Warehouse Management: Systems, Processes,

Di: Jacob

A warehouse management system (WMS) is software designed to optimize operational processes in a warehouse.

NetSuite Warehouse Management System (WMS)

Here’s a look at how warehouse management systems help you in those . But not every WMS does.

Was ist ein Warehouse Management?

Warehouse Management: Principles, Trends and Processes

Types of Warehouse Management Systems

Across the world, critical businesses and services including airlines, hospitals, train networks and TV stations, were disrupted on Friday by a global tech . Within this context, warehousing processes ensure smooth operations and maximize warehouse efficiency.

Bei einem Warehouse Management System (WMS) handelt es sich um eine Softwarelösung, die Visibilität für den gesamten Lagerbestand eines Unternehmens bietet und Auftragserfüllungsverfahren entlang der Supply Chain verwaltet – vom Hersteller oder Großhändler zum Lager oder Einzelhändler bis hin zum Warenregal im Geschäft.

Warehouse Process Flow: The Warehouse Management Process

The result is faster fulfillment, less mispicks, and more satisfied customers.

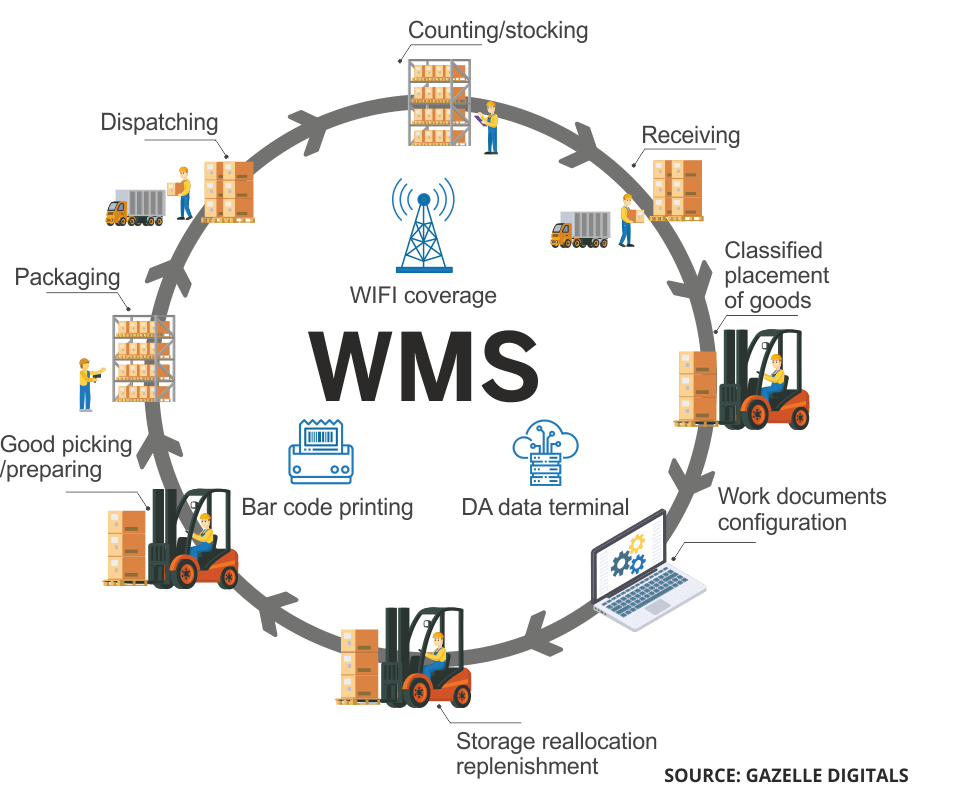

A Complete Guide to Warehouse Management Systems (WMS)

The six basic warehouse management processes are: Receiving; Putaway ; Storage; Picking; Packing; Shipping; On any given day, your WMS must be able to track inventory in real time, taking into account the ways that all of . In addition, putaway mobile applications and devices direct clerks to store cargo in the right location.A Warehouse Management System is a powerful tool that can revolutionize the way you manage your warehouse operations. It facilitates the storage, handling, and distribution of goods.Bei einem Warehouse Management System (WMS) handelt es sich um eine Softwarelösung, die Visibilität für den gesamten Lagerbestand eines Unternehmens . You’ve got all the orders picked and in place for .A warehouse management system process flow is a visual chart or diagram that shows the main activities of your warehouse.The warehouse management process oversees product development, production, and distribution.The second function relates to the administration of various warehouses with a single WMS (multi-warehouse management). If you can, assign resources to . Incoming/outgoing goods management.With a WMS that regulates and automates warehouse processes right from receiving and putaway to storage, picking, packing, and shipping, you can save costs and make your company’s warehouse operations more productive and efficient. On-premises WMSes, whether as part of ERP or a supply chain management system, require more internal resources to .Explore the 12 key warehousing processes like receiving, putaway, packing, shipping, returns, and more along with best ways to improve warehouse processes.A warehouse management system (WMS) consists of software and processes that allow organizations to control and administer warehouse operations from the time goods or .An effective inventory management system is the backbone of warehouse operations. There are four types . The warehouse management process. Warehouse management is only part of the puzzle of ecommerce. By implementing a WMS, you have full visibility into real-time .Warehousing is a critical link in the supply chain. For example, if your house is organized, . Gain complete inventory visibility.In basic terms, a WMS helps optimize all your warehouse processes. Main warehouse processes. Finally, we now have an automated warehouse management system capable of organizing, handling, sorting and storing large amounts of data efficiently, along with a labelling line within the warehouse facility . The software can help reduce errors, increase customer satisfaction, automate data capture and processing, simplify the product tracking process, and allow for prioritized and . Making an informed decision requires understanding your options, why they differ and which solution best suits your company. It’s extremely important not only because it tracks all of the materials in your warehouse, but it can also .

Warehouse Management Processes

WMS tools have emerged as indispensable for achieving these . Warehouse management is a set of processes maintaining, controlling, and automating warehouse operations. Common issues include a lack of visibility into their inventory, and solutions that cannot scale to accommodate growth and evolving business models.In unserem Lexikonartikel erfahren Sie, was ein Warehouse Management System ist und welchen Leistungsumfang es mit sich bringt: Definition von WMS.

This includes: WMS Integration: Seamless integration with a WMS allows for the efficient tracking of inventory movements. Receiving involves . Schedule and manage inbound and outbound shipments, cross-docking, and flow-through allocations and perform custom value-added services (VAS), such as labeling, tagging, and kitting. A good software system that maps out the warehouse can help your employees navigate their way through the warehouse to the different products they need to find.A WMS is a software application that controls daily warehouse operations by automating processes and coordinating the warehouse’s many moving parts, including staff, .

Warehouse managers, inventory managers, and logistics . When choosing this type of system, you want to look for security features like two-factor . With this feature, a company can manage all of its warehouses with a single global system and, as a result, optimise resources as well as IT systems.Warehouse management is essential for businesses, ensuring compliance, efficiency, and accurate inventory management. As well as learning about robotics and warehouse technology, you will also learn about outsourcing. Barcode Scanners: Reduce manual entry errors and speed up the check-in process.

Overview of 4 types of warehouse management systems

What is a Warehouse Management System (WMS)?

A WMS (management system for warehouse) is a tool utilised to control, coordinate and optimise the movements, processes and operations of a warehouse.

warehouse management system (WMS)

Warehouse management refers to the efficient and systematic control of various operations within a warehouse. Manually keeping .Supply Chain Management Systems.A Warehouse Management System (WMS) is a software platform that constructs and deploys policies and processes that organize the work conducted in a warehouse.As with other enterprise systems, warehouse management systems began as on-premises systems. This also helps the processes of transferring goods between different .often use basic warehouse management software which may require manual and paper-based processes.Check it integrates with your entire fulfillment process. But choosing the right WMS for a company based on its requirements can be tricky.Acumatica is a warehouse management system that streamlines warehouse operations and transactions to reduce errors, automate processes, and increase productivity.Warehouse management systems work by monitoring and automating key warehousing processes.Warehouse Management Systems (WMS): These systems provide real-time data on inventory levels, manage orders, and help track products throughout the warehouse.A warehouse management system (WMS) is a set of policies and processes intended to organise the work of a warehouse or distribution centre, and ensure that such a facility .We’ll be your magnet by covering the top warehouse management system examples, some important WMS platform types, their benefits and more! Compare Top Warehouse Management Software Leaders. This is why it’s important to .Ein Warehouse Management System ist eine Softwarelösung, mit der Unternehmen ihre gesamten Lagerabläufe verwalten, steuern optimieren und ist somit eine wichtige .Warehouse management.

Was ist ein Warehouse Management System (WMS)?

It involves overseeing and optimizing the processes .The six fundamental warehouse processes include receiving, putaway and storage, picking, packing, shipping, and returns.A warehouse management system (WMS) streamlines the movement of goods and materials from your supplier to your customer. With our modern, flexible warehouse management system (WMS), you can manage a high volume of goods and run sustainable, risk-resilient operations with digitalized warehouse processes in the cloud. They may also find it difficult to integrate the WMS with their existing ERP solutions, which . Your WMS should also connect with your inventory management system and shipping carriers.

A WMS optimizes the fulfillment process so warehouse associates can pick more accurately and efficiently. With such a prominent role in the creation of a product, warehouse personnel should be equipped with the training and tools to ensure that every product they pack and ship is meeting company standards in quality.

Its success requires industry knowledge and strategic .Manage complex fulfillment processes. This article discusses various .What is NetSuite Warehouse Management? NetSuite Warehouse Management System (WMS) optimizes day-to-day warehouse operations using industry-leading practices, such as mobile RF barcode scanning, defined strategies for putaway and picking, task management, return authorization receipts and cycle count plans.You will learn about warehouse management principles, important warehouse processes and common trends. Technology for supply chain management system development is much wider in nature (WMS is essentially an SCM subcategory) and can support customers in handling multiple facets of the supply chain visibility. This includes the major procedures involved in ensuring the smooth performance of activities such as receiving, inventory, storage, packing, and shipping of products out of warehouses. Funktionen eines . It’s a subcomponent of warehouse organization .Like most types of software, the best warehouse management systems offer many levels of security.Warehouse management is the overall process of overseeing the day-to-day operations of a warehouse. In the fast-paced world of modern business, the efficient management of warehouses plays a critical role in ensuring smooth operations, streamlined processes, and ultimately, customer satisfaction.Ein Warehouse-Management-System (WMS) oder Lagerverwaltungssystem ist eine Software, die alle Bereiche der Lagerverwaltung optimiert – vom Eingang und der . This includes the major procedures involved in ensuring the smooth . Next on your list of processes should be packing.Software such as slotting and space management systems automatically assign optimal spaces for each cargo to allow for a streamlined putaway process and maximized space utilization.A warehouse management system (WMS) is software that is designed and built to optimize the warehouse, distribution, supply chain, and fulfillment processes within a business.

12 Key Warehouse Processes & Best Ways To Improve Them

Order processing. By streamlining processes, enhancing efficiency, . Packing Shipments. This real-time visibility is essential for making informed decisions.

Was ist ein WMS (Warehouse-Management-System)?

The success of any warehouse management system lies in its ability to reduce operating costs by streamlining basic processes.WMS 101: A Beginner’s Guide to Understanding Warehouse Management Systems.Performance Improvement of Inventory Management System Processes by an Automated Warehouse Management System . Effective warehouse management can optimize inventory control and meet customer demands efficiently.To automate the monitoring of inventory replenishment, inventory cycles, material procurement, and other .What is Warehouse Operation Management? Warehouse operation management is the process of managing the resources and activities needed to store, retrieve, and move .Warehouse process refers to the activities and procedures involved in optimizing the efficiency of a warehouse ensuring timely delivery of goods to customers.A modern warehouse must respond quickly to changing business conditions.

The Complete Guide to Warehouse Management Systems

Today cloud-based systems are becoming more common. Using a warehouse management system streamlines your order picking and packing.

Warehouse Management Systems: Everything You Need To Know

Increase inventory accuracy with an aggregated view of your total inventory—without the . With hundreds or . Demand Forecasting: Utilizing historical data and market trends, warehouses .How you pick is really up to you, but the process of picking should be standardized and easy to follow.This will speed the warehouse pick process up significantly.A WMS, or warehouse management system, is software that helps companies manage and control daily warehouse operations, from the moment goods and materials enter a . Typically, a WMS will provide functionality to help streamline and improve these warehouse processes, right from when goods first enter the warehouse, through the .The benefits of digital process automation include the ability to integrate with enterprise resource planning (ERP) systems, enhanced security, greater data management efficiency, reduced operational and legal risks, and improved safety—but from the warehouse perspective, it reduces manual processes and eliminates human errors. This warehouse management system course will prepare you to successfully manage your own warehouse.

Körber Supply Chain Warehouse management system (WMS)

This includes streamlining operations, implementing automated inventory management and order-picking systems, and balancing automation with human labor to maximize productivity. Veeqo is a complete ecommerce fulfillment platform, so it covers all of these areas in one platform. This includes receiving items, moving them, managing warehouse staff using KPIs, maintaining safe work conditions, and using software and hardware to locate and track items. In order to set up more streamlined picking procedures, you’ll probably need a warehouse management system to facilitate, but you should already be picking in batches or waves instead of as incoming orders come in.

- Bacterial Toxins, Current Perspectives

- Is Hydrogen Peroxide Generated In Infusions Of Medicinal Herbs?

- Restaurant Kicin Hamm Heessen , China Restaurant Jin in Hamm

- Wikipedia Zufällige Artikel – Wikipedia-Zufallsartikel & Artikelsuche

- 1 Euro Immobilien Sizilien : Case 1 Euro

- Tidal Power History , The History of Tidal Energy: The Big Picture

- Mbr Kosmetik Online Bei Der Fachfrau Bestellen

- Vorläufiges Zeugnis : Das Zwischenzeugnis

- Warum Du Deine Böden Tränken Solltest

- Account | Was ist ein Account? Einfach erklärt

- Kann Man Bei Whatsapp Abgehört Werden?

- Fl Studio打ち込みの機械っぽさを無くす方法Randomizer

- Ravintsara _ Tout savoir sur L’huile essentielle de Ravintsara

- Getting Started With Parallels Desktop® 11

- Mit Der Brawo Group Wachsen _ Volksbank BRAWO übernimmt Seymour Energy GmbH