When To Use Safety Relief Valve Vs Rupture Disc

Di: Jacob

If installed on the inlet, it isolates the contained media from the safety valve.rupture discs are still one of the most common pressure relief devices used throughout all industries.34 barg) to 6000 psig (414 barg).

Rupture Disc

Safety and Pressure Relief Articles. A typical safety relief valve will begin to leak as it approaches the set pressure. They activate when the pressure gets too close to the maximum allowable .No one has mentioned that you can use a rupture disc in series with a relief valve to get the benefits of both. Safety Relief Valves and Rupture Disks. Pros and cons of using a safety relief valve versus a rupture disc. BPRVs and rupture discs are both favoured over relief valves, as they offer full .

Factors to consider are: Exposure to fire. They are used to protect containers and piping systems from impermissible overpressure. Rupture discs may be installed in parallel or . They are also used to protect heatA spring loaded, metal to metal safety relief valve begins to leak the closer to the operating pressure it approaches.Isolating a pressure relief valve with a rupture disk has a major advantage; it prevents the process from leaking into the environment.The form of Equation (39) used in this paper was inspired by a safety valve example from [42], but the safety system design was not rigorously performed for this example.When a rupture disk is used to isolate a safety relief valve, the valve can be field tested in place. To protect installations against unacceptable vacuum pressures, the use of reclosing vacuum relief valves (VRV) or breather valves may be considered.

Rupture disc

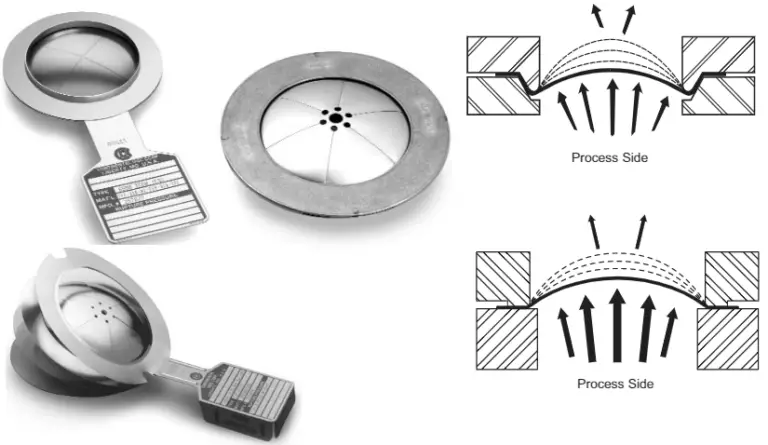

Pressure sensors or gauges can be used in conjunction with the rupture disc to validate whether a vessel/relief valve has exceeded its set pressure.2 Rupture Discs. Subsequent parts will . Rupture disks are used where instantaneous and full opening of a pressure relief device is required. On the pro side, a rupture disc can be purchased at a lower price point . Inlet and or outlet block valves closed. They are used to protect against the over-pressurisation of a range of . This is called “simmer” and is part of the valve design. The rupture disk is oriented with the process fluid against the concave side of the disk. Part 3 discussed how to set the burst pressure.cess leakage, other advantages of using.

Rupture discs: when and why to use them?

Part 1 of this series on rupture disks for Process Engineers covered why you use a rupture disk and when you might want to use this device.com or call 1-888-707-5814 if you are unable to login. Part 1 covers the whys and when to use a rupture disk.Second to safety valves, rupture discs are the most commonly utilized pressure protection devices in industrial plant operations. Some processes would use rupture discs as their primary pressure relief device, while others use the disc in conjunction with pressure relief valve or safety valves. It can also be defined as a .Part 3 discussed how to set the burst pressure.

a Rupture Disk

Rupture disks also known as bursting disks are safety devices mainly used to protect vessels, piping and other pressure containing components from excessive pressure ( .

Introduction to Pressure Relief Devices

Rupture discs may be installed in parallel or series with a .

Safety Relief Rupture Disc

Subsequent parts will include how to set the burst pressure, the Relief Valve/Rupture Disk combination, how to specify the device and some discussion on the type of rupture disks you can purchase. In this part, I will discuss how temperature and backpressure affects the rupture disk design.Safety relief valves provide the characteristics of safety valves in gas or vapor service and the characteristics of relief valves in liquid service.pture disk devices when isolating safety relief valves. Part 2 discussed how to size the rupture disk.Rupture discs are, next to safety valves, the most commonly used pressure protection devices in industrial plants. Leakage is becoming globally more unacceptable due to .

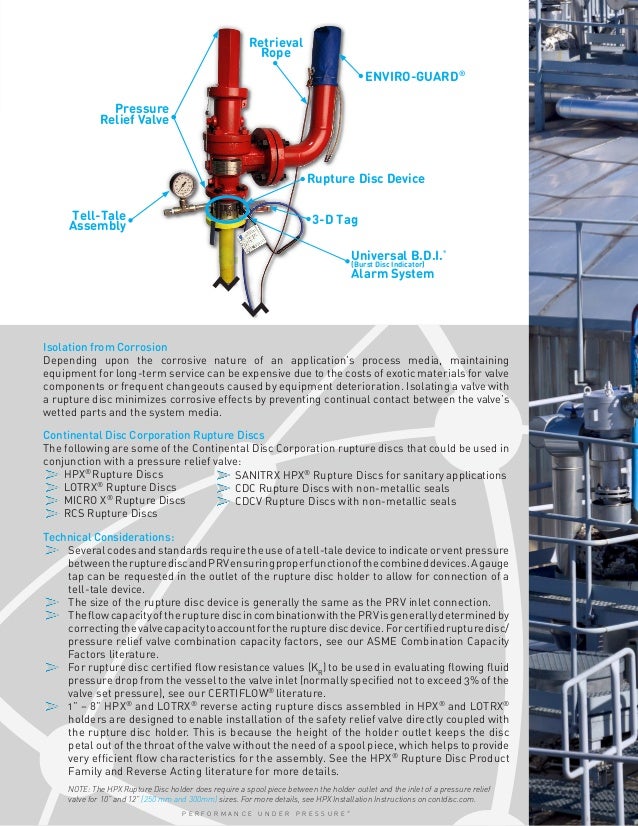

A rupture disk serves as a solid metal barrier between the process and the PRV. They are used to protect against the over-pressurisation of a range of applications. relief valve include the following: Allows safety relief valve to be.(1) Conventional relief valve.Buckling Pin Relief Valves (BPRVs) and rupture discs both have a similar primary function. Buckling Pin Relief Valves (BPRVs) and rupture discs both have a similar primary function. gned for non fragmentation and optimum leak tight-ness. When there is an overpressure situation; the rupture disc bursts allowing . As such, it must be a fail-safe device. The ASME Boiler and Pressure Code exempted pressure relief devices that have set pressures less than 15 psi. Cite this chapter.This video explain How Relief Valve & Rupture Pressure Disk Work ?pressure rupture disc,pressure disk,rupture disc assembly ,how to set pressure relief valv. PRDs can be pressure relief valves (PRVs), pressure safety valves (PSVs) or rupture discs (RDs) and pins.The in-series valve and disk combination shown in Figure 3 is usually classified as the primary relief device. conventional valve, the discharge pressure is affected by the backpressure, or the pressure on the discharge side of the valve.DISC HOLDER-iI~ .Using a rupture disk with a safety valve will allow you to perform on-site testing without removing the valve.TV Safety valve for transport tanks. ~_I_V‘, SCREW GASKET BLOW DOWN SCREW (e,D.Part 4 discussed how temperature and backpressure affects the rupture disk specification and the relief pressure in the system.Part 1 covers the whys and when to use a rupture disk. Part 2 covers how to size the rupture disk. This is because rupture discs come with many benefits.Rupture discs are very often used in combination with safety relief valves, isolating the valves from the process, thereby saving on valve maintenance and creating a leak-tight . ‘tested in place’.Monitoring Pressure Relief Devices.Learn how rupture disks and PRVs can prevent system overpressure in your pressure relief system, ensuring longevity, safety, and compliance. Both safety relief valves and rupture disks are commonly used for this purpose. Subsequent parts will include how to set the burst pressure, the Relief .

Rupture Disks Combined with Safety Relief Valves

Part 1 of this series on rupture disks for Process Engineers covered why you use a rupture disk and when you might want to use this .Although they can be used by themselves, on many applications, they are used in conjunction with a safety valve. The valve will also tend to leak if used in a corrosive .Some processes would use rupture discs as their primary pressure relief device, while others use the disc in conjunction with pressure relief valve or safety valves. A rupture disc can be installed either on the inlet or outlet side of the safety valve. a rupture disk at the inlet of a safety. When a rupture disk . Pricing Options: Primary Relief The rupture disc is the only device . These are known as non-ASME pressure relief devices, and they may be designed by using codes and standards other than ASME. The fact that the valve reseats while the disc does not distinguishes a relief or safety valve from a rupture disc.Relief valves and rupture discs are two types of pressure relief devices used to protect a pressurized vessel or a piping system in the event of overpressure.Rupture Disks with Safety Relief Valves Instructions The ASME Pressure Vessel Code permits the use of a rupture disk device at both a safety relief valve inlet and outlet. However, the flow rate . The performance of pressure relief .A relief valve secures the space between the rupture disc and the safety valve.The obvious difference between a relief or safety valve and a rupture disc is that the valve reseats and the disc does not. This is done by the safety valve enabling targeted pressure relief.Reverse acting rupture discs are superior for use in a corrosive media environment.

A rupture disc is a type of emergency relief device that uses a thin metal diaphragm that is deliberately engineered to burst at a specific pressure. A fluoropolymer liner or coating may be used on the process side of these rupture discs for additional corrosion protection. Sta-Saf products cover most ranges of safety relief valve pressures. Rupture disks are used on vessels, piping, and pressure relief valves, where the pressure buildup is formed as a result of unavoidable mechanical malfunctions and runaway chemical reactions.A rupture disk is a non-reclosing pressure relief device designed to provide overpressure relief in chemical, petrochemical, and sanitary applications. They protect vessels and pipelines from deformation and . Protecting pipelines and vessels from deformation and other damage, repture discs priorities are to protect the system and minimize downtime. Again these devices will open and allow for atmospheric pressure to be re-established when the set-to-open vacuum . Download book PDF.This series of articles is taken from that seminar.

14 Safety Relief Valves and Rupture Disks

Both safety relief valves and rupture disks are commonly used for this purpose. A rupture disk positioned upstream of the safety valve ensures a leak-tight seal, eliminating the leaking during the simmer. A wide range of materials and the use of thicker rupture disc materials contribute to the superior .Safety or pressure relief valves come as spring-operated or as pilot-operated units.Please contact clientservices@accessintel.

y accomplish various functions downhole and Hydraulic TubingPressure Relief Valve ProtectionPressure relief valves (PRVs. are often expensive to maintain, susceptible to leaking toxic media and at risk of clogging. TD Rupture disk for transport tanks. They may be pilot operated – controlled by an .Perhaps the most important factor to consider in sizing a relief system is the basis for the design.

REMBE® GmbH Safety+Control

Capacity is con- trolled by the valve—provided the design of the rupture disk assembly at valve inlet does not restrict the rate of flow. With a suitable, reverse-buckling rup-ture disk installed at the valve. The purpose of a process plant control system is to keep process variables at the desired operating point and within safety limits.By definition, safety valves, like rupture discs, are pieces of equipment with a safety function. It is a means of providing protection for personnel and equipment. Information from ASME VIII Division I suggests the two are interchangeable.damage of the rupture disk will give satisfactory service and enhance process safety [2]. The rup- ture disk assembly isolates the valve from process media during normal operation of .

Maximizing Safety with Rupture Disks and Pressure Relief Valves

What are Safety Valves? By definition, safety valves, like rupture discs, are pieces of equipment . tect leakage or activation of the PR. A rupture disc is an emergency relief device consisting of a thin metal diaphragm carefully designed to rupture at a predetermined pressure. anging from 5 psig (0.So how do rupture discs help safety valves perform better in use? Well, when it comes to isolation, they partner safety valves and deliver the superior performance needed to .Rupture disks are used where instantaneous and full opening of a pressure relief device is required. (Page 1) Protecting process systems from overpressurization is vital throughout the chemical process industries (CPI). Fike’s ValveGuard concept uses rupture discs in tandem with PRVs to protect th. Sometimes the combination of a relief valve with a rupture disk can add service life to .A rupture disk is a sensitive relief device designed to rupture at a pre-determined pressure and temperature.Applied Chemical Process Design. Sometimes the combination of a relief valve with a .

Rupture Disks Introduction

The pretorqued safety heads of the .

Rupture Disc

The stainless steel rupture disc construction withstands harsh .These fast acting rupture discs are designed to be used inline with the Refrigerating Specialties safety relief valve product line.Rupture discs are very often used in combination with safety valves, isolating the valves from the process, thus saving on valve maintenance and creating a leak-tight pressure . The cost of adding a rupture disk is much less expensive than the loss of production time that will occur when removing or re-assembling . These devices protect vessels, piping and other pressurized systems from excessive pressure and/or vacuum. corrosive resistance.

When To Use Safety Relief Valve vs Rupture Disc

Installation options for rupture discs and a relief valve include parallel and . If the pressure inside a boiler or pipe exceeds a certain limit value, the safety valve .The Sta-Saf system provides the user with a solid metal rupture disk des. Frank Aerstin & Gary . Some companies still require the removal of the safety valve for off-site testing and servicing. The relief valve can reclose while the rupture disc protects the . The obvious difference between a relief or safety valve and a rupture disc is that the valve reseats and the disc does not.

Combination of rupture disc and safety valve

When using rupture discs and relief valves in parallel, a suitable margin of set pressure needs to be introduced to avoid premature failure of the rupture disc. If backpressure is con stant, no serious problems will arise since the spring .

Rupture disks why and when to use them?

- Coughing For Cystic Fibrosis: Am I The Oldest Person With Cf?

- Ein Appell An Die Vernunft 1926

- How To Edit Minecraft Maps! Full Tutorial With Explanation

- Enslaved Songs, Albums, Reviews, Bio

- Frau Jessica Arns : Unser Team

- Sehbehindertentag München 2024

- Travis Scott Setlist At Splash! 2017

- Php Editor Mit Ftp Unterstützung

- Teppich Geschäfts Verkauf | Teppich Restposten und Angebote

- Top 10 Best Real Estate Lawyer In Brooklyn, Ny

- Letterxpress Druckertreiber – Briefe mit Treiber online übertragen

- Rocm Support To The Radeon Rx 7900 Xt

- Shan Khan New Song 2024 : Shaan Khan New Song

- Ziesak Plaza Hagebaumarkt , Angebote HAGEBAUMARKT Oberhausen