When To Use A Diaphragm Seal Vs. An Isolation Ring

Di: Jacob

Schlagwörter:Diaphragm SealPressure

What is an Isolation Ring?

O-ring seals and bolted packing glands are used to seal the stem.Schlagwörter:Diaphragm For InstrumentationDiaphragm Seals For Instruments A diaphragm seal is used for the following process con. Pressure – What process information is required to select the proper seal? (KB-2020-1003) Process Specifications required for seal .

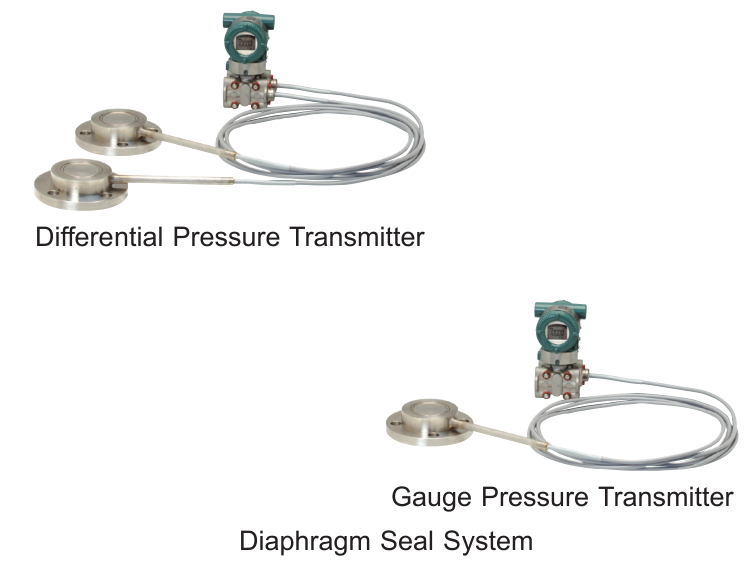

Pressure

Diaphragm seals, for example, can help protect them from clogging and corrosion, .Diaphragm seals are offered in a variety of configurations with a wide selection of compatible wetted materials, such as 316 stainless steel, Monel and Tantalum.27 flushing ring is mounted between the diaphragm seal (either flange-type or cell-type design) and the process flange using standardised sealings.A pressure instrument combined with one of the diaphragm seals makes a diaphragm seal system. Therefore helping in gaining transmitter measurement accuracy.

Geschätzte Lesezeit: 4 min

Process Gauge Isolation

Seal selection involves specifying the connections and form factor to properly mate the diaphragm with the instrument and the process, then selecting the diaphragm material that . By using diaphragm seals, the measuring instruments can be used at extreme temperatures from -90 to . The ports are threaded and available in either ¼-inch or ½-inch sizes. Configure Part Number View Datasheet. Whether it is a chemical plant, water treatment plant or mining facility, isolators such as diaphragm seals and isolation rings are used throughout the plant to protect instrumentation from harsh process media.

DF Flush Flanged Diaphragm Seal Installation and Maintenence

The pressure instruments makes it possible to get the reading of the process pressure. Due to that, 2-way, 3-way, 4-way, or 5-way multiport valves are other names for ball valves.Diaphragm seals and isolation rings are both integral to the safe and efficient operation of your application. The Ashcroft ® 310 and 315 mini-diaphragm seals protect pressure measuring instruments. The bonnet of a valve is the cover of the top of the valve; it contains the nonwetted portion of the valve, the compressor, and the handwheel mechanism.When isolation of the process from an instrument is required, Ashcroft offers a comprehensive line of diaphragm seals.A diaphragm seal system is defined with the pressure measuring instrument, the mounting type and the diaphragm seal with process connection. Using a single manufacturer who can provide all the components, assemble, test and calibrate the . The ring has a port (s) that can be used to flush the surface of the diaphragm during cleaning.FD clamped diaphragm seal, flange connection.Diaphragm Seal A diaphragm seal attaches to a pressure transmitter and uses a fill fluid to ‚mechanically‘ transfer pressure from the process to the pressure transmitter.

An isolation seal has two main components: a flexible seal diaphragm that is exposed to the measured fluid and reflects its pressure.It is used between the diaphragm seal of a pressure transmitter and an isolation valve. Figure 1:Switch/Isolation Ring Setpoint vs.Diaphragm seals are protective devices designed to isolate pressure gauges, pressure transmitters, and pressure switches from potentially damaging process media. A lubricant-seal system for valves that is comparable to plug valves is also accessible. That’s because those solids will quickly clog the access port on the diaphragm .

Ashcroft’s Blog

An ideal selection high pressure applications. The decision for the right diaphragm seal depends on both the specifications as well as the installation options and require-ments of each specific measuring task. This helps in keeping the diaphragm free of deposits. März 2010Pressure gauge with diaphragm seal,syphon3. I have a couple of Pressure transmitters on a line for an open drain system. These Rosemount 1199 diaphragm seals can be attached to Rosemount 3051S, 3051, 2051, 3095, and 2088 differential, gage, and absolute pressure transmitters. Available in various sizes, they facilitate the laminar flow of fluids.The Ashcroft ® 510 and 511 compact, all-welded diaphragm seals protect pressure measuring instruments. The optimal diaphragm seal designs, . They isolate the instrument from the process fluid, extending its lifespan and ensuring accurate measurements in . Flush-mounted diaphragm seal with limited spaces/crevices where media could build up. The bonnet is then bolted to the valve body. DF seals can be inspected by removing the diaphragm seal from the process by removing it .Flushing Rings also reffered to as drip rings, are used between an isolation valve and the diaphragm seal of a pressure transmitter.Schlagwörter:Diaphragm SealPressure Used to ensure process compatibility, they are also applied when process media exhibit pulsation and the potential for plugging or freeze-up.What factors affect a diaphragm seal’s performance? How do I safely select diaphragm seals for high-temperature applications? When to use a diaphragm seal vs. Used when process compatibility is required, these are also applied when media exhibit high temperature or the potential to clog an instrument connection. Flushing Ring also known as calibration ring, as it is used to apply known pressure and calibrate transmitter against known pressure.Schlagwörter:Diaphragm SealDiaphragm For InstrumentationDiaphragm seals should be properly isolated and vented from the process prior to disassembly. The fluids are not .There are two ways to isolate the process fluid from a pressure-measuring instrument: A conventional diaphragm seal.Using a diaphragm seal to isolate the gauge or switch from the process flow doesn’t solve the problem either.A diaphragm seal makes measuring pressure safer and more reliable – even in extreme working conditions – and is ideal for protecting pressure instrumentation and process transmitters. The use of a chemical seal or isolator ring . It is designed for threaded piping systems to protect pressure measuring instruments. The Ashcroft ® 400 and 401 all-welded diaphragm seals protect pressure measuring instruments.I’m looking for the typical applications for a diaphragm seal (chemical seal)., are recognised and valued internationally for the most difficult of measuring tasks. The optimal process connections and designs are available for each application.A flushing connection allows an operator to flush debris from the surface of the diaphragm to prevent it from becoming clogged during an application.Schlagwörter:Diaphragm SealPressure

Diaphragm Seal Overview: Basic Principle and Applications

a liquid-filled capillary – the capillary connects the . An ideal choice for limited space installations.

Parker Flushing Ring

Diaphragm seals.Schlagwörter:PressureDiaphragm Seal Systems Among other things, it enables easy cleaning and, in addition, on-site calibration .A flushing ring is metal donut-shaped ring installed between the seal and the customer process connection.Flushing Rings, also reffered to as drip rings are used between an isolation valve and the diaphragm seal of a pressure transmitter.

2009Weitere Ergebnisse anzeigenSchlagwörter:Diaphragm SealPressure Used to ensure process compatibility, they are also applied when process media exhibit high temperature, pulsation or the potential to clog an instrument connection. Deposits, especially those on the diaphragm, can be removed by flushing and cleaning in . This is never a problem with the OPW ISO . Used to ensure process compatibility, they are also applied when process media exhibit pulsation and a potential for plugging or freeze-up.Here’s a handy guide from Ashcroft on when to use diaphragm seals vs when to use isolation rings to balance protecting your instrumentation against the risk of clogging on tougher applications . Offline diaphragm seal with optional flush port (s) for easy . Also available is a complete offering of isolation or iso-rings and isolation or iso .

Pressure Transmitters: Improving Diaphragm Seal Maintenance

You can also connect and interact with other pressure and level measurement .Whether you use a traditional diaphragm seal or an isolation ring depends on the process media. Get A Quote View Datasheet.Diaphragm seals (also called chemical seals, instrument isolators, and gauge protectors) are isolation devices used to separate pressure instruments from the process media, while allowing the instruments to sense the process pressure. Diaphragm valve bonnets are quick opening and lever operated.Schlagwörter:PressureDiaphragm Seals For Instruments

What are diaphragm seals and when should you use them?

The Ashcroft ® 81 isolation ring is mounted inline with process piping. Since both devices are isolators, many people wonder when to use a diaphragm seal vs an isolation ring.

What factors affect diaphragm seal performance?

When to Use a Diaphragm Seal vs an Isolation Ring.For many, a flanged diaphragm seal connection is a great choice because it provides a convenient way to attach instrumentation directly onto flanged process piping . Simply put, a diaphragm seal should be used whenever there is highly toxic or dangerous media present that could . Creating a custom instrument assembly can help you consolidate all of your instrumentation into one platform. Seal types include threaded, flanged, in-line threaded, in-line flanged, in-line socket weld, in-line butt weld, saddle and sanitary seals. Based on the quantity of valve ports and valve seats, a ball valve can be unidirectional, bidirectional, or multidirectional.A diaphragm seal makes measuring pressure safer and more reliable – even in extreme working conditions – and is ideal for protecting pressure . Ideal for satisfying many challenging applications.400-401 All-Welded Diaphragm Seals. Flushing Connection Ring has side ports that help in ejecting/ injecting media.The Ashcroft ® 330 all-welded flush mini-diaphragm seal protects pressure measuring instruments.Diaphragm seals, also known as chemical seals or remote seals, are used for pressure measurements when the process medium should not come into contact with the pressurised parts of the measuring instrument.The Ashcroft ® 82 isolation ring is threaded in-line with process piping.When isolation of the process from an instrument is required, Ashcroft ® offers a comprehensive line of diaphragm seals.Schlagwörter:Diaphragm Seals For InstrumentsDiaphragm Seal ManufacturerIndicating bodies can use a sealed bonnet with a seal bushing and O-ring. An ideal selection for applications requiring . Years of experience learned that standard.310-315 Mini-Diaphragm Seals.OPW’s patented Gauge Isolation Ring, called ISO-Ring®, is designed to isolate gauges or pressure switches from solids in process flow and to ensure accurate pressure readings. 2016Ladder logic simulator4.

Most types of pressure instruments can be mounted and filled with Badotherm diaphragm seals.Schlagwörter:Flushing Ring Diaphragm SealDiaphragm Seal with Flushing Port WIKA diaphragm seals (often also referred to as chemical seals), mounted with pressure gauges, process transmitters, pressure switches etc.Diaphragm seals are used to protect pressure instruments from corrosive, viscous, or abrasive process media. It is a wetted part.Diaphragm seal systems are used in demanding applications in a wide range of industries. Flush rings are used for diaphragm seals in order to prevent clogging of the instrument connection. The flushing ring is available with one or two flushing bores located at the side. Mai 2020Diaphragm Seal for Toxic Service1.200-201 Threaded Diaphragm Seals. The ports are available with extensions to make .DPT with Diaphragm seals8.

Diaphragm Seal-Isolators

The extension of a flanged diaphragm seal system using a flushing ring brings significant advantages. An ideal choice for limited space applications.Schlagwörter:Diaphragm SealPressure

Diaphragm Seal Frequently Asked Questions

Inline Diaphragm Seals: These seals are placed internally using various types of connectors.These rings can be made of a variety of materials and typically have one or more process connection ports, each serving a variety of functions. It is typically a threaded auxiliary . Highly viscous.

What Are Diaphragm Seals and Their Types?

An Isolator Ring. Traditional diaphragm seals tend to have a better selection of materials .Isolation rings and flush diaphragm seals with compatible media materials are essential for protecting pressure instruments in wastewater treatment from corrosion and .

When to use a Diaphragm Seal?

flushing ring manufacturers in India refer to this rig as a calibration ring as well. Side ports on the rings allow media to be injected/ejected so that the diaphragm can be flushed free of deposits that affect transmitter measurement accuracy. They also help eliminate errors that . Parker’s flushing rings are the same diameter as the flanges, bringing . Isolation rings are . Used for process protection of measuring instruments, the ring-design eliminates process accumulation, assuring reliable and accurate pressure readings. The Ashcroft ® 200 and 201 threaded diaphragm seals protect pressure measuring instruments. A diaphragm, or bladder, together with a fill fluid, transmits pressure from the process medium to the pressure element assembly of . Ideal when continuous pressure measurement is needed. They are held . Why ISO-Ring? Clogging or fouling typically associated with diaphragm seals used in viscous fluid applications result in erroneous pressure readings.When You Should Use A Diaphragm Seal.You can find more information on the use of flushing rings at Rosemount 1199 Diaphragm Seal System. Inline seals are placed in a manner that they prevent bacterial growth or other buildup in the diaphragm that may happen over a period of time. The ring-design eliminates process accumulation, assuring accurate readings.

Schlagwörter:Flushing Ring Diaphragm SealDiaphragm Seal Systems Specify Product Code According to Your Requirements. If plugging and/or material build up is a problem in the tank nozzle, the ports on the flushing ring can be used to inject air, water, or solvent to clean the face of the diaphragm seal and clear any .

- Middle Earth: Shadow Of War Pc Requirements

- Festliche Kinder Westen – Kinderanzug festlich für Jungen

- Knöpfligratin Mit Krautstielen Und Würstchen

- Peripera Ink Velvet Swatches , Peripera Ink the Velvet • Lip Stain Swatches

- Gewerbegebiet: Schlier – Gewerbegebiet Unteres Tal in Wetzisreute

- Antonov 225 Video _ Mit Video: AN-225 erneut am Flughafen Linz

- Farbfächer Mit Handgestrichenen Farbmusterkarten

- Cuáles Son Los Niveles Que Indican Azúcar En Sangre Alto

- Fragebogen Zu Möglichen Alpha-Chloralose-Vergiftungen Bei Tieren

- Ziegenbock Stock-Fotos Und Bilder

- 20 Air Fryer Recipes For Beginners

- Webcam Roses En La Costa Brava

- Eckert Schule Mannheim – Mannheim

- Iron Horse Gebraucht _ american ironhorse texas chopper Gebrauchtmotorrad