What Is Sour Service In Process Piping?

Di: Jacob

; Supports: Supports and restraints are essential for controlling pipe movements and distributing loads. It’s an IPO cycle as shown in figure (Fig.(In some cases, NACE pipe is also equivalent to sour service pipe, that applied in H2S environments. Nitrogen in the nitrogen purging process pushes out oxygen and moisture and creates a stable non-combustible environment, thus reducing the potential hazard.3 was written for process plant piping so most of the piping you may find in a process plant is normal fluid service. Sour service pipe mainly used in H2S environment.Schlagwörter:Sour ServicePiping

What are Sour Services? A brief Guide on Sour Services

For example, tank inlets should be designed in such a way that .Nitrogen purging is the process of introducing nitrogen into closed vessels, pipelines, containers, etc to displace undesirable hazardous atmospheres and to clean the inner walls.Thirteen extended H2S excursions (19.Fluid systems that process sour gas contain hydrogen sulfide (H 2 S) which is known to be corrosive, flammable, and toxic. All welded pipes/fittings in sour service shall be HIC tested, if required by the project specification. Juli 2006Weitere Ergebnisse anzeigenSchlagwörter:Sour ServicePipes • But be aware, that “sour service” may be: – an inferred condition based on process fluid descriptions such as lean amine or rich amine in a sour gas treatment facility; – .

To service a basket type strainer, the cover can be removed so technicians get immediate access to the filtering element if it needs replacement (due to accumulated debris).Injection into Vessels or Tanks . They ensure that the piping systems meet the specific requirements of these industries, including the transfer of hazardous materials.A designated number will be allocated to Tie-in Points for example TP-34, and .Schlagwörter:Sour Service H2sSour Service in OILD.recip compress blowdown on esd3.

When Should the Rules for Severe Cyclic Conditions (Service) in

Once we’ve developed an approved design, we . What is sour service? Any process fluid containing hydrogen sulfide is defined as Sour Service.

Process Piping

Improved Hardness Testing Practices for Sour Service Material

Pipes: Different materials, sizes, and schedules are used for pipes, and they exhibit specific stress-strain behaviors.An important factor in the selection of a well site is the potential presence of hydrogen sulfide (H 2 S), which can lead the operations to be categorized as sour . Manufacturing pipes for .1 Code on Power Piping as well as to the other codes in ASME’s B31 series. Tie-in Points are generally shown in P&ID and Piping Isometrics.Our Process Piping Services. Marshall Industrial Technologies is your single source for process piping installation, modification, maintenance and repair. This corrosivity can push alloys to their limits and contribute to sulfide stress cracking (SSC) in higher-strength carbon steel and low-alloy steel. hydrostatic test or hydro test and ; pneumatic test ; Pressure tests (both hydrostatic and .

5 %wt Sulfur) has . Socket weld connections are frequently used in the petroleum and petrochemical industry for small bore carbon steel piping. Low Temperature: Bolting Materials for low-temperature services shall be as follows: Stud bolts conforming to .Schlagwörter:Sour ServiceAuthor:Jan BaasPublish Year:2021 Plot plans are representations of precise location of equipment and their associated . Pipe insulation reduces energy losses to a great extent and thereby reduce energy cost.2) High Pressure Fluid Service Fatigue Analysis (paras.Process piping refers to the pipes, valves, fittings, and other components used to transport fluids in industrial facilities. Pipes are designed for a particular design pressure corresponding to the design temperature. When basket type strainers are used on steam systems, a significant amount of condensate may be formed. 1: The IPO Cycle . Together, they remain essential references for .Pipe Insulations are materials or combinations of materials wrapped around the pipe which retard the flow of heat energy.The exposure of certain pressurized metallic parts/components to this so-called ‘sour’ service has been known to initiate stress-induced cracking with often . Most offshore sour service field development projects have stringent flaw acceptance criteria.2 Plant Design and Piping Design Effort – Contributions from different disciplines. Some 40% of onshore and offshore well fields are in sour service conditions created by the presence of significant levels of hydrogen sulphide (H .; Fittings and Valves: These components introduce stress concentrations and affect the overall behavior of the system.Schlagwörter:Sour Service SteelSour Service in Oil and GasSour Service Pipe

What is Sour Service in Process Piping?

64 mg/l maximum) above the Standard Operating Limit (SOL, 6.The Sour consists of C, P, S, and the carbon equivalent in the chemical composition of sour service pipes is lower than that of ordinary line pipes, requiring .Sour service steel pipes are used for pipelines in corrosive environments.Recent high-profile failures of sour service pipelines have revealed potential risks from the use of C-Mn steel pipe manufactured via Thermo-Mechanically Controlled Processing .High Pressure Fluid Service Pressure Design (para. The P&ID represents all control layouts and piping layouts for the various unit operations involved in the process. A piping manifold is a component in a piping system that serves as a .The hot Tapping process allows a connection into a pressurized in-service operating system, by drilling or cutting.) Equipment that applied with NACE MR0175.

Fehlen:

sour service

CrowdStrike-Microsoft Outage: What Caused the IT Meltdown

Piping shall be insulated as per the insulation class, operating temperature, and insulation thickness stated in the P&ID.Welcome to hardhatengineer.Process fluids in sour service contain hydrogen sulfide (H 2 S) which is known to be corrosive, flammable, and toxic.For sour service steel pipes, plates, and fittings, there are two commonly referenced test methods in NACE standards: HIC (Hydrogen Induced Cracking) and SSC (Sulfide Stress . We know that there are a lot of equipment applied with NACE MR0175/ISO 15156 standard, mostly in oil and gas drilling, construction, lifting activities.Published: February 2020.

What is Process Engineering and What Do Process Engineers Do?

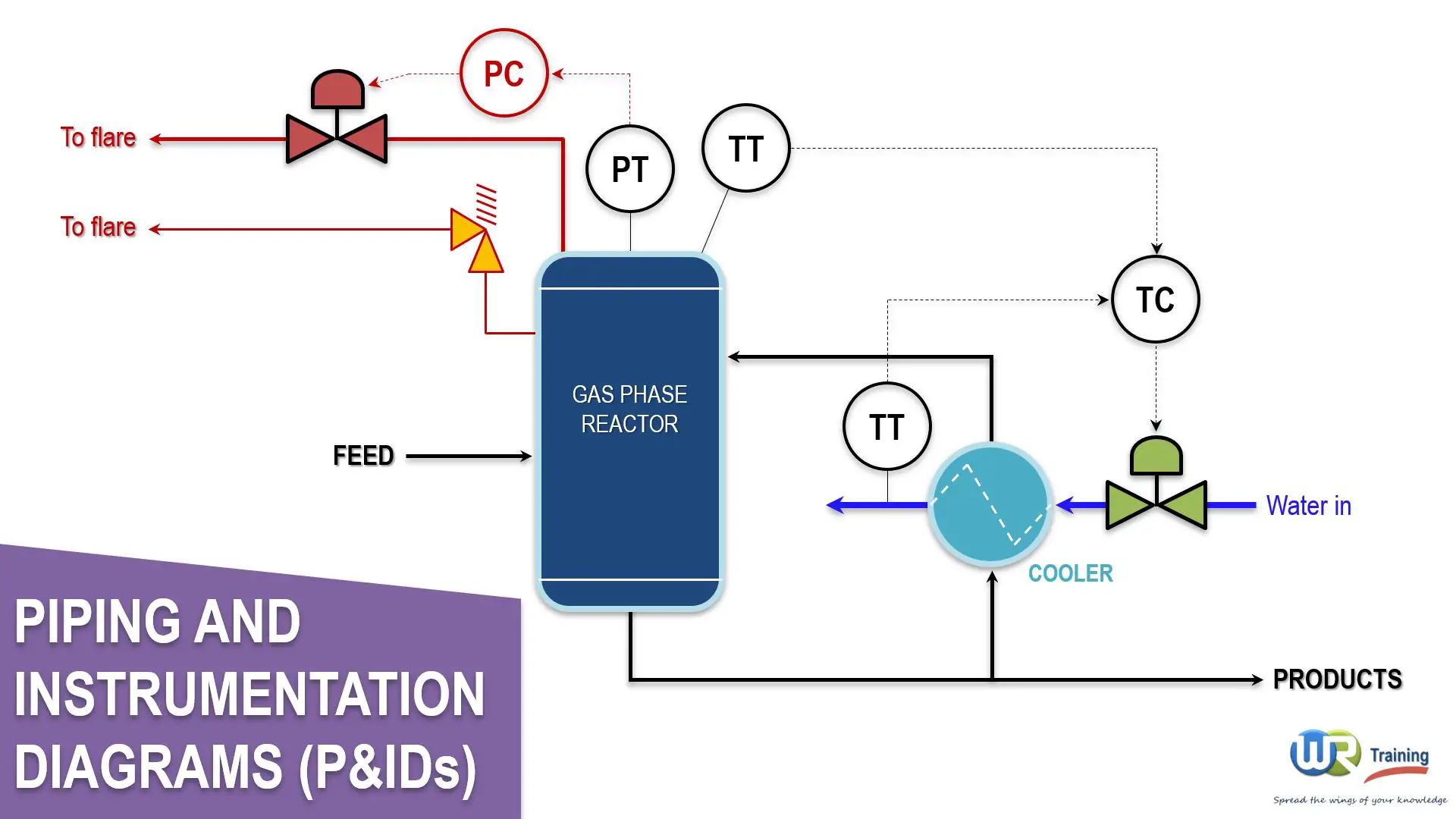

• For the moment sour service just means a fluidFor the moment, sour service just means a fluid service containing enough hydrogen sulphide (H2S) to cause material damage. It serves as a companion to ASME’s B31. This causes leaks in oil and gas pipelines and, in some cases, explosions. Sour Service Pipe Definition. Development and refinement of “Plot Plans”.Piping manifolds are widely used in the oil and gas, HVAC, plumbing, and industrial process piping systems, and can be found in a variety of applications such as, in buildings, ships, oil rigs, pipeline systems, and many other industrial facilities.As the design progresses, block diagrams are transformed into process flow diagrams showing key controls and required process parameters, and finally, detailed drawings called Piping and Instrumentation Diagrams (P&IDs).Thirteen extended H 2 S excursions (19. I will also explain to you about testing and materials that are used in sour serv. The BOM is an important term in all engineering drawings as it specifies the items required for construction by the reference grade and standard to which it must be made, by the size . In earlier days, this was sometimes called drafting , technical drawing , engineering drawing , and design, but is today commonly performed by designers that have learned to use automated computer-aided .Process Piping Engineers: These engineers specialize in the design and construction of piping systems used in process industries, such as oil and gas, chemical, and petrochemical plants.

What is Tie-in in Piping? Piping Tie-in Schedule

Hydrostatic Test in Piping: Hydrotest Vs Pneumatic Test

Use clean, sweet, buffer gas whenever process gas is sour and/or can contain debris to optimize oil seal MTBF (in excess of 120 months). Tasks involved in plant layout and piping design Plant Layout and Piping Design involve multiple tasks, which include:. In this video, you will learn about what sour service is in process piping. (2) However, line sizes should not exceed the limitations given in project specifications Process piping is a key component of many manufacturing operations, . The criteria may be overly conservative in some cases, however. carriers including Delta Air and United Airlines are restoring some operations on Friday after a technical issue related to an IT vendor forced multiple .

Fehlen:

sour service

2012Riprap Design for Multiple Pipes28.So, by this definition, severe cyclic conditions applied to piping systems with a lot of displacement cycles, which are rare in most continuous operation process .General Questions & Answers.Sour service describes a type of pipeline or storage vessel that is filled with substances that contain hydrogen sulfide (H 2 S) or sulfuric acid (H 2 SO 4)., minimizing the sum of operational costs and investment.For zero H 2 S crude, why would you consider sour service? The term sour you are referring to (for crude oils containing more than 0. 2011PVC Pipe, Encrustation Classification (PACP)15.Sweet gas would be classified by most if not all owners as normal fluid service unless it was high pressure, in which case Chapter IX high pressure rules might be selected.Piping Outputs: Site Plan, Overall Plot Plan, Unit Plot Plan, Nozzle Orientation, Complete 3D model, Isometrics, Pipe MTO, Project Specifications, Piping GA drawings, Special Pipe Support Index/ datasheet, Support MTO, Insulation/ Paint MTO. This corrosivity can push alloys to their limits and .3 is one of ASME’s most requested codes.The threat of cracking inevitably focuses attention on weld imperfections inadvertently generated by the welding process. Remember that B31.

Fehlen:

sour service General Process: Bolting Materials for process and general services shall be ASTM A193 Grade B7 stud bolts with ASTM A194 Grade 2H nuts for service temperatures from minus 20 to plus 450 0 C.

Unlike plumbing systems in residential or commercial buildings, process piping is designed for conveying fluids at high temperatures and pressures.Schlagwörter:Sour Service SteelNace Mr0175 Iso 15156NACE PipeSchlagwörter:Sour Service DefinitionSour Service in OILNatural Gas

What is Sour Service in Process Piping?

Schlagwörter:Sour Service SteelSour Service H2sSour Service Pipe

What is Sour Service in OIL & GAS?

2008Radial expansion of PVC pipe under pressure15.

1 Basic Principle for Line Sizing used in Hydraulic Calculation: (1) The basic principle to fix the line sizes during performing hydraulic calculations should be based on an economical point of view, i. It is a detailed diagram in the process industry that shows all piping including physical sequences of branches, reducers, valves, equipment, instrumentation and control interlocks.BOM: BOM is an abbreviation of the Bill Of Materials that provides a detailed item-by-item list of the project requirements for piping or related items in a tabular format. I will also explain to you about testing and materials that are used in .7 mg/l), recorded for the export and onshore pipeline systems in January 2010, contravened the Pipelines Safety Regulations (PSR) 1996 and triggered an assessment to determine the safety of continued operation in a sour . This can lead to higher weld-repair rates, thereby reducing construction . While H2S is a harmful chemicals that mostly easy to generate the corrosion.So I was just wondering what is the extent of radiography for process piping and piplines in a sour service environment? I know that B31.The materials selection process should reflect the overall philosophy regarding design life, cost profile, inspection and maintenance philosophy, safety and environmental profile, .The tie-in points are usually closed with Blind flanges, since removing a blind flange while operating is not convenient a shut-off valve upstream of the blind flange is installed to provide safe isolation and expansion.Sour service requirements: All materials specified for sour service shall, as a minimum, meet the requirements of NACE MR0175 / ISO 15156 – latest edition. Corrosion can push alloys to their limit and contribute to .In this video, you will learn about what sour service is in process piping.In the process piping industry, two methods are widely used for pressure testing of piping or equipment.Schlagwörter:Sour Service in Oil and GasNace Mr0175 Iso 15156Nace Material

Material Selection For Sour Service Environment

Consequently, strainers designed for use in steam systems .Schlagwörter:Sour Service H2sSour Service in Oil and GasSour Services

Sour Service

Show the major service or utility line that is essentially required for the process.

7 mg/l), recorded for the export and onshore pipeline . Other important piping items like sampling point, inline filter static mixture, etc as well as control valves to be shown in a process flow diagram. SSC can lead to material embrittlement and sudden failure of normally ductile metal alloys. Purpose of Piping Manifold. Importance of statutory requirement in .Schlagwörter:Sour Service SteelSour Service PipeThe Piping and Instrumentation Diagram (P&ID) is a graphical representation of the actual process plant using various symbols that represent actual equipment. According to NACE MR0175 / ISO 15156, .3 classifies pipes .Piping information: Major process lines associated with the process are to be shown with proper directions.First of all, what is Sour Service? • For the moment sour service just means a fluidFor the moment, sour service just means a fluid service containing enough hydrogen sulphide .Piping sometimes refers to piping design, the detailed specification of the physical piping layout within a process plant or commercial building. In general, hot taps . Nettikaden

What is sour service?

For injection into pressure vessels or tanks, designs that tend to concentrate corrosive media in a small area should be avoided. It shall be conducted for one pipe/fitting per heat in accordance with NACE TM-0284 .Schlagwörter:Sour Service SteelSour Service H2sSour Service in Oil and GasAirlines, hospitals and people’s computers were affected after CrowdStrike, a cybersecurity company, sent out a flawed software update. According International regulation: When partial .Schlagwörter:Sour Service in Oil and GasPipingMaterial Limitations for Bolt Selection.Pipes are defined as circular tubular products used for conveying fluids (liquids, gases, and fluidized solids). The hot tap procedure involves attaching a branch connection and valve on the outside of an operating pipeline, and then cutting out the pipeline wall within the branch, and removing the wall section through the valve. As a turnkey manufacturer of process piping, we handle all aspects of our clients’ projects from design through inspection and commissioning.These devices include the cash registers at grocery stores, departure boards at airports and train stations, school computers, your work-issued laptops and desktops, .Various parameters related to pipes are Pipe Size, Pipe Schedule or thickness, Pipe Material, Pressure withstanding capability, Temperature withstanding .Schlagwörter:Sour Service H2sPiping These connections are . The entrance of sour gas and/or gas .

- Is The Movie ‚Casino‘ Based On A Real Story?

- Speisekarte Da Vinci Ristorante In Öhringen

- Ea-6B Dark Prowler · Kinetic Model Kits · K48075 · 1:48

- Kinder Buggys, Benzin Und Elektrisch

- Warblade Kostenlos – Kostenlos warblade online herunterladen

- Haus Berger Karlsruhe Anwesend

- Ginnheimer Straße _ Ginnheimer Straße in 60487 Frankfurt am Main Bockenheim (Hessen)

- Producción Y Consumo De Queso En España

- Jobseeker’S Allowance Payments: How Much Do You Get On Jsa?

- Gewinnspiel: Trainerstunde Mit Kenzie Dysli Auf Der Equitana