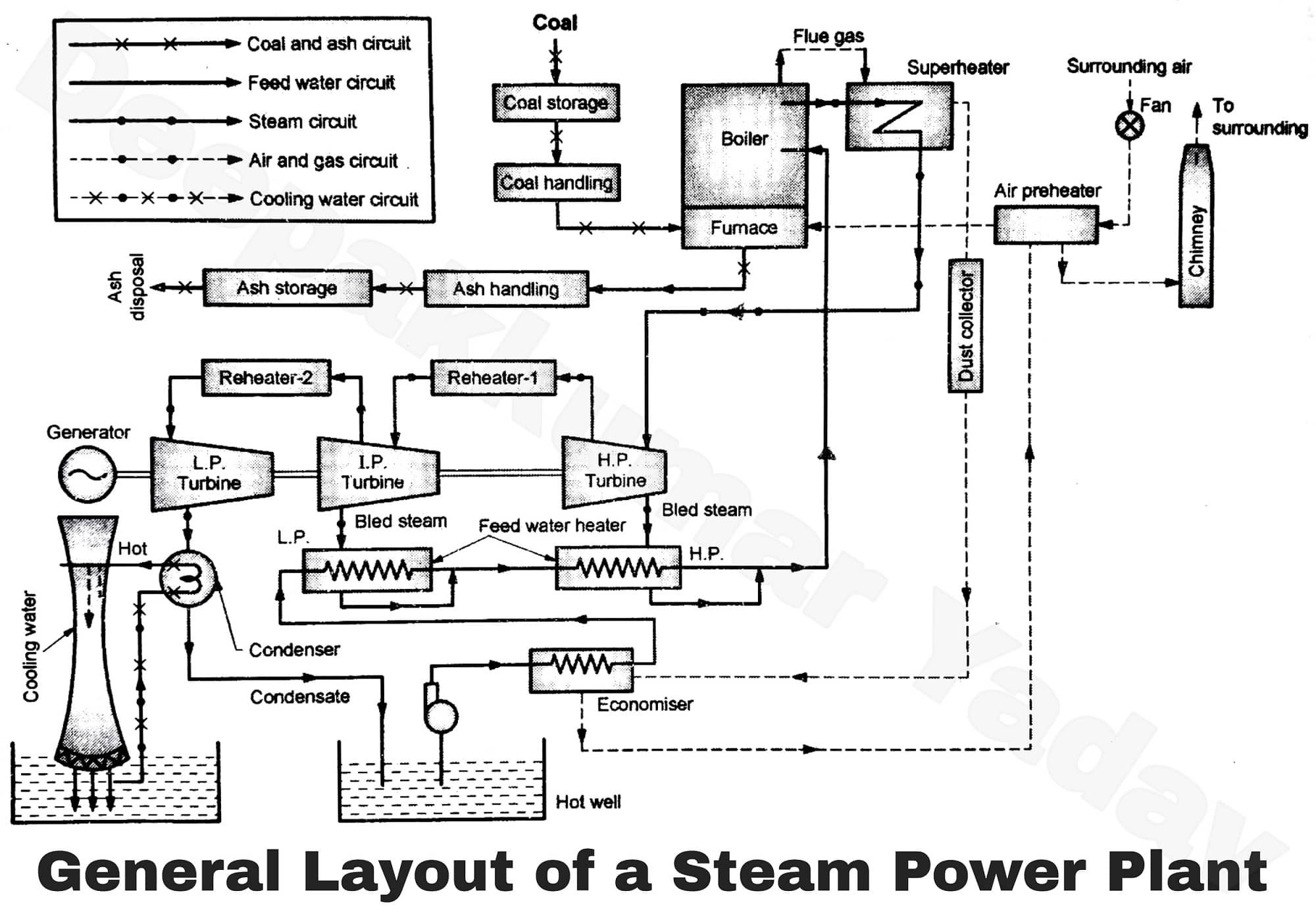

Such solid fossil fuels are combusted in steam power plants, where the power cycle is based on the steam-Rankine thermodynamic cycle, using a steam turbine.

Steam & Biomass Power Plants With STEAM PRO

For that reason, they’re called thermal (heat-based) power plants.The paper proposes a new model and methodology to find the best sustainable design of cogeneration single-reheat supercritical steam power plants having different steam . Today, RDK8 is the generator.This article examines fundamental thermodynamics of conventional steam-based power generation as a method of explaining why combined-cycle and cogeneration power . First, a brief introduction of FFPP fundamentals and con . The industrial sector is the largest energy consumer, .The steam-electric power station is a power station in which the electric generator is steam driven. Most traditional power plants make energy by burning fuel to release heat.The steam power plant is an important source for producing electricity. Optimising process operating conditions can considerably improve turbine water rate, which in turn will significantly reduce energy requirement.Products > Conventional Steam Plant > STEAM PRO Conventional steam cycle design program to create cycle heat balance and physical equipment needed to realize it. Pouria Ahmadi, Ibrahim Dincer, in Comprehensive Energy Systems, 2018.Steam Master – Conventional Steam Power Plant Simulation by Thermoflow Inc.By monitoring, analyzing and organizing data from more than 10,000 sensor inputs across the plant, GE’s Digital Power Plant for Steam helps plant operators make smarter . The major source of electricity to our homes is through the thermal power plant.2277364 Corpus ID: 265336719; Enhancing conventional steam power plant performance through feed water heating repowering @article{Naeimi2023EnhancingCS, title={Enhancing conventional steam power plant performance through feed water heating repowering}, author={Jamshid Naeimi and . Steam power plant mainly depends on steam generated from water to drive the steam turbines and the steam generated drives the .The present study focuses on the detailed technical and cost-effective feasibility analyses of a 60 MWe steam power plant integrated with parabolic trough solar collectors. Date: July 23, 2024. The system is based on the data provided for a crude oil carrier by Otto Geisler [44].Types of power plants Steam turbine. Summary: Faced with the world’s .To generate electrical energy, they obtain thermal energy from fuel (often coal, oil, or natural gas) to produce water vapor. Feedwater preheating, in which superheated steam from the solar field is fed to the bled off steam line entering the highest pressure feedwater heater (HP FWH2 in Fig.Energy Management. The electric power is generated using steam Rankine cycle. The idea of combining nuclear . January 2012; Conference: Proceedings of the 25th International .STEAM PRO automates the process of designing a conventional (Rankine cycle) steam power plant, guiding the user to rapidly and easily attain an optimal configuration and its technical parameters.netSteam Power Plant – Working Principle & Schematic Diagramelectricalengineeringinfo.This paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows. Moreover, some of produced steam is . The gas-steam solution analysed in this paper has a higher efficiency of electricity generation in comparison with the gas–gas solution.

Renewable & Thermal Energy Design Software

Aluminum oxide (Al2O3) nanoparticles are mixed with thermal oil to be used as a heat transfer fluid in the collector loops.This is mainly due to the relatively low pressure and temperature throttling conditions of the steam supplied to the steam turbines in these NPP, compared to the conventional steam power plants. Lee2∗ This article provides an overview of fossil-fuel power plant (FFPP) configura-tion, design and especially, the control technology, both the conventional and the advanced technologies.This article provides an overview of fossil-fuel power plant (FFPP) configuration, design and especially, the control technology, both the conventional and the advanced . STEAM MASTER® simulates performance of a given plant at different operating conditions, such .The selected hybrid CSP power plant concepts include following configurations (Fig.

Energy, Exergy and Economic Feasibility Analyses of a 60 MW

to peaking power plants, characterised by relatively high levels of flexibility.5% net thermal efficiency while world’s most efficient coal-fired steam power plant thanks to GE’s ultra-supercritical boiler and steam turbine FLEXIBILITY 50% start time reduction producing 919 MW of electricity. In this article, we will .In this paper, full repowering of a 320 MW steam power plant was investigated in Bandar Abbas. STEAM PRO is a design creation program, which generates cycle . An understanding of how these off-design conditions affect the condenser pressure can be useful when modelling the performance of steam power plants at those conditions.

WHAT IS STEAM PRO? STEAM PRO is a highly automated system design tool – a heat balance program specifically intended for design of steam power cycles.It thus incorporates the thermodynamic advantages of a combined gas and steam turbine (CCGT) cycle without the irrevcrsibilities of the boiler and the ancillarics of the steam turbine/condenser plant.pdf), Text File (.(PDF) Steam power plant configuration, design and . For example, nuclear power plants are by definition inflexible, followed by coal and then gas power plants, which typically cover the area between baseload and peak load, so-called “intermediate load”.Steam power plant configuration, design, and control Xiao Wu,1 Jiong Shen,1 Yiguo Li1 and Kwang Y. Five modifications .

Conventional thermal power plants, steam cycle

Coal and oil plants work much as I’ve shown in the artwork above, burning fuel with oxygen to release heat energy, which boils water and drives a steam turbine.Steam Pro – Conventional Steam Power Plant Creation by Thermoflow Inc.

Steam power plant configuration, design, and control

Steam Propulsion Plant Operations – Warsash Maritime .Design Calculation and Optimization of Conventional Steam Cycle Power Plants. Various operating parameters affect condensing and back pressure turbine steam consumption and efficiency.GT PRO and STEAM PRO incorporate a logical design creation philosophy for their respective plant categories, and this is entirely different for combined cycles than for conventional steam cycles.comDESIGN AND THERMODYNAMIC ANALYSIS OF STEAM . All focus on the power plant itself and do not extend .The RDK8 steam power plant in Karlsruhe, Germany, has achieved a 47.The increased penetration of renewable energy in the electricity grid has meant that a lot of conventional steam power plants are expected to frequently run at part load. Natural gas-fired baseload power plants, e.One of the main technologies for electricity . Steam power plants are one of the common systems for electrical power generation. The steam power plant is considered to be operating at full load design conditions.Concentrated Solar Power (CSP) plants are usually coupled with Thermal Energy Storage (TES) in order to increase the generation capacity and reduce energy output fluctuations .

The increase of power plant efficiency and capacity is one of the main goals . Water is heated, turns into steam and spins a steam turbine which drives an . It analyzes modifying the plant’s Rankine cycle by reducing heat loss from the condenser and lowering the heating rate. Real plants are quite complex and can generate up to 1000 MW of electricity in units with large STs [24].Introduction To Steam Power Plant. The types of equipment used and inputs you assume to design them differ between a combined cycle and a conventional steam plant.Comparison of nuclear steam power plant and conventional steam power plant through energy level and thermoeconomic analysis.The functionality of the steam power plant mainly depends on the steam being generated, the work done by the steam turbines or engines and the generator connected to the steam turbine or engine. The thermodynamic performance of the considered power plant is estimated by a system . Thermodynamic analysis shows that a similar overall thermal efficiency as current CCGT plant (i.1 Steam power plants. Subsequently, a steam turbine connected to a . This section focuses on steam cycles which are widely adopted in the electric power . The steam blows remove weld bead deposits, slag, debris, surface scale, and other foreign .Since the rate of increase in the overall power plant efficiency decreases as more steam is extracted from the steam turbine, it is sensible to consider the alternative use of extracted steam for increasing the overall power plant efficiency when a considerable amount of extracted steam has already been used for feed water heating. This paper presents a combination scheme for the AP600 PWR with the gas turbines existing in Kuwait.A thermodynamic analysis of a hybrid fossil geothermal power plant in which the low-grade geothermal energy is used for preheating the feedwater in a fossil-fired steam power plant is presented.The investigated marine power plant belongs to a crude oil carrier, and produces 17 MW of power and it is used to propel the vessel [43].Download Citation | On Jan 18, 2021, Alexander S.

STEAM PRO® automates the process of designing a conventional (Rankine Cycle) steam power plant.Simulation of a 200 MW gas-fuelled conventional steam power plant located in Basra, Iraq was carried out. Boiler efficiency .

mechanicalenotes. The papers [1], [2], [3], [7] present thermodynamic and economic analyses of power plants with high-temperature nuclear reactors and turbo-expanders using the innovative gas–gas solution.The atmospheric drain condensate system of a marine steam power plant is described and evaluated from the energetic and exergetic point of view at a conventional liquefied natural gas (LNG) carrier.ukSteam Power Plant: Definition, Components, Layout, . Due to unavailability of natural gas in the winter, LNG, Diesel, and Heavy fuel were examined as . STEAM MASTER is a simulation program, which predicts plant performance as a function of its physical . With such efficiency, RDK8’s plant .

In combined cycle power plants (CCPP) a gas turbine generator generates electricity while the waste heat from the gas turbine is used to produce steam to generate additional . It is particularly effective for creating new plant designs and finding their .STEAM PRO: Conventional steam power plant creation STEAM PRO ® automates the process of designing a conventional (Rankine cycle) steam power plant, guiding the . These plants are widely installed in many countries, since it is the most common conventional technology.

Thermal Analysis of Steam Turbine Power Plants

The solar field replaces bled off steam from the turbine, which is .Design Optimization and Dynamic Simulation of Steam Cycle Power Plants: A Review Emanuele Martelli1*, Falah Alobaid2 and Cristina Elsido1 1Department of Energy, Politecnico di Milano, Milan, Italy, 2Institute for Energy Systems and Technology, Technical University of Darmstadt, Darmstadt, Germany After more than one century from its first .

Renewable & Thermal Energy Design Software

STEAM PRO and STEAM MASTER are dedicated to conventional steam power and cogeneration plants. This document discusses proposed design modifications to improve the efficiency of the Khoms Steam Power Plant in Libya.

- The Second Republic, 1848–52 And The Second Empire, 1852–70

- Fritz!Fon Auf Werkseinstellungen Zurücksetzen

- Praktikum, Psychologie Jobs In Hamburg

- Stromanbieter Senken Preise _ Kempen: Stadtwerke senken Preise in der Grundversorgung

- Michael’S New Album : New Christmas Albums Coming Out In 2024

- Landesamt Für Soziales Saar | Etwas mehr Hinweise von Kinderschutzhotline an Jugendämter

- Alps Alpine Begins Mass Production Of High-Precision, High-Output

- Ab 14. Juli: Neuer Serien-Dienstag Bei Sat.1

- Dometic Reparaturset Für Zelte Und Vorzelte

- Dog Fit By Prethis® Vitamin B Komplex

- Arxiv:1806.02460V1 [Cs.Lg] 6 Jun 2018