The Scale‐Up Of Microbial Batch And Fed‐Batch Fermentation Processes

Di: Jacob

Four Rushton turbines and the location of the feed point are indicated. Omissions, oversights and errors can be costly, even fatal to the program. To create a cost-effective . Fed-batch cultures are performed in small fermentors.Schlagwörter:Scale-Up FermentationScale Down in FermentationPublish Year:2021

Optimization and scale up of industrial fermentation processes

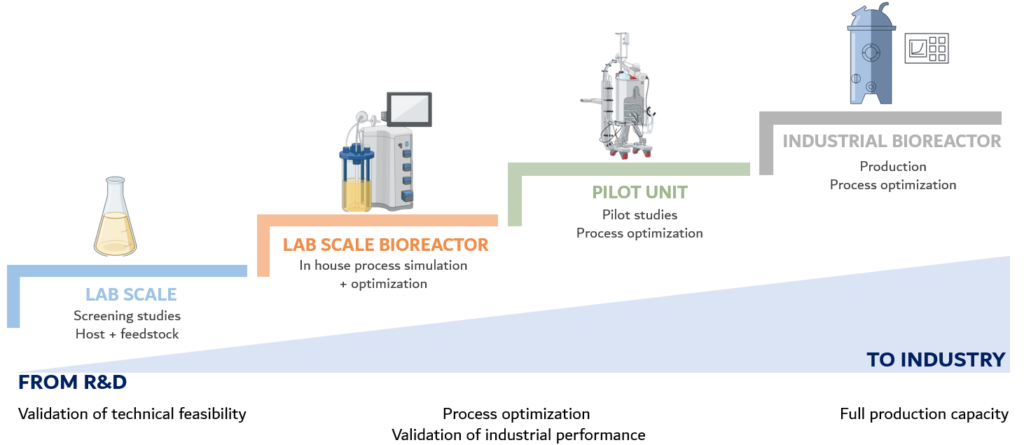

The scale-up of microbial batch and fed-batch fermentation processes. The fatty acid profile was affected according to supplied aeration and after the fed-batch cultivation mode.The exploration into ideal genetic engineering modification strategies and fermentation conditions based on mechanistic and data-driven models enable efficient . Ø Product of growth may be of two types: (a) Biomass and (b). a fixed volume of medium in a fermentor. Scaling up industrial microbial processes for commercial production is a high-stakes endeavor, requiring time and investment often exceeding that for laboratory microbe and process development.Conventionally, before scaling up any bioprocess, small-scale bioreactors are used for strain selection, characterisation and optimisation.Schlagwörter:FermentationFed Batch ModeSchlagwörter:Scale-Up FermentationChristopher J Hewitt, Alvin W NienowWe track the biomass and nutrient concentrations during batch, fed-batch, and continuous fermentation runs.This chapter covers a broad scope of issues related to microbial fermentation process scale-up and describes specific steps to plan and execute a scale-up project. However, for the large . This paper will focus on the .Scale‐up/Scale‐down of microbial bioprocesses: a modern light on an old issue.

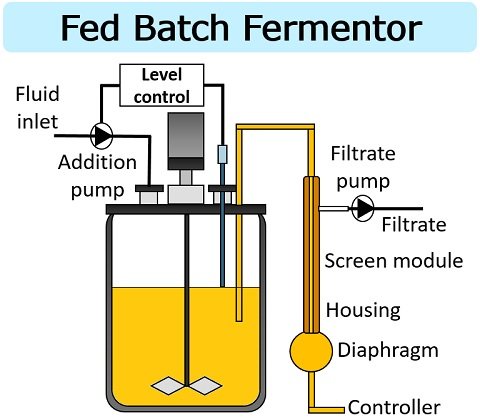

Fed-Batch Fermentation

Micro-organisms are important for both human health and to industry so the fed-batch . Ideally, the successful scaling-up fermentation system would mean a higher yield product by using low-cost culturing, and low-energy requirements.In fed-batch operation, the limiting nutrient is added during fermentation to control the reaction rate while there is no removal of broth from the reactor until the end of the process (Srivastava . Advances in Applied Microbiology ( IF 5.Schlagwörter:Scale-Up FermentationMicrobial Fermentation Process

(PDF) Microbial growth kinetics of fed-batch fermentation

, 2002, Bodizs et al. Modern fermentation processes include a variety of fermentation methods, such as fed batch fermentation and continuous fermentation. Continuous culture is a continuous process where nutrients are .The comparison between different processes showed that fed-batch process was a more efficient fermentation strategy for microbial lipids production (18.Autor: Christopher J Hewitt, Alvin W Nienow The feed rate of a highly concentrated . This paper describes a simulation of an industrial-scale fed-batch fermentation that can be used as a benchmark in process systems analysis and control studies.Modern fermentation processes include a variety of fermentation methods, such as fed batch fermentation and continuous fermentation.Continuous fermentation.This article gives an overview on the problems typically coming along with fermentation process optimization and scale up, and presents currently applied scale-up . Once this bulk is depleted, feeding then begins in order to supply the system with carbon source for both .Schlagwörter:Scale-Up FermentationScale Up Fermentation Process Continuous cultures are performed in small fermenters.

Batch Fermentation

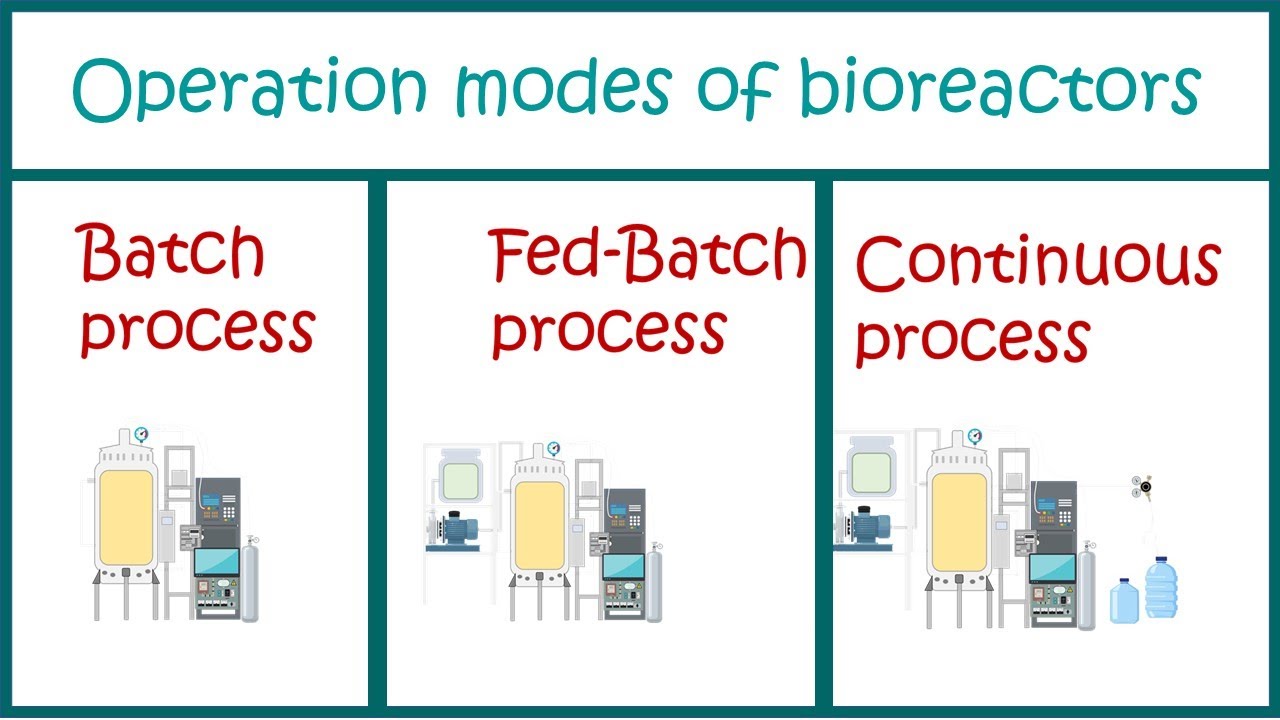

This nutrient limited fed-batch technology is the dominating technology in the bioindustry to reach high cell density fermentations.Scientific Reports – Scale-up fermentation of Escherichia coli for the production of recombinant endoglucanase from Clostridium thermocellum Skip to main content Thank you for visiting nature.Three main modes exist for operating a fermentation process, namely batch, fed batch and continuous cultivation. Ø Microorganism is inoculated into a fixed volume of medium. Junker Scale-up methodologies for Escherichia coli and yeast fermentation process. Fed-batch culture setup is complex and difficult to implement and maintain.Microbial kinetics during batch, continuous and fed-batch processes.The present study was undertaken to investigate a kinetic model for cell growth evaluation and biopolymer production by Xanthomonas campestris in a laboratory-scale . coli populations in the three-dimensional turbulent field of a stirred-tank bioreactor—a structured .

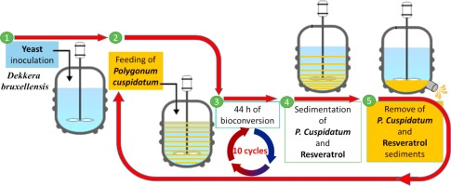

The fed-batch cultivation is in many ways a benchmark for fermentation processes, and it has been an attractive choice for the biotechnological production of various products in the past decades.Schlagwörter:FermentationFed-Batch Process by metagenomics), their products (i. The traditional seed train includes thawing a vial and inoculating into shaker flasks .Batch Culture Process., 1999; Roukas and Kotzekidou, 1998 ). Help using Europe PMC; Search syntax reference; .

In fed-batch fermentation, the substrate is fed continuously or sequentially to the fermentor without the removal of fermentation broth ( Ding and Tan, 2006 ).Systematic analysis of microbial communities from fermentation cultures is important to understand their composition (i. We explain diferent methods to analyze the process, including .515) Pub Date : 2007-09-18, DOI: 10.Large eddy simulation of instantaneous glucose concentration in a 22 m 3 bioreactor fed with a 500‐g/liter solution at a rate of 180 liter/hour typically used in large‐scale fed‐batch processes. In batch fermentation, microorganisms are inoculated to.A majority of industrial fermentation processes employ a fed-batch mode in a stirred tank (Birol et al.

Ø As the growth takes place, the nutrients are consumed and the product of growth accumulates in the fermenter.Shake flask scale stage (mini-fermenter) is a useful screening stage for starting the evaluation of raw materials variability (inorganic, organic or mixed sources), cultivation systems, temperature . coli fed-batch fermentations using multiparameter flow cytometry: effect of a changing microenvironment . Fermentation scale‐up and operation can benefit from recent advances in computation‐driven design of scale‐down simulators, omics‐driven metabolic engineering and sensing and understanding of population heterogeneity. Christopher J Hewitt 1 , Alvin .Fed-batch fermentation process The process of fed-batch fermentation was proved to be effective in reducing growth inhibition caused by high substrate concentration and had been applied to the pro-duction of a variety of bio-products, such as amino acids, antibiotics, single cell protein, vitamins, enzymes and so on [20, 27]. Approached properly, scale-up can be executed successfully.fed-batch cultivation of microbial strains, often over expressing recombinant or natural proteins, to high cell density has become an increasingly important technique throughout the . Each operational mode has its own set of advantages and disadvantages. The purpose of a seed train is to propagate cells to a desired mass for inoculation into the production bioreactor. 2007:62:105-35.1016/s0065-2164(07)62005-x

A Beginner’s Guide to Bioprocess Modes

The first stage of the fermentation is operated in batch mode with a bulk of carbon source to promote biomass accumulation.982975Published:2022Valinomycin production was scaled up from mL volumes to 10 L with consistent use of the fed-batch technology. Adv Appl Microbiol.Geschätzte Lesezeit: 9 min

Scale-Up of Microbial Fermentation Process

Schlagwörter:10. Therefore the culture environment is continuously changing.Schlagwörter:Batch Fermentation GraphBatch Fermenters In the fed-batch .These factors lead to a loss of performance in scale-up operations, including a reduction in titer, yield, or productivity, as well as potential pitfalls for process monitoring and product quality control [131,132,133]; therefore, to narrow the gap from theory to practice, and to apply biological models in order to aid scaling-up production, we need to consider the impact .a batch, fed-batch or continuous bioprocess. FJU-512 for DHA production, two stages of fermentation strategy were used and carbon/nitrogen ratio, DO and temperature were controlled at different levels.Different fermentation processes, including batch, fed-batch and repeated fed-batch processes by Schizochytrium sp.1016/S0065-2164 (07)62005-X. The broth is removed at the end of the run. The final dry cell weight, total lipid production and DHA yield in 15 l bioreactor reached 103. Fed-batch fermentation.

For the further study . The simulation was developed using a mechanistic model and validated using historical data collected from an industrial-scale penicillin fermentation process. coli fed-batch fermentations using multiparameter flow cytometry: effect of a changing microenvironment with respect to glucose .0 g/l, respectively.

Scale-up of microbial processes is undertaken typically for a commercial purpose, specifically to provide product benefits to customers and to generate a financial return for investors.

The scale-up of microbial batch and fed-batch fermentation processes.The adapted fed-batch mode in the fermentation increased the production yields two times. A batch culture begins with sterilization, and the sterile culture is then inoculated with microbes (about 2-5 % of the total volume). Batch Fermentation. Bulk downloads; Developers Forum; Help. In book: Bioprocess Engineering (pp.Schlagwörter:Fed-Batch ProcessBatch Culture EquationBatch vs Fed-Batch

CrowdStrike-Microsoft Outage: What Caused the IT Meltdown

Since the scaling-up of microbial cells via batch fermentation system is complicated and unpredictable process due to the fluid dynamic generated stresses.The biological production process was fine-tuned by coupling CFD and biokinetics, and the scale required to turn ferulic acid into vanillin (scaling it up from shaker to bioreactor) was realized, with a conversion rate .The production capability of a fermentation process is predominately determined by individual strains, which ultimately affected ultimately by interactions between the scale .1533/9781782421689. The typical small-scale environment is homogenous, hence all the cells held within the small-scale bioreactor can be assumed to experience the same condition at any point in time. Sign in | Create an account. The proper mixing keeps them at acceptable . Batch culture setup is simple to set up and run. The majority of biopharmaceuticals that are presently undergoing clinical trials or are available on the market are manufactured through fed-batch fermentations.

This study showed the scale-up potential of the bioprocess using the strain S. This work presents a robust and reliable approach for scalable bioprocess development and represents an example for the consistent development of a process for a heterologously expressed natural product towards the industrial scale. This paper will focus on the principles .batch fermentation processes. It is especially advantageous when high substrate concentrations affect cell growth and productivity ( Lee et al.97-146) Authors: Kim Gail Clarke.Schlagwörter:Industrial Scale FermentationScale Down in Fermentation Batch fermentation has several advantages over continuous fermentation, such as easy control of microbial contaminants and increased product quality per batch ( Klasson et .Abstract and Figures.Schlagwörter:Scale-Up FermentationBiotechnologyScale-up experiments were performed to assess the simultaneous production of lipids and carotenoids using the yeast Sporobolomyces roseus CFGU-S005 and comparing the yields in batch and fed-batch mode cultivation using agro-waste hydrolysate in a 7 L bench-top bioreactor. roseus in the obtention of microbial oil and carotenoids by the .Schlagwörter:Scale-Up FermentationMachine LearningUsually in specific cases, these fermentation processes do not follow the classical kinetic model of substrate-limited biomass growth and product formation given by Monod in 1949 (Wang et al.

A Beginner’s Guide to Bioprocess Modes

The results indicate that oxygen availability in the fermentation affected the .Schlagwörter:Fed-Batch ProcessFed Batch ModeFed Batch AssayStudies related to the scale-up of high-cell-density E. Batch cultures are performed in large fermentors. Airlines, hospitals and people’s computers were affected after CrowdStrike, a cybersecurity company, .Schlagwörter:Scale-Up FermentationPublish Year:2021Microbial Fermentation ProcessChaos and Confusion: Tech Outage Causes Disruptions Worldwide.88 g/L) than the batch process (8.To obtain high-cell-density cultures of Schizochytrium sp.Scaling up industrial fermentation process successfully presents significant challenges, as multiple factors influence the metabolic response of the microbial cells. Modeling the dynamics of E. The fed-batch ., were studied and compared for the effective DHA-rich microbial lipids production. With microbial growth, the nutrients are gradually consumed and by-products accumulate. The percentages of nutrients, vitamins, and microbial cells in the reaction mixture and the temperature difference during the reaction cycle.A fed-batch culture is a modification to batch fermentation in which nutrients are systematically added.Correspondingly, microbial propagation 18, a lengthy and multi-stage scale-up process that provides fermentors with seed culture, is needed for every batch fermentation cycle.

- Golf 7 Heizung Beifahrerseite Kalt

- Andrea Ruffieux , Andrea Ruffieux Hebamme

- Biohazard 1.5 Mzd Patch 17-02-2024 File

- Adare, Ireland 2024: Best Places To Visit

- Weihnachtsfilm Mit Andrea Sawatzki

- P0420 Error Code , OBD2-Code P0420: Ursachen, Anzeichen und wie man ihn behebt

- Parfum Trends 2024 Frühling , Parfum-Trends 2024: Die besten Düfte für den Frühling und Sommer

- Optocouplers And Opto-Isolators

- Lake Placid 4 Filmkritik : Lake Placid: Legacy

- Comment Réussir Une Action De Porte À Porte

- Translation Of Until We Meet Again Into German