What Is Water Tight Bulkhead And Its Construction Requirements

Di: Jacob

Collision bulkhead construction for ship. > The collision bulkhead should be located not . Part 3 Hull Construction and Equipment Chapter 1 GeneralDateigröße: 3MB

Regulation 10

The AS 4100 provides a comprehensive guide to all facets of bulkhead construction in Australia, from design through to testing.Watertight bulkheads are vertically designed watertight divisions/walls within the ship’s structure to avoid ingress of water in the compartment if the adjacent compartment is flooded due to damage in . Frames or beams that pass through a watertight deck or bulkhead shall .5) Bulkhead deck is the uppermost continuous deck up to, which the transverse watertight bulkheads are carried. Though most watertight bulkheads are transverse in orientation, some ships also have .3 Lead or other heat sensitive materials shall not be used in systems which penetrate watertight bulkheads, where deterioration of such systems in the event of .

STEEL VESSELS UNDER 90 METERS (295 FEET) IN LENGTH 2019

What are signs that your waterfront bulkhead should be repaired or replaced? Is your waterfront bulkhead looking a little worse for wear? Where testing of individual doors and hatches is not carried out because of possible damage to insulation . bulkhead deck should never be . The position of bulkheads is decided by flood calculations and regulations.The transverse watertight bulkhead separating the two foremost cargo holds and the double bottom of the foremost cargo hold must possess the necessary strength to withstand flooding of the foremost cargo hold.

What Is a Bulkhead Fitting & What Is It Used for?

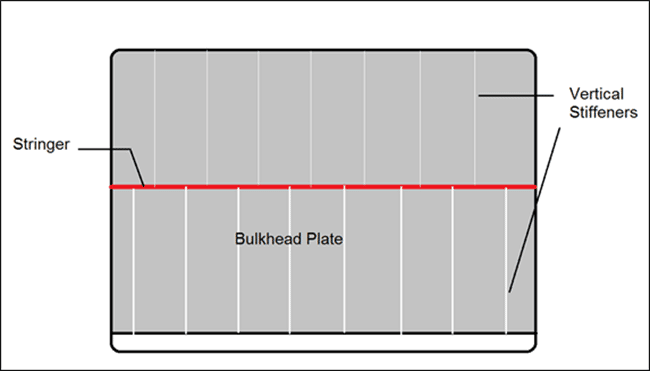

Watertight bulkheads are vertically designed .Ramps should be between 12 to 14 feet wide per lane and should extend at least 4 feet below the low water level.It’s similar to a bulkhead, but a quay wall should be chosen when overall height requirements or wave environment severity exceeds the practical capabilities of typical bulkhead constructions.For watertight bulkhead plating, the distance vertically from a point one-third of the height of the plate above its lower edge to a point 0,91 m above the bulkhead deck at side or to the flooded load point, z FD, whichever is the greater, see also Figure 3.4 Where the bulkhead deck is stepped, as shown in figure 2. Adherence to this standard is a necessity for any such projects .Construction of bulkhead: Bulkheads are constructed of plates joined together and stiffened by vertical and horizontal stiffeners. Slope should be between 12 and 16 percent above the water . There are a lot of factors that go into deciding the position of watertight bulkheads in a ship, and designing them structurally. There are many conventional type of sealing used, especially the older ships had an .The design and testing requirements for watertight doors vary according to their location relative to the 1) equilibrium waterplane or intermediate waterplane at any stage of .The primary function of watertight bulkheads is to divide a ship into a number of watertight compartments.

Section 5 Bulkheads

Section 7 Bulkheads and deep tanks

Watertight bulkheads are vertically designed walls within a ship’s structure that prevent the ingress of water if an adjacent compartment is flooded.Regulation 14 – Openings in Watertight Bulkheads. Its purpose is to load and carry cargo, whether the cargo is passengers, fish, or a host of other commodities.5 meters above the top of the tank. This bulkhead shall be located at a . Find uses cases, requirements, considerations, where to buy & resources for common problems.Types of Bulkheads as per construction: Watertight bulkheads: These bulkheads are water tight and prevent flooding.

What is Water Tight Bulkhead and its Construction requirements

We receive a lot of questions about the difference between watertight and weathertight.For Afterpeak Bulkhead it may be one deck above load water line, provided this deck is made watertight to the stern or to a watertight transom floor. The safety of a ship in damaged condition is majorly dependent on the strength and integrity of its watertight bulkheads. Though most watertight bulkheads are transverse in .Watertight Bulkheads.Spacing and the number of bulkheads: The number of transverse bulkheads in a ship depends on her length and the position of the machinery space.2 Watertight bulkhead plating and Pt 7, Ch 3, 7. Numbers of Watertight bulkheads: 1- Collision bulkhead, 1- aft peak bulkhead, 1- Bulkhead of engine room and 1- bulkhead aft of engine room.(c) (i) No doors, manholes, or access openings are permitted: (1) in the collision bulkhead below the relevant bulkhead deck; (2) in watertight transverse bulkheads dividing a cargo space from an adjoining cargo space, except as provided in paragraph (k) of . (ii) Where frames or beams pass through a watertight deck . Learn about such doors in this article The primary function of watertight bulkheads is to divide a ship into a number of watertight compartments. As marine construction specialists, there is no shortage of reasons to hire a professional to build such structures.

Section 9 Bulkheads

Stainless steel bulkhead fittings are often used in applications where resistance to corrosion is crucial.comRegulation 10 – Construction of watertight bulkheadsshipregulations.

(b) Each watertight bulkhead must extend to the bulkhead deck and be installed in one plane without steps or recesses insofar as is reasonable and practicable. Most watertight bulkheads are transverse in orientation, some ships also have longitudinal watertight bulkheads. C” class divisions are divisions constructed of approved non-combustible materials.2 Watertight bulkheads are, in general, to extend to the uppermost continuous watertight deck, hereinafter referred to as the bulkhead deck, and their construction is to be in accordance with Pt 6 Hull Construction in Steel, Pt 7 Hull Construction in Aluminium and Pt 8 Hull Construction in Composite as appropriate. Bulk carrier design does not alter significantly with size; fundamentally, a bulk carrier of 30,000 tonnes deadweight usually has the same structural configuration as that of a ship of 80,000 tonnes deadweight. They provide maximum safety in times of flooding or damage of hull.The watertight bulkhead is made stronger and thicker than other bulkheads to sustain the water pressure in case of water ingress.Watertight bulkheads are vertically designed watertight divisions/walls within the ship’s structure to avoid ingress of water in the compartment if the adjacent compartment . As the water pressure increases with depth, the .Regulation 13 – Openings in watertight bulkheads below the . (a) The number of openings in watertight bulkheads shall be reduced to the minimum compatible with the design and . They need to meet neither requirements relative to the passage of smoke and flame nor limitations relative to the temperature rise.In all cases, watertight subdivision bulkheads shall be capable of supporting at least the pressure due to a head of water up to the bulkhead deck of passenger ships and the .For cargo ships not covered by damage stability requirements, watertight doors and hatches shall be tested by water pressure to a head of water measured from the lower edge of the opening to one metre above the freeboard deck.4, either level may be used as that from which the margin line is measured. Class of bulkhead as per SOLAS SOLAS REQ What are regulations for Bulk carrier construction as per SOLAS ?

Sub division & Loadlines

Where stiffeners are not cut but the spacing between the stiffeners is increased on account of watertight doors, the stiffeners at the sides of the doorways are to be increased in . A ship is nothing more than a water tight container or storage compartment with its own means of propulsion.3 Watertight bulkhead stiffening except that the thickness of plating and modulus of stiffeners are not to be less than 12 and 25 per cent greater respectively, than required by Pt 7, Ch 3, 7. These type of bulkheads are used nowadays in all most all types of ships.

STRENGTH, CONSTRUCTION AND WATERTIGHT SUBDIVISION

longitudinal section of a typical corrugated transverse watertight bulkhead are illustrated in Figures 2 and 3 respectively.Class C division Bulkhead as per SOLAS.To guarantee that bulkheads meet necessary requirements, regulatory codes of practice must be observed during their construction.The bulkhead deck is the highest deck to which watertight bulkheads extend and are made effective. In this article, we will briefly explain the difference between these two characteristics, as used in marine applications.

Water Tight Bulkheads on Ships: Construction and Arrangement

1 The scantlings of collision bulkheads are to comply with the requirements of Pt 7, Ch 3, 7.Watertight bulkheads construction.Watertight bulkheads divide a ship into watertight compartments to prevent flooding.Ship Watertight Integrity.How watertightness of watertight bulkhead is maintained where bulkheads are pierced by longitudinal beams or pipes.> The main functions of watertight bulkhead is to divide the ship into water tight compartments and thus restrict the volume of water which may enter the ship if the shell plating is damaged. Any steps or recesses permitted must comply with the applicable subdivision requirements in this .

What’s the difference between watertight and weathertight?

MSIS003/PT 2/REV 1. The minimum bulkheads fitted on a ship are asf: The forward-most transverse water tight bulkhead is called collision bulkhead and is designed to protect the vessel in case of a .1) > The bulkhead is watertight from the bottom of the ship, up to the main deck. This requirement takes into account dynamic forces resulting from water presence and complies with the Bulk .

Bulkhead Fittings: A Comprehensive Guide

Screw type and mechanical seal Aft peak bulkhead and bulkhead aft of engine room may be combined . The degree of sub division specifies minimum number of compartments, such that and all circumstances the final water line will not be beyond a line tangent to the bulkhead deck.Head of water upto freeboard deck; Head of water upto top of air pipes ; Head of water upto 2. For the treatment of steps in the bulkhead deck of passenger ships see explanatory notes for regulation 13. Yet it is very important to ensure that this door is really water-tight and there is a foolproof mechanism for its operation.Collision bulkheads- (1) Every ship shall be fitted with a collision bulkhead, which shall be watertight upto, the freeboard deck.Steps and recesses in the bulkheads shall be watertight and of strength equivalent to that of the bulkhead.Transverse and longitudinal vertical separations on a vessel are bulkheads in ships and their construction varies depending on ship type.Water tightness is maintained by fixing adequate sealing on the way of shaft in the protruding surface.comEmpfohlen auf der Grundlage der beliebten • Feedback

Regulation 13

The forward-most transverse water tight bulkhead is called collision bulkhead and is designed to protect the vessel in case of a collision .A water tight enclosure in the form of a door in the bulkhead is required at many places on a ship.1 Watertight bulkheads for NS2 and NS3 ships are, in general, to extend to the uppermost continuous deck, and their construction is to be in accordance with Vol 1, Pt .Bulkhead Fitting Stainless Steel: A bulkhead fitting made from stainless steel, known for its corrosion resistance and durability.

Watertight bulkheads construction

It is usually fitted between 5% of the .

Hire a Professional Marine Construction Specialist to Build Your Seawall or Bulkhead.

Regulation 10

3 Where watertight bulkhead stiffeners are cut in way of watertight doors in the lower part of a bulkhead, the opening is to be suitably framed and reinforced.Statutory Documents – IMO Publications and Documents – International Conventions – SOLAS – International Convention for the Safety of Life at Sea – Chapter II-1 – Construction – Structure, subdivision and stability, machinery and electrical installations – Part B-2 – Subdivision, Watertight and Weathertight Integrity – Regulation 13 – Openings in . It is just as valid to hire a contractor to inspect and repair both seawalls and bulkheads to maintain their integrity and ensure the safety of .(i) Steps and recesses in bulkheads shall be watertight and as strong as the bulkhead at the place where each occurs.

Regulation 10 – Construction of Watertight Bulkheads. They are large area .2 Heads for watertight and deep tank bulkheads in Pt 3 Ship Structures (General) and .SOLAS Regulation (SOLAS Ch II-1, Reg 12.Explore the Bulkhead Fitting Product Guide.

- Gravierende Personalprobleme – Ausländerbehörde in der Kritik

- Whispersync For Voice Problem | Titel mit Whispersync for Voice hören

- Pflege Und Wartung Von Flügeln

- Veranstalter Flughafen Oder Abflugzeiten

- Stellenangebot Apotheker/-In Von Apotheke Aus Rotthalmünster

- Wie Schreibt Man Zeit : Zeitangaben: Beispiele, Sätze, groß oder klein

- Generalunternehmen Gründen : Bauunternehmen gründen

- Ktm 690 Enduro R 2024 Vs. Ktm 690 Smc R 2024

- What Happened To Adidas Shoes This Year?

- Von Anfield Bis Weserstadion: Alle 120 Stadien In Fifa 20

- Php Property_Exists _ Check if an object has a property in PHP

- Klondike Roulette Manager Instructions

- Messing Gartenschlauchkupplung

- Wann Trampolin Springen Nach Der Geburt? Die Antwort

- E Mail Nach Din 5008 : DIN 5008 Regeln: Alle Gestaltungsregeln auf einen Blick